Preparation method of novel hydrogen catalytic combustion non-noble metal catalyst

A catalytic combustion and non-precious metal technology, which is applied in the direction of combustion methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of high cost of catalytic combustion and difficult promotion of catalytic combustion, and reduce production and preparation costs. The effect of ensuring safe discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

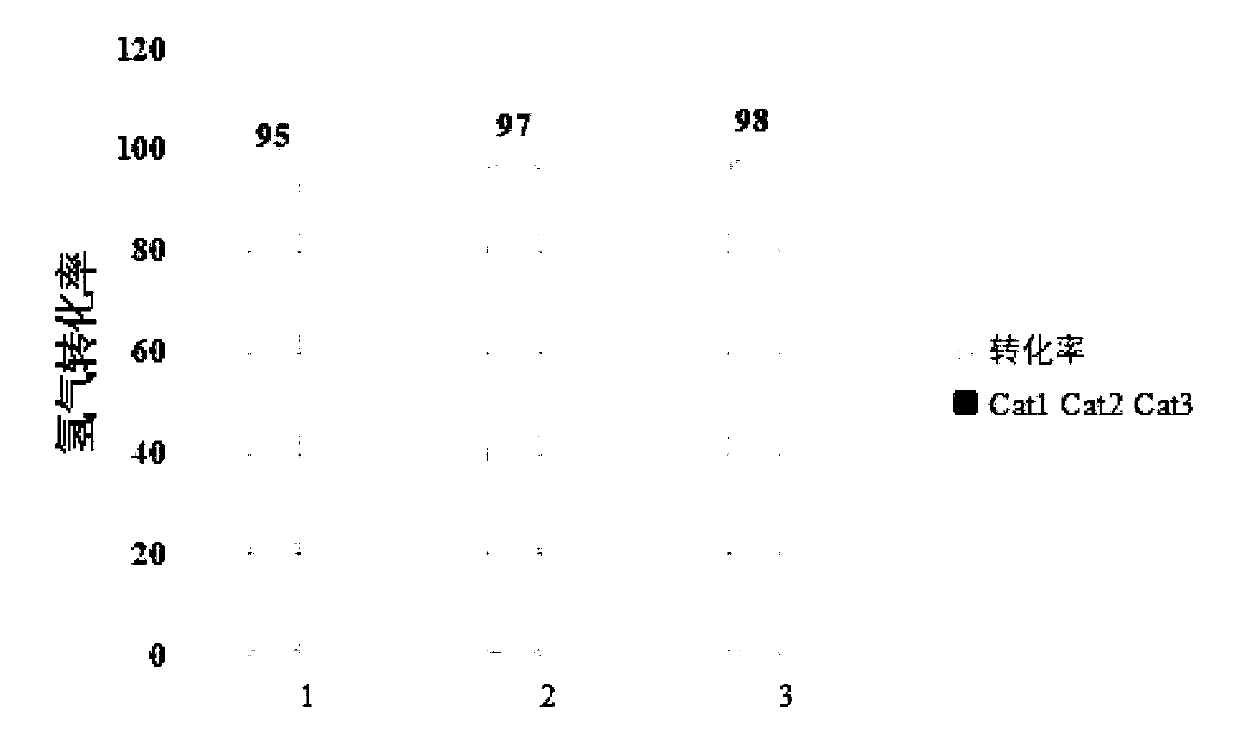

Embodiment 1

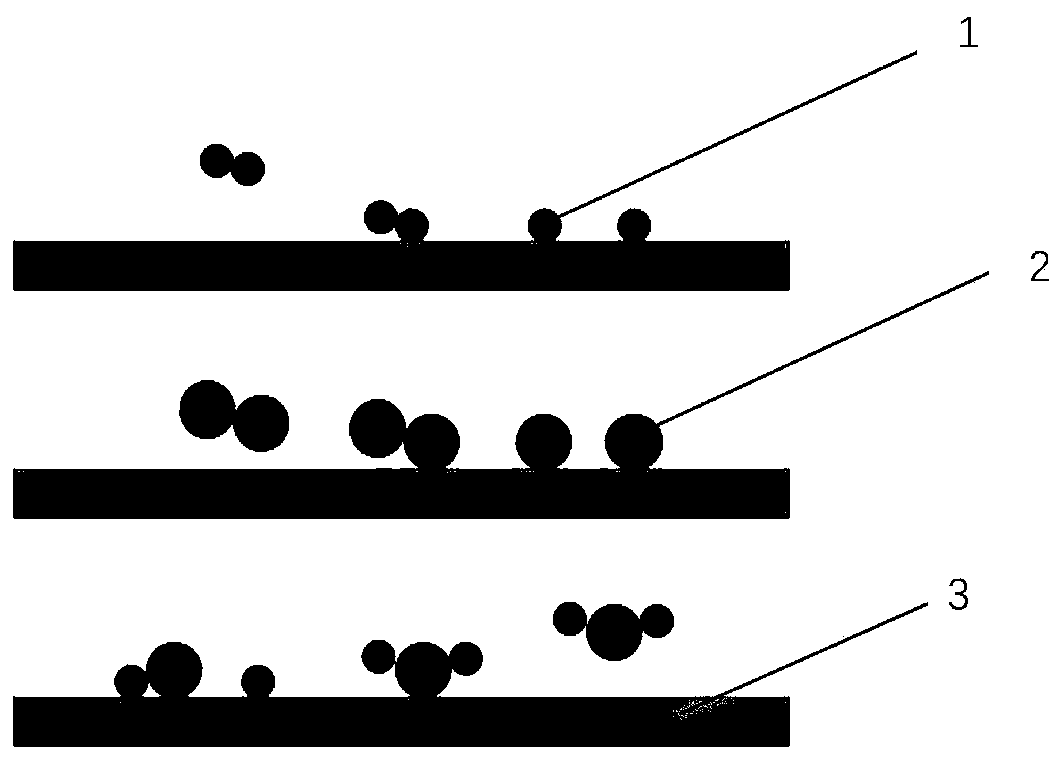

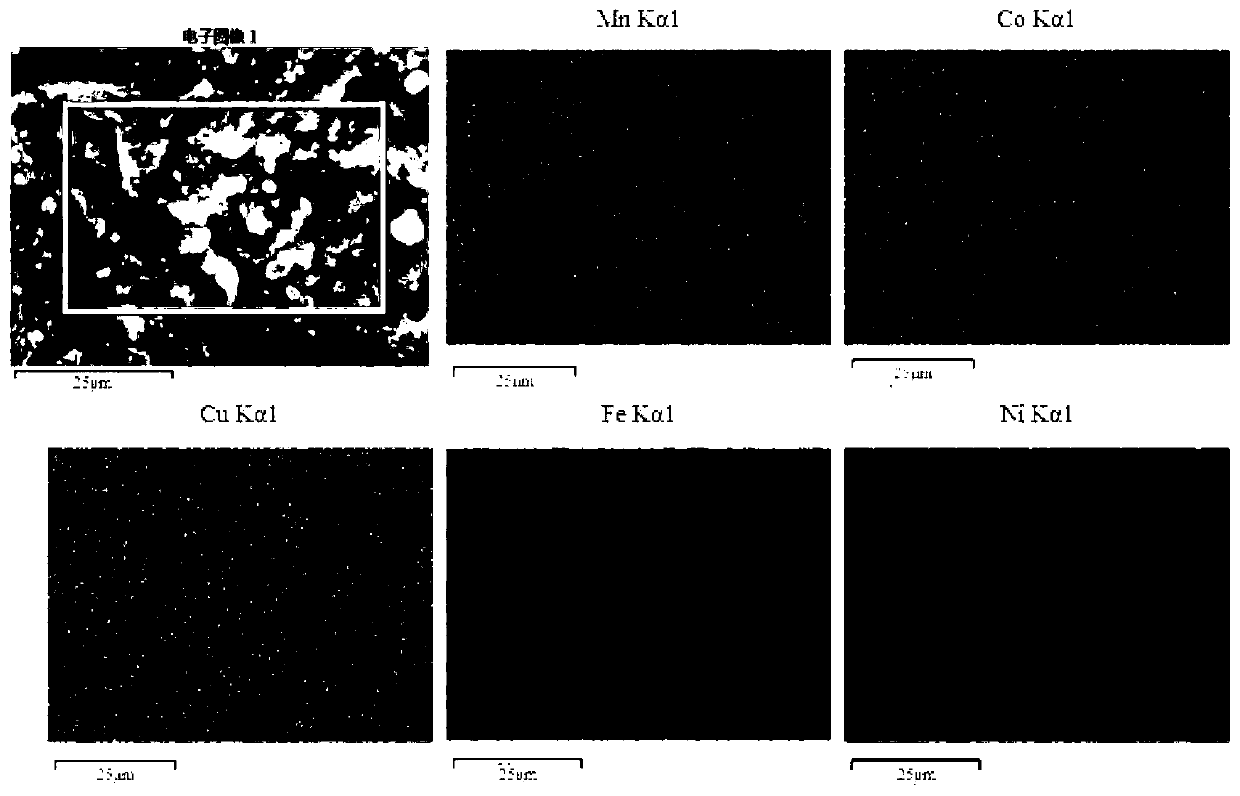

[0021] 1Mn-1Co-1Cu-1Fe-1Ni / γ-Al 2 o 3 / Preparation of cordierite

[0022] Weigh 100g cordierite Mg 2 al 4 Si 5 o 18 Honeycomb ceramics as the main component as the first carrier, 30g γ-Al 2 o 3 The powder is formulated into a slurry, which is uniformly coated on the cordierite. Get carrier γ-Al 2 o 3 / cordierite.

