Double-blowing molten iron desulfurization device

A hot metal desulfurization and injection device technology, applied in the field of hot metal treatment, can solve problems such as complex structure of hot metal desulfurization devices, inability to form high-efficiency complementarity, and accumulation of desulfurizing agents, so as to eliminate the accumulation of desulfurizing agents, improve dynamic conditions, and increase utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

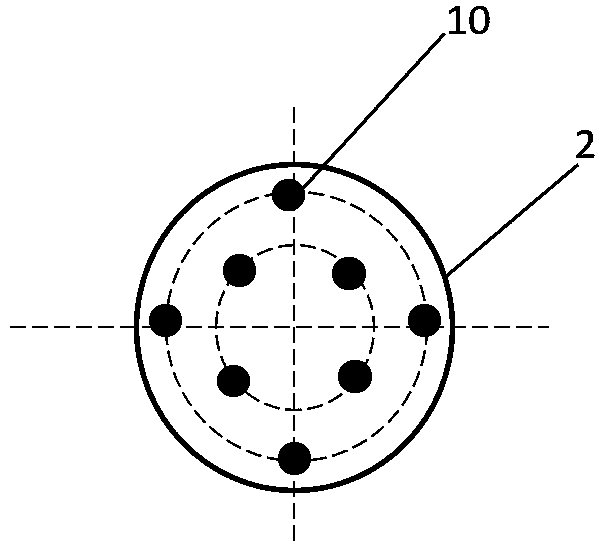

[0027] Such as figure 1 , a double-injection molten iron desulfurization device, including a desulfurization car and a molten iron tank 2 located above the desulfurization car; also includes a lifting stirring injection device. Described stirring injection device is positioned at the top of molten iron tank 2, comprises vertical stirring shaft 3 and the stirring blade 4 that is positioned at the lower end of stirring shaft 3; up and down between.

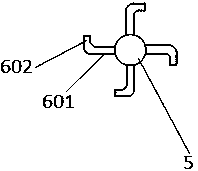

[0028] Such as image 3 , the agitating injection device also includes an air inlet pipe 5 and a plurality of horizontal L-shaped nozzles 6 . The stirring shaft 3 is provided with a cavity along the axial direction; the air inlet pipe 5 is inserted into the cavity of the stirring shaft 3 . The plurality of L-shaped nozzles 6 are symmetrically arranged on the outer periphery of the inlet pipe 5 along the center of the inlet pipe 5 , and are all located below the stirring blades 5 .

[0029] Each of the L-shaped nozzles 6 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com