A kind of soluble bisfluorosulfonimide lithium/magnesium lithium silicate coated diaphragm for lithium ion battery and preparation method thereof

A technology of lithium bisfluorosulfonyl imide and lithium magnesium silicate, which is applied in the repair/maintenance of secondary batteries, secondary batteries, battery pack components, etc., can solve the problems affecting the rate discharge performance and cycle performance of lithium-ion batteries, Issues such as the promotion effect of the battery and the weakening of the adhesion of the separator coating are not fully considered to achieve the effects of improving battery capacity and electrochemical performance, reducing SEI film impedance, and smoothing the interface of the separator and pole piece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

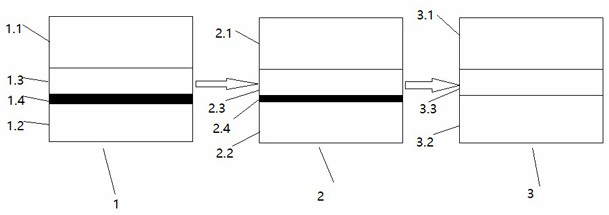

[0034] A lithium-ion battery is coated with a soluble bisfluorosulfonimide lithium / lithium magnesium silicate diaphragm, the base film is polyethylene, the base film is coated with a ceramic coating on the side facing the positive electrode, and the base film is facing the negative electrode The surface coating on one side includes a coating of lithium magnesium silicate, battery-grade high-purity lithium bisfluorosulfonimide, and polymethyl methacrylate.

[0035] A preparation method for a soluble lithium bisfluorosulfonimide / lithium magnesium silicate coating separator for a lithium ion battery, comprising the following steps:

[0036] (1) Lithium magnesium silicate and methyl methacrylate were mixed according to the weight ratio of 1:10 and ultrasonically oscillated, and the lithium magnesium silicate / polymethyl methacrylate composite particle emulsion was prepared by in-situ emulsion polymerization. The composite emulsion was prepared into lithium magnesium silicate / polyme...

Embodiment 2

[0040]A lithium-ion battery uses a soluble bisfluorosulfonimide lithium / magnesium lithium silicate to coat the diaphragm, the base film is polypropylene, the base film is coated with a ceramic coating on the side facing the positive electrode, and the base film is facing the negative electrode The surface coating on one side includes a coating made of lithium magnesium silicate, battery-grade high-purity lithium bisfluorosulfonimide, and polymethylmethacrylate.

[0041] A method for preparing a soluble lithium bisfluorosulfonyl imide / lithium magnesium silicate coating separator for a lithium battery, comprising the following steps:

[0042] (1) Lithium magnesium silicate and methyl methacrylate were mixed according to the weight ratio of 1:20 and ultrasonically oscillated, and lithium magnesium silicate / polymethyl methacrylate composite particle emulsion was prepared by in-situ emulsion polymerization, and sprayed The composite emulsion was prepared into lithium magnesium sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com