Method for inhibiting reduction degradation of zinc-containing dust pellets in rotary hearth furnace

A rotary hearth furnace and pelletizing technology, which is used in the field of metalized pellets returning to blast furnace, converter/electric furnace or sintering process, can solve the problems of reducing system productivity, reducing metalized pellets, reducing economic benefits, etc., to increase environmental protection and efficiency. Social benefits, improved zinc recovery, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

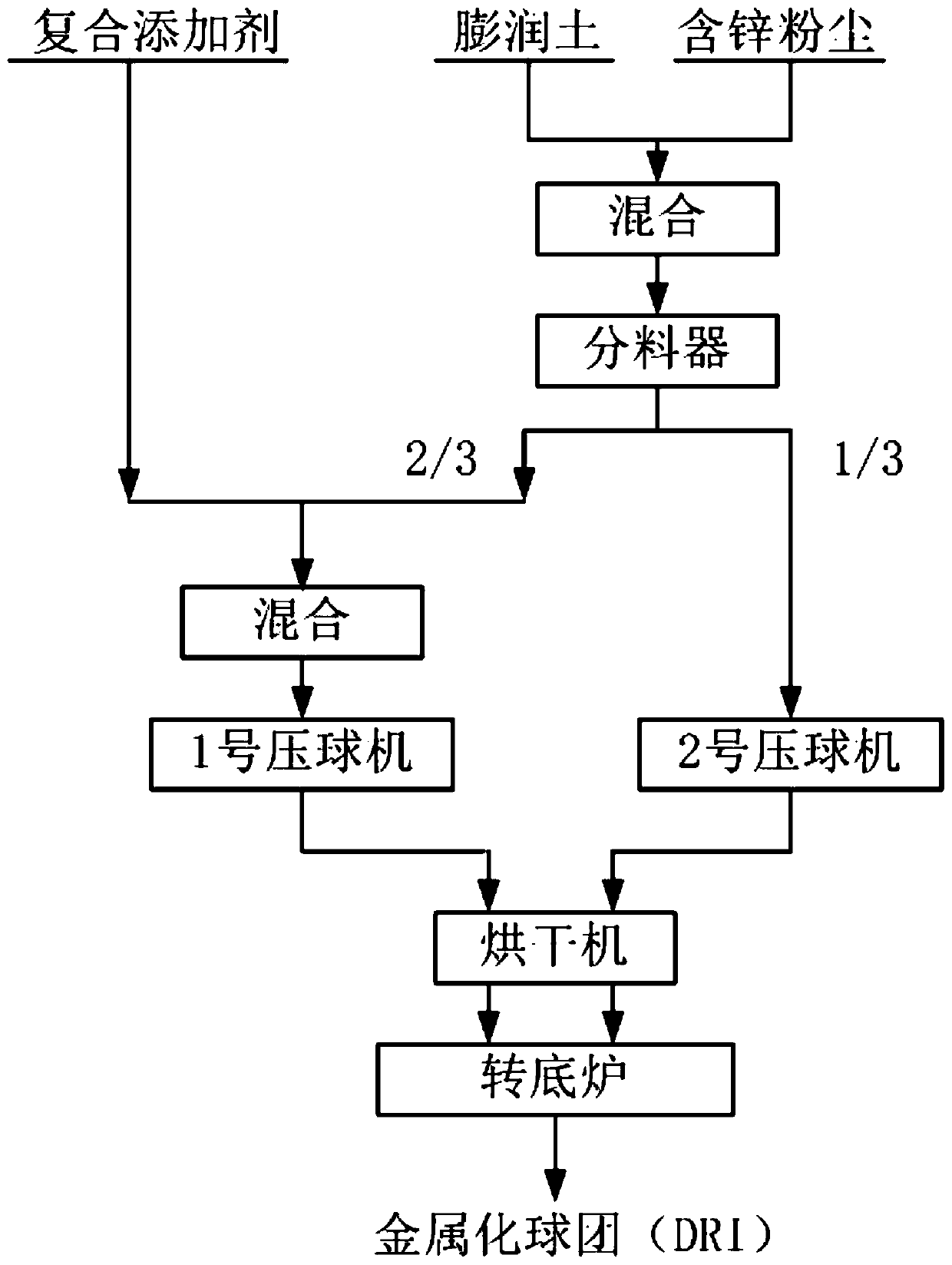

[0071] A steel plant mixes various dusts. After mixing, the main chemical components of zinc-containing dust are: TFe: 46.91%, Zn: 3.88%, C: 16.64%, CaO: 0.4%, MgO: 0.91%, SiO 2 : 5.75%, Al 2 o 3 : 1.08%, composite additive bonding index 85. The mixed zinc-containing dust is firstly mixed with bentonite according to the mass ratio of 100:3, and the mixture is divided into two parts through the distributor, one part accounts for 2 / 3, and the other part accounts for 1 / 3. Such as figure 1 As shown, 2 / 3 of the zinc-containing dust mixture and composite additives are further mixed evenly according to the mass ratio of 100:13, and sent to the briquetting machine to briquette. The pressed No. 1 pellet enters the dryer for drying. The pellets dried to a water content of ≤2% are sent to the rotary hearth furnace for roasting and reduction; 1 / 3 of the zinc-containing dust mixture is directly sent to another briquetting machine for briquetting, and the pressed No. 2 pellets enter the ...

Embodiment 2

[0073] A steel plant mixes various dusts. After mixing, the main chemical components of zinc-containing dust are: TFe: 42.91%, Zn: 16.21%, C: 17.64%, CaO: 0.65%, MgO: 0.31%, SiO 2 : 3.21%, Al 2 o 3 : 0.29%, composite additive bonding index 92. The mixed zinc-containing dust is firstly mixed with bentonite according to the mass ratio of 100:3, and the mixture is divided into two parts through the distributor, one part accounts for 2 / 3, and the other part accounts for 1 / 3. Such as figure 1 As shown, 2 / 3 of the zinc-containing dust mixture and composite additives are further mixed evenly according to the mass ratio of 100:15, and sent to the briquetting machine to briquette. The pressed No. 1 pellet enters the dryer for drying. The pellets dried to a water content of ≤2% are sent to the rotary hearth furnace for roasting and reduction; 1 / 3 of the zinc-containing dust mixture is directly sent to another briquetting machine for briquetting, and the pressed No. 2 pellets enter th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com