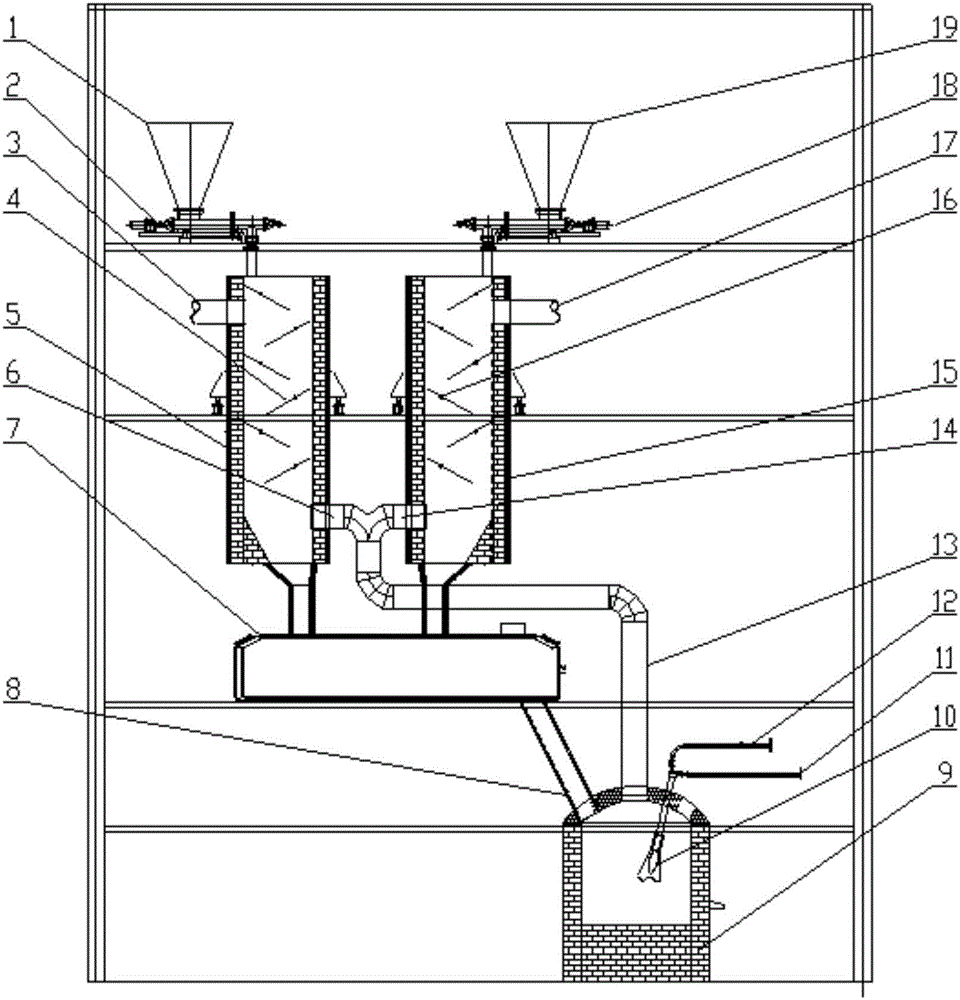

System and method for producing calcium carbide through high-temperature ball-pressing double-vertical-furnace

A technology of shaft furnace and briquette, which is applied in coking oven, petroleum industry, special form of dry distillation, etc. It can solve the problems of high production energy consumption, high power consumption, low output, etc., achieve the degree of guarantee and efficiency, and reduce the pulverization rate , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

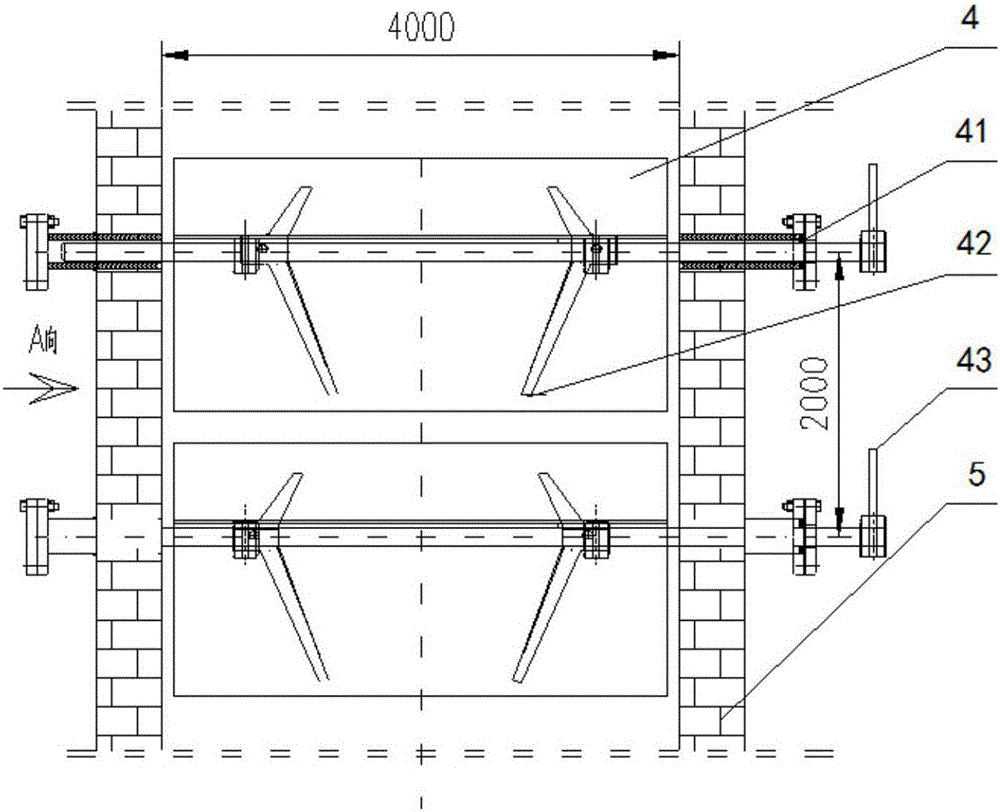

[0051] Limestone powder is first put into the hopper 1, and then sent into the lime shaft furnace 5 according to a certain ratio and speed through the speed-regulating feeder 2 at the lower part. The limestone powder slides down along the baffle plate 4 in the shaft furnace 5 and reacts under the condition of high-temperature flue gas at the same time. The falling speed and reaction time of the limestone powder are controlled by adjusting the angle of the baffle plate. Limestone powder reacts at high temperature to form CaO and CO 2 , CO 2 And high-temperature flue gas is discharged from the exhaust port 3 and enters the next process. The quicklime powder enters the briquetting machine 7 through the feeding port to participate in briquetting.

[0052] The pulverized coal is put into the hopper 19, and sent into the high-temperature pyrolysis furnace 15 according to a certain ratio and speed through the speed-regulating feeder 18 at the lower part. The pulverized coal powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com