Electric-heating floor system and electric-heating floor

An electric heating floor and floor technology, which is applied in the field of building decoration, can solve the problems of high requirements for connecting power lines, potential safety hazards, and short contact distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] (Example 1, electric heating floor)

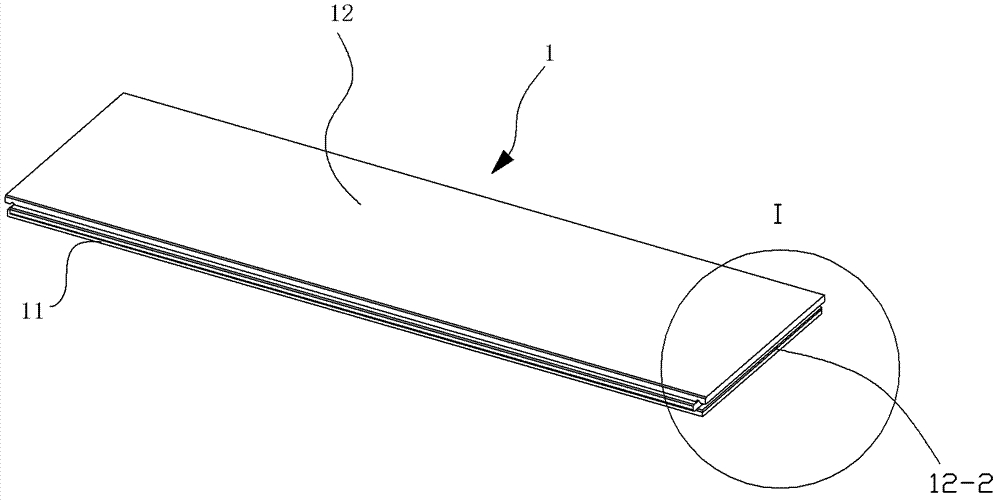

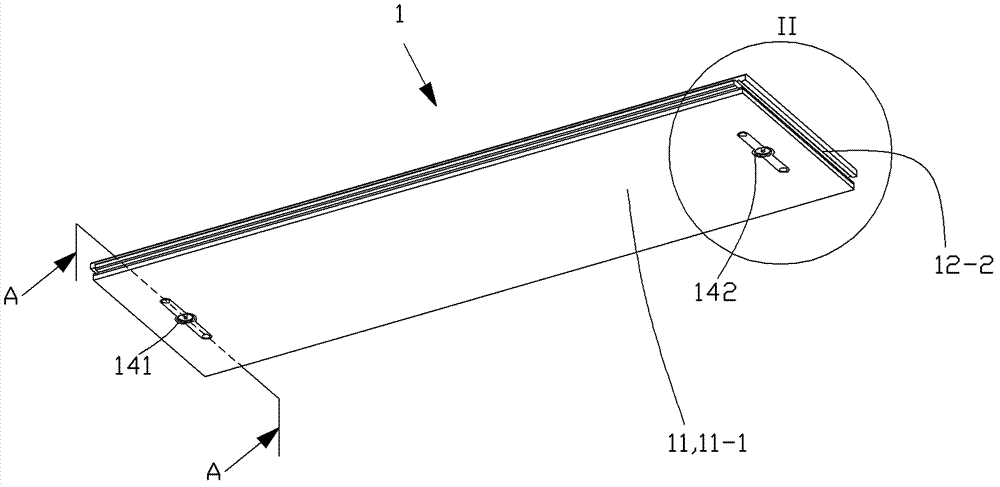

[0117] See Figure 1 to Figure 4 with Figure 7 , The electric heating floor 1 of this embodiment includes a bottom plate 11 , an upper plate 12 , a heating plate 13 and a plug assembly 14 .

