Automobile saddle opening end cover machining method through inner ring surface induction quenching hardening

A technology of induction hardening and processing methods, which is applied in the field of auto parts, can solve the problems of complex replacement process of the open end cover of the worn saddle, high contact pressure, insufficient oil lubrication, etc., to reduce deformation of parts, improve hardness, and improve heating efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

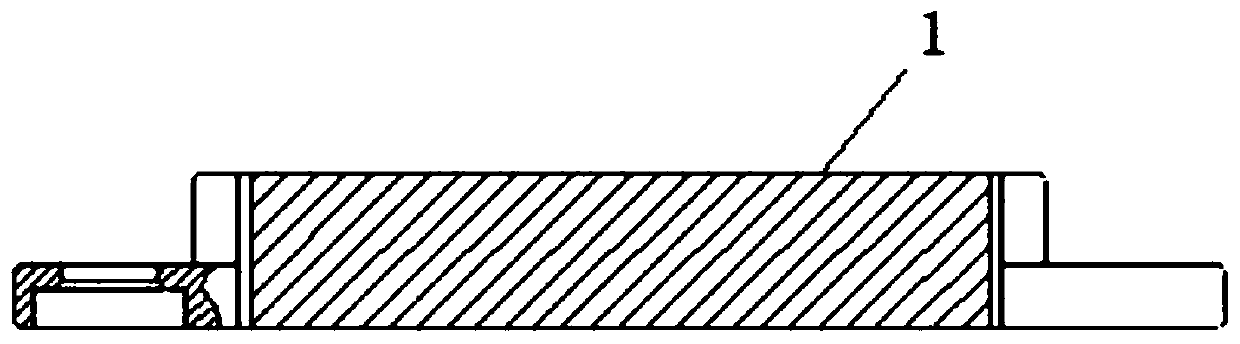

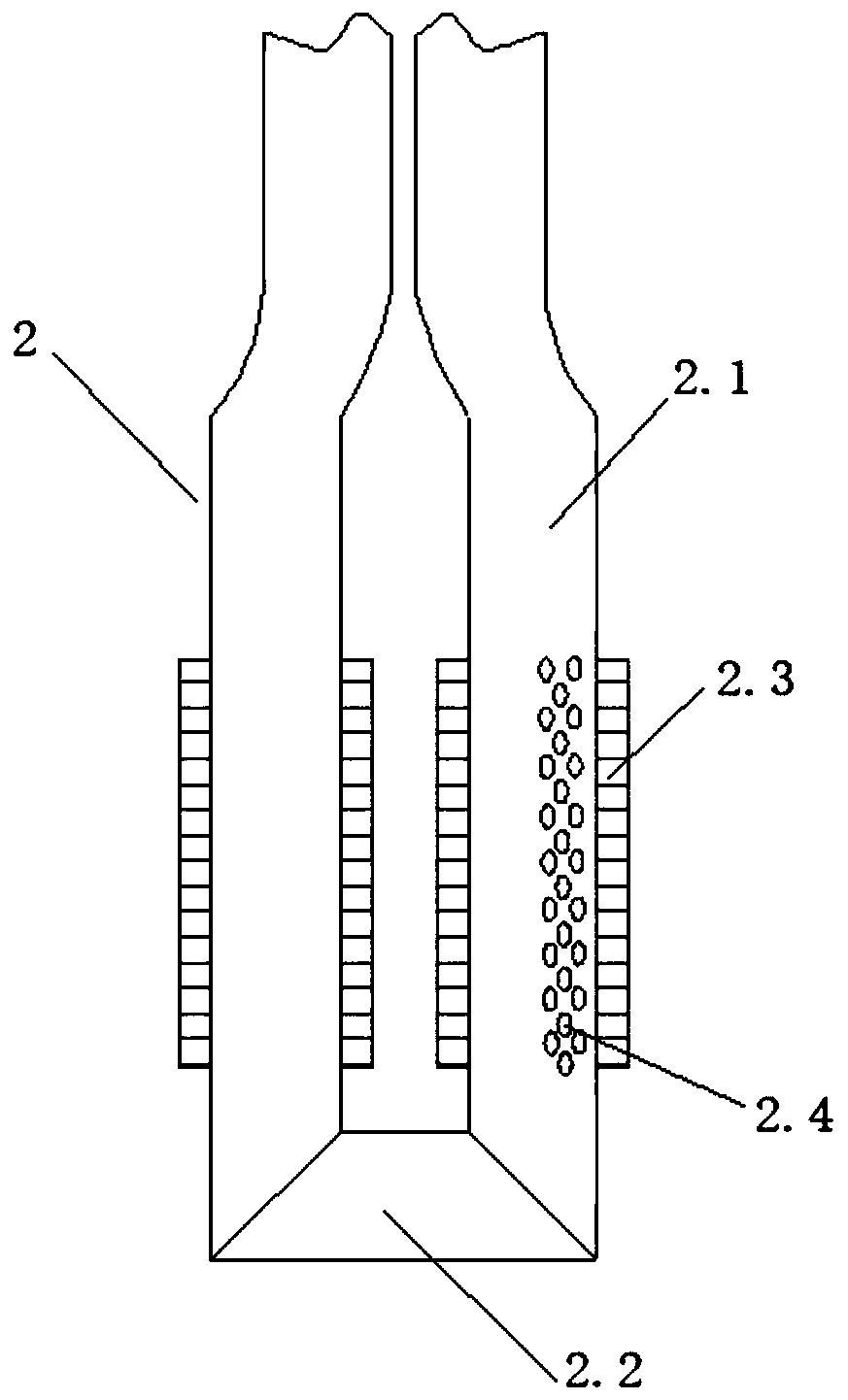

[0030] Such as figure 1 Shown is the open end cover of the automobile saddle of this embodiment, and the material is 40Cr. Such as figure 2 Shown is the induction hardened area of the inner surface of the open end cap of an automotive saddle.

[0031] The method for processing the opening end cover of the automobile saddle with the induction quenching and hardening of the inner ring surface in this embodiment includes the following steps: first, forging the 40Cr blank, and then performing quenching and tempering treatment on the blank, and the specific process of quenching and tempering is: heat preservation at 820°C 2h, water quenching, then high temperature tempering, tempering temperature 520°C, heat preservation 1.2h, the hardness of the blank after quenching and tempering is controlled at 28HRc, and then the blank is machined to obtain the opening end cover 1 of the automobile saddle, and then the automobile saddle The end cover 1 of the seat opening is strengthened ...

Embodiment 2

[0037] Such as figure 1 Shown is the open end cover of the automobile saddle of this embodiment, and the material is 42CrMo. Such as figure 2 Shown is the induction hardened area of the inner surface of the open end cap of an automotive saddle.