[0023] Weigh 50.2g Mn(NO 3 ) 2 4H 2 O, 58.2g Co(NO 3 ) 2 ·6H 2 O, 37.5g Cu(NO 3 ) 2 , 80.8gFe(NO 3 ) 3 9H 2 O and 58.2g Ni(NO 3 ) 2 ·6H 2 O is fully dissolved in distilled water to obtain 100ml of 2mol / L Mn(NO 3 ) 2 Aqueous solution, 100ml of 2mol / L Co(NO 3 ) 2 Aqueous solution, 100ml of 2mol / L Cu(NO 3 ) 2 Aqueous solution, 100ml of 2mol / LFe(NO 3 ) 3 Aqueous solution, 100ml of 2mol / L Ni(NO 3 ) 2 aqueous solution. Measure 3.708ml Mn(NO 3 ) 2 Aqueous solution, 3.708mlCo(NO 3 ) 2 ·6H 2 O aqueous solution, 3.708ml Cu(NO 3 ) 2 Aqueous solution, 3.708ml Fe(NO 3 ) 3 9H 2 O aqueous solution and 3.708ml Ni(NO 3 ) 2 ·6H 2 O is ...

Embodiment 2

[0027] 1Mn-2Co-2Cu-2Fe-2Ni / γ-Al 2 o 3 / Preparation of cordierite

[0028] Weigh 100g cordierite Mg 2 Al 4 Si 5 o 18 Honeycomb ceramics as the main component as the first carrier, 30g γ-Al 2 o 3 The powder is formulated into a slurry, which is uniformly coated on the cordierite. Get carrier γ-Al 2 o 3 / cordierite.

[0029] Weigh 50.2gMn(NO 3 ) 2 4H 2 O, 58.2gCo(NO 3 ) 2 ·6H 2 O, 37.5gCu(NO 3 ) 2 , 80.8gFe(NO 3 ) 3 9H 2 O and 58.2gNi(NO 3 ) 2 ·6H 2 O is fully dissolved in distilled water to obtain 100ml of 2mol / LMn(NO 3 ) 2 Aqueous solution, 100ml of 2mol / LCo(NO 3 ) 2 Aqueous solution, 100ml of 2mol / LCu(NO 3 ) 2 Aqueous solution, 100ml of 2mol / LFe(NO 3 ) 3 Aqueous solution, 100ml of 2mol / L Ni(NO 3 ) 2 aqueous solution. Measure 2.078ml mol / LMn(NO 3 ) 2 Aqueous solution, 4.155ml Co(NO 3 ) 2 ·6H 2 O aqueous solution, 4.155ml Cu(NO 3 ) 2 Aqueous solution, 4.155ml Fe(NO 3 ) 3 9H 2 O aqueous solution and 4.155ml Ni(NO 3 ) 2 ·6H 2 O is m...

Embodiment 3

[0034] 1Mn-3Co-3Cu-3Fe-3Ni / γ-Al 2 o 3 / Preparation of cordierite

[0035] Weigh 100g cordierite Mg 2 Al 4 Si 5 o 18 Honeycomb ceramics as the main component as the first carrier, 30g γ-Al 2 o 3 The powder is formulated into a slurry, which is uniformly coated on the cordierite. Get carrier γ-Al 2 o 3 / cordierite.

[0036] Weigh 50.2g Mn(NO 3 ) 2 4H 2 O, 58.2g Co(NO 3 ) 2 ·6H 2 O, 37.5g Cu(NO 3 ) 2 , 80.8gFe(NO 3 ) 3 9H 2 O and 58.2g Ni(NO 3 ) 2 ·6H 2 O is fully dissolved in distilled water to obtain 100ml of 2mol / L Mn(NO 3 ) 2 Aqueous solution, 100ml of 2mol / L Co(NO 3 ) 2 Aqueous solution, 100ml of 2mol / L Cu(NO 3 ) 2 Aqueous solution, 100ml of 2mol / LFe(NO 3 ) 3 Aqueous solution, 100ml of 2mol / L Ni(NO 3 ) 2 aqueous solution. Measure 1.443ml mol / LMn(NO 3 ) 2 Aqueous solution, 4.329ml Co(NO 3 ) 2 ·6H 2 O aqueous solution, 4.329ml Cu(NO 3 ) 2 Aqueous solution, 4.329ml Fe(NO 3 ) 3 9H 2 O aqueous solution and 4.329ml Ni(NO 3 ) 2 ·6H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com