Coating technology

A coating process and coating technology, applied in covering/lining, construction, building construction, etc., can solve the problems of high cost, poor material quality and performance, waterproof and short durability, and achieve cost-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

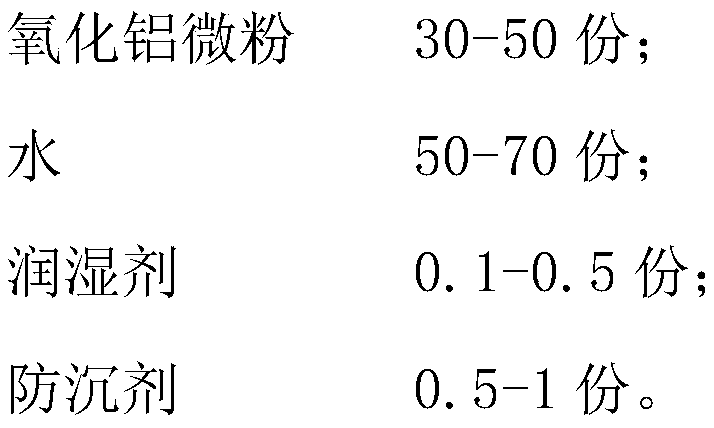

[0068] Embodiment 1: the preparation of aqueous cleaning agent

[0069] Take 40 parts of alumina micropowder, 60 parts of water, 0.3 parts of BYK-346, 0.7 parts of BYK-425, add the above materials in sequence, and stir evenly, the speed is controlled at about 500 rpm, and the time is controlled at about 5 minutes. Get an aqueous cleaner.

[0070] Take 30 parts of alumina micropowder, 70 parts of water, 0.1 part of BYK-346, 0.5 part of BYK-425, add the above materials in sequence, and stir evenly, the speed is controlled at about 500 rpm, and the time is controlled at about 5 minutes. Get water-based cleaning agent 2.

[0071] Take 50 parts of alumina micropowder, 50 parts of water, 0.5 part of BYK-346, and 1 part of BYK-425, add the above materials in sequence, and stir evenly, the speed is controlled at about 500 rpm, and the time is controlled at about 5 minutes. Get water-based cleaning agent 3.

Embodiment 2

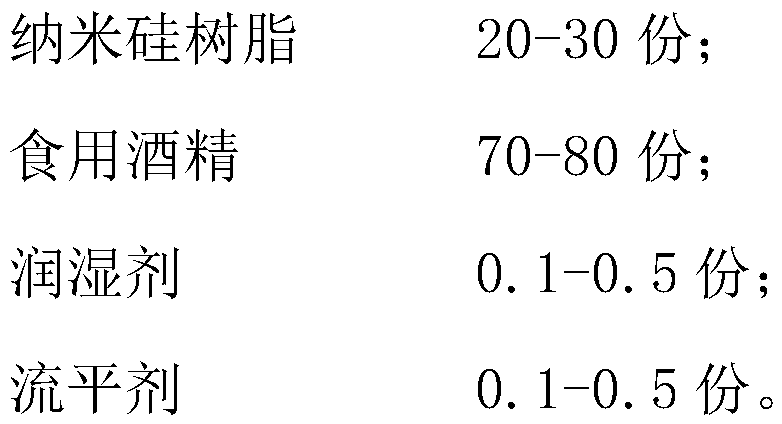

[0072] Embodiment 2: the preparation of interface agent

[0073] Take 25 parts of nano-silicone resin, 75 parts of edible alcohol, 0.3 parts of Tego-245, 0.3 parts of Tego-410, add the above materials in sequence, and stir evenly. The speed is controlled at about 700 rpm and the time is controlled at about 5 minutes. Interface agent 1 was prepared.

[0074] Take 20 parts of nano-silicone resin, 80 parts of edible alcohol, 0.2 parts of Tego-245, 0.2 parts of Tego-410, add the above materials in sequence, and stir evenly. The speed is controlled at about 700 rpm and the time is controlled at about 5 minutes. Interface agent 2 is prepared.

[0075] Take 30 parts of nano-silicone resin, 70 parts of edible alcohol, 0.5 parts of Tego-245, 0.5 parts of Tego-410, add the above materials in sequence, and stir evenly, the speed is controlled at about 700 rpm, and the time is controlled at about 5 minutes. The interface agent 3 is prepared.

Embodiment 3

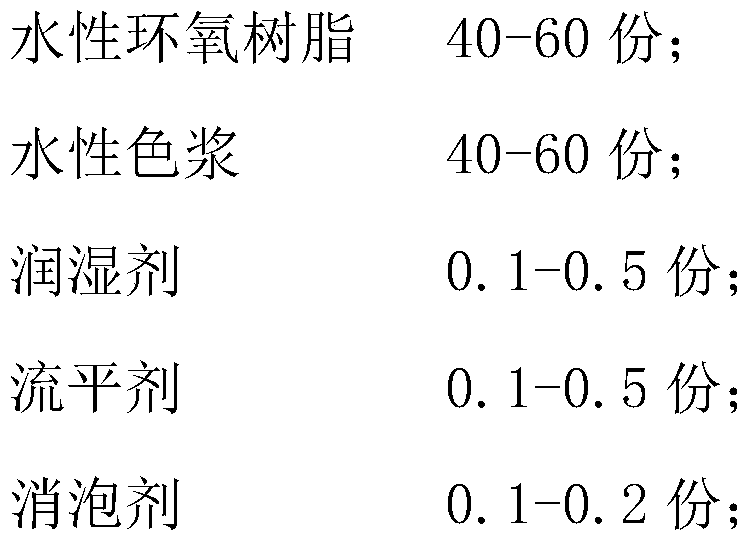

[0076] Embodiment 3: the preparation of waterborne two-component waterproof primer

[0077] Take 50 parts of water-based epoxy resin, 50 parts of water-based color paste, 0.3 parts of BYK-346, 0.3 parts of BYK-333, 0.1 part of BYK-028, and add them to the mixing tank in turn, and stir for 20 minutes according to the stirring speed of 600 rpm , A water-based two-component waterproof primer was prepared.

[0078] Take 40 parts of water-based epoxy resin, 60 parts of water-based color paste, 0.3 parts of BYK-346, 0.3 parts of BYK-333, 0.1 part of BYK-028, add them to the mixing tank in turn, and stir for 20 minutes at a stirring speed of 800 rpm , to prepare water-based two-component waterproof primer II.

[0079] Take 60 parts of water-based epoxy resin, 40 parts of water-based color paste, 0.3 parts of BYK-346, 0.3 parts of BYK-333, and 0.1 part of BYK-028, and add them to the mixing tank in turn, and stir for 20 minutes at a stirring speed of 700 rpm , to prepare a water-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com