[0038] The method for processing the opening end cover of the automobile saddle with the induction quenching and hardening of the inner ring surface in this embodiment includes the following steps: first, forging the 42CrMo blank, and then performing quenching and tempering treatment on the blank, and the specific process of quenching and tempering is: heat preservation at 870°C 2h, water quenching, then high temperature tempering, tempering temperature 570°C, heat preservation 2h, the hardness of the blank after quenching and tempering is controlled at 33HRc, then the blank is machined to obtain the opening end cover 1 of the automobile saddle, and then the automobile saddle The open end cap 1 is strengthened by scanning inducti...

Embodiment 3

[0044] Such as figure 1 Shown is the open end cover of the automobile saddle of this embodiment, and the material is 40CrMo. Such as figure 2 Shown is the induction hardened area of the inner surface of the open end cap of an automotive saddle.

[0045] The method for processing the opening end cover of an automobile saddle with induction quenching and hardening on the inner ring surface of this embodiment includes the following steps: first, forging the 40CrMo blank, and then performing quenching and tempering treatment on the blank. The specific process of quenching and tempering is: heat preservation at 850°C 1.2h, water quenching, then high temperature tempering, tempering temperature 550°C, heat preservation 1.5h, the hardness of the blank after quenching and tempering is controlled at 30HRc, and then the blank is machined to obtain the automobile saddle opening end cover 1, and then the automobile saddle opening end cover 1 is obtained. The saddle opening end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com