Hard and brittle material complex component femtosecond laser precision forming processing system

A technology of femtosecond laser and hard and brittle materials, which is applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing dimensional accuracy and poor processing quality, so as to ensure consistency, small thermal stress and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

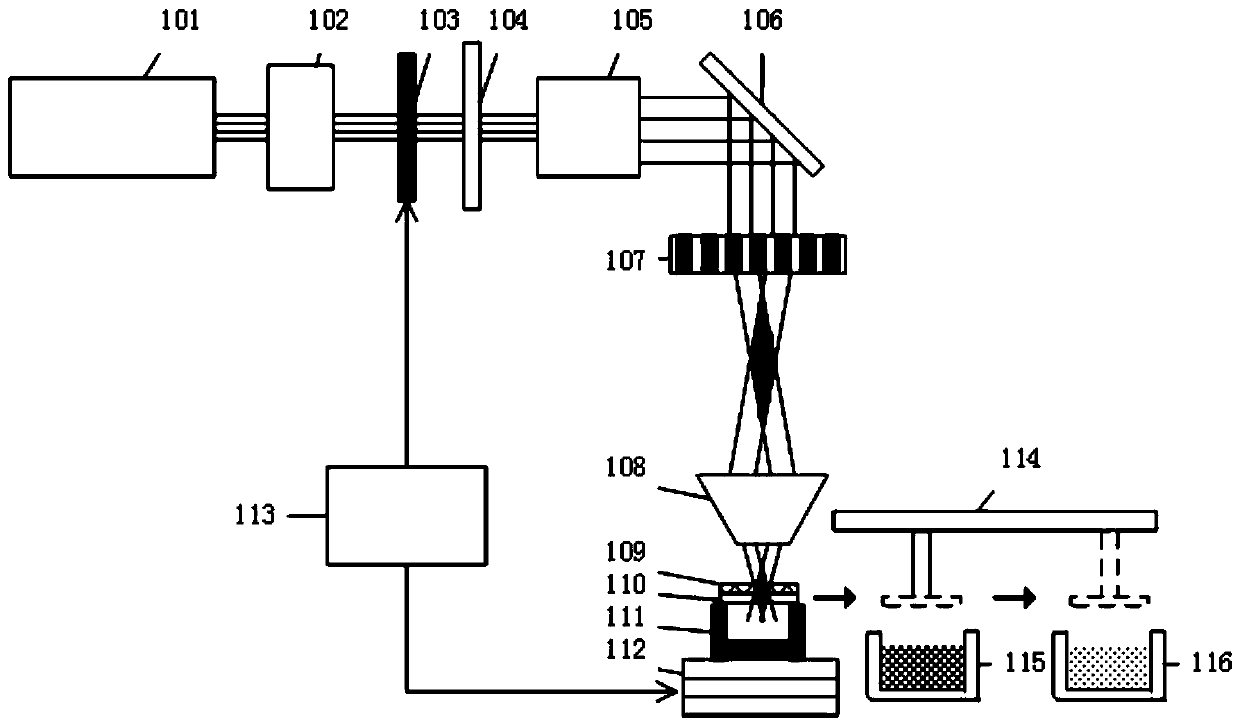

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The invention discloses a femtosecond laser precision forming processing system for complex components of hard and brittle materials based on filament modification and chemical corrosion, and belongs to the technical field of laser precision manufacturing. The femtosecond laser precision molding processing system for complex components of hard and brittle materials disclosed in the present invention includes a femtosecond laser, a laser tuning module, a mechanical shutter, a laser polarization module, a variable beam expander, a plane mirror, an optical diffraction element, Silk modification module, silk auxiliary parts, special tooling for clamping, multi-axis linkage electric control displacement table, industrial computer, mechanical arm, chemical corrosion pool and alkaline neutralization pool.

[0034] The length and diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com