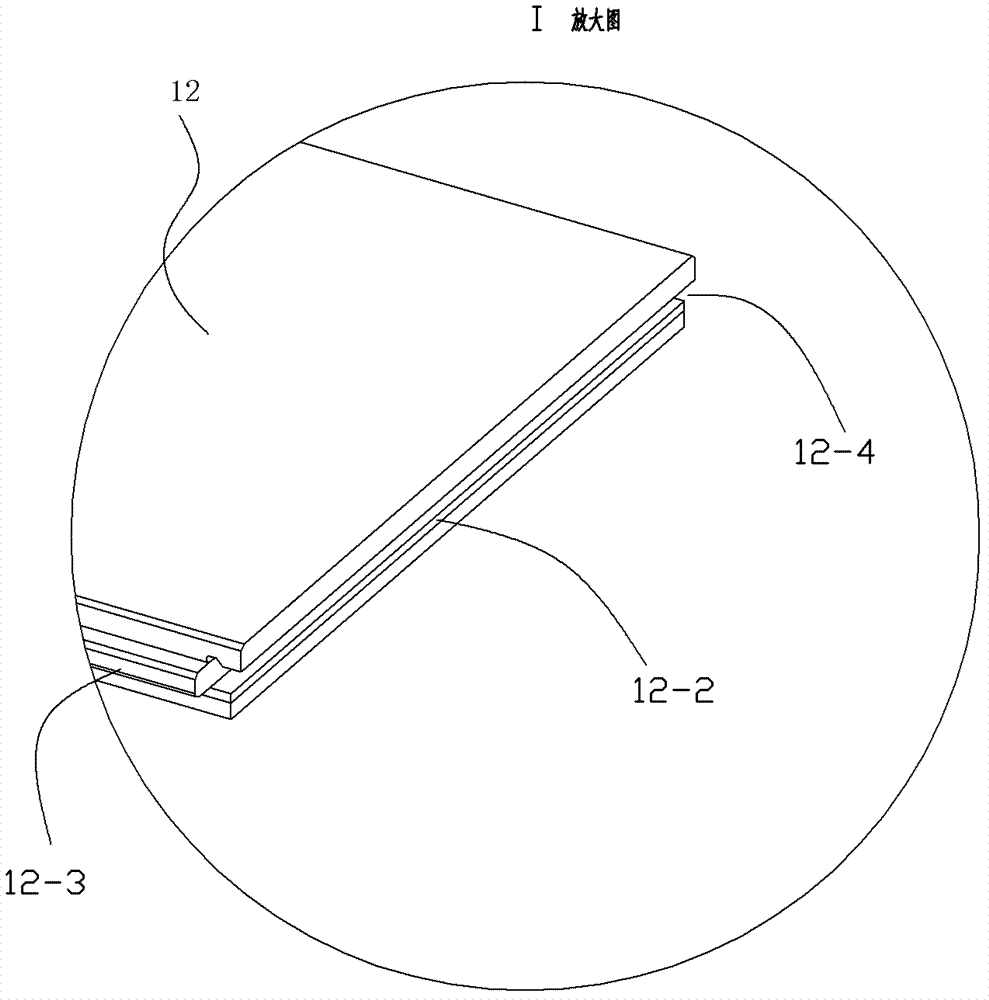

[0118] See figure 1 , image 3 with Figure 7 , the upper plate 12 is a homogeneous piece of wood, including a main body part 12-1 whose basic shape is a cuboid, a tenon part 12-3 located on the front side of the main part 12-1, and a tenon part located on the rear side of the main part 12-1. The insertion groove part 12-4 of the body part 12-1 and the fastening groove part 12-2 located on the left and right sides of the main body part 12-1. The insertion tenon part 12-3 is the position where the insertion grooves of the electric heating floors adjacent to the front side are connected and matched with each other during use, and the insertion groove part 12-4 is the insertion connection of the electric heating floors adjacent to the rear s...

Embodiment 2

[0129] (Example 2, electric heating floor system)

[0130] See Figure 11 with Figure 12 , when this embodiment describes the electric heating floor system, its front and rear, left and right, and up and down directions are the same as those described in Embodiment 1, that is, the Figure 11 The length direction of the mounting base 2 is the front-to-back direction, that is, Figure 11 The lower left in the middle is the front side, and the upper right is the rear side, that is, the Figure 12 The up, down, left, and right directions of are the described up, down, left, and right directions.

[0131] See Figure 27 , The electric heating floor system of this embodiment includes an electric heating floor, an installation base 2, a plug-in blocking member 31 and a power supply system. The power supply system includes a power supply line 600 and a keel line 400 . The electric heating floor adopts the electric heating floor 1 of Embodiment 1.

[0132] See Figure 11 , the...

Embodiment 3

[0158] (Embodiment 3, electric heating floor system)

[0159] See Figure 28 with Figure 29 , the rest of this embodiment is the same as that of Embodiment 2, the difference is that: the keel socket 4 also includes a wiring barrel 43, and the wiring barrel 43 and the copper sleeve 42 are an integral piece of the same material. When making this integral piece, a small piece The rectangular copper sheet 44 is provided with one or two bending grooves 44-2 (two in this embodiment) along the width direction, and a small section of copper sheet is reserved as the connection part 44-1. Then, 3 to 5 grooves (3 in this embodiment) are horizontally provided at equal intervals on the copper sheet located on the right side. Then the copper sheet is rolled into a cylindrical shape along the width direction, thereby forming the wiring barrel 43 on the left side of the connection part 44-1 and the copper sleeve 42 on the right side of the connection part 44-1, and three horizontally arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com