Method for improving fermentation efficiency of lysine

A technology for lysine fermentation and lysine, applied in the field of amino acid fermentation, can solve the problems of low lysine efficiency, low added value of bacterial protein, high cost of lysine fermentation medium, etc., to facilitate subsequent enzymatic hydrolysis, Effect of increasing mass transfer rate, improving protein solubility and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Utilize the method for preparing lysine fermentation medium with bacterial protein, it comprises the steps:

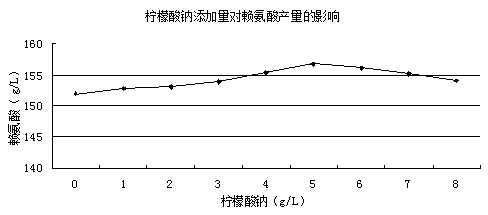

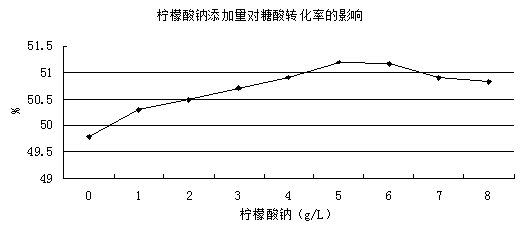

[0035] Take each raw material according to the following concentrations: bacterial protein distiller's grains joint hydrolyzate 200ml / L, glucose 40g / L, molasses 12g / L, ammonium sulfate 4g / L, sodium citrate 5g / L, potassium dihydrogen phosphate 10g / L, seven Magnesium sulfate water 0.8g / L, manganese sulfate tetrahydrate 0.02g / L, ferrous sulfate heptahydrate 0.02g / L, vitamin B 1 0.01g / L, biotin 0.5mg / L;

[0036]Add each raw material to water in turn, stir evenly, adjust the pH to 7.8 with 100g / L NaOH aqueous solution, and sterilize at 115°C for 10min to obtain the product.

[0037] The improvements of the fermentation medium of the present invention relative to the conventional medium mainly include:

[0038] Conventional medium: glucose 80g / L, corn steep liquor 10g / L, molasses 12g / L, ammonium sulfate 8g / L, potassium dihydrogen phosphate 10g / L, magnesium sulfate ...

Embodiment 2

[0049] Utilize the method for preparing lysine fermentation medium with bacterial protein, it comprises the steps:

[0050] Take each raw material according to the following concentrations: bacterial protein distiller's grains joint hydrolyzate 200ml / L, glucose 40g / L, molasses 12g / L, ammonium sulfate 4g / L, sodium citrate 5g / L, potassium dihydrogen phosphate 10g / L, seven Magnesium sulfate water 0.8g / L, manganese sulfate tetrahydrate 0.02g / L, ferrous sulfate heptahydrate 0.02g / L, vitamin B 1 0.01g / L, biotin 0.5mg / L;

[0051] Add each raw material to water in turn, stir evenly, adjust the pH to 7.8 with 100g / L NaOH aqueous solution, and sterilize at 115°C for 10min to obtain the product.

[0052] The preparation method of the cell protein distiller's grains joint hydrolyzate is as follows:

[0053] Grind and pulverize the bacterial protein, then add it to 8 times the weight of a 0.5M hydrochloric acid solution, stir evenly, then place it in a high-speed shearing machine at a s...

Embodiment 3

[0057] Utilize the technology of fermenting and producing lysine in fermentation medium, it comprises the steps:

[0058] The liquid volume in the 50L automatic fermentation tank is 30L fermentation medium, and the strain is Brevibacterium flavum XQ90; the Brevibacterium flavum is inserted into the fermentation medium according to the inoculation amount of 5%, the inoculation concentration is 2g / L, and the fermentation temperature is 0 -18h is 31°C, 18h-end is 34°C, the ventilation ratio is 1:0.7, the stirring speed is 300r / min, and the total fermentation time is 60h; during the fermentation process, the residual sugar content is maintained at 5 -10g / L, maintain ammonia nitrogen content at 1-2g / L by feeding 300g / L ammonium sulfate solution, feed ammonia water to control pH7.0-7.2, and feed defoamer to defoam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com