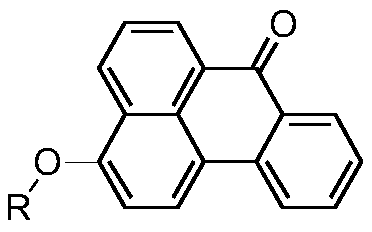

Preparation method and application of alkoxy benzanthrone photoinitiator

A technology of alkoxybenzoxanthrone light and bromobenzoxanthrone, which is applied in the field of photocuring synthesis, can solve problems such as poor compatibility, low crosslinking rate, and insufficient tensile strength of crosslinked materials, and achieve compatibility Improvement, high cross-linking efficiency, superior mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

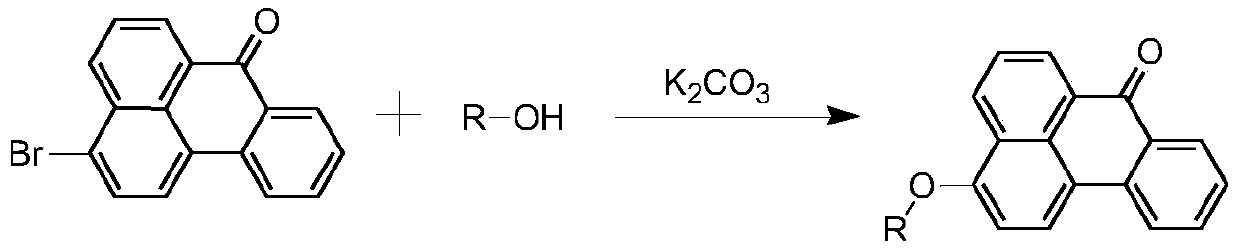

[0036] A preparation method of an alkoxybenzoxantrone photoinitiator, wherein the alkoxybenzoxantrone photoinitiator is mainly made of the following raw materials in parts by weight: 1 part of 3-bromobenzoxantrone, ethanol 4 parts, 2 parts of potassium carbonate, 10 parts of methylene chloride, 5 parts of water; including the following steps:

[0037] (1) Mix 3-bromobenzoxantrone, ethanol, and potassium carbonate according to the above parts by weight, stir evenly, heat up to 120°C, monitor by TLC (PE:EA=1:1), and after 5 hours, 3-bromobenzene After the reaction of the surrounding anthrone is complete, stop the reaction, cool to room temperature, add 5 parts of dichloromethane and the above parts by weight of water in sequence, stir for 20 minutes, then stand and separate to obtain the aqueous phase and the organic phase;

[0038] In this embodiment, 3-bromobenzothrone and alkyl alcohol carry out etherification reaction to synthesize alkoxybenzoxantrone. The equation is as fol...

Embodiment 2

[0052] A preparation method of an alkoxybenzoxanthone photoinitiator, the alkoxybenzoxanthrone photoinitiator is mainly made of the following raw materials in parts by weight: 1 part of 3-bromobenzoxanthrone, acetone 4 parts of alcohol, 2 parts of potassium carbonate, 10 parts of dichloromethane, 5 parts of water, comprising the following steps:

[0053] (1) Mix 3-bromobenzoxantrone, propanol and potassium carbonate according to the above parts by weight, stir evenly, heat up to 125°C, monitor by TLC (PE:EA=1:1), after 6 hours, 3-bromobenzene After the reaction of the surrounding anthrone is complete, stop the reaction, cool to room temperature, add 5 parts of dichloromethane and the above-mentioned parts by weight of water in sequence, stir for 25 minutes, then stand and separate to obtain the aqueous phase and the organic phase;

[0054] (2) The aqueous phase was extracted with another 5 parts of dichloromethane, the combined organic phases were dried with anhydrous sodium s...

Embodiment 3

[0059] A preparation method of an alkoxybenzoxantrone photoinitiator, wherein the alkoxybenzoxantrone photoinitiator is mainly made of the following raw materials in parts by weight: 1 part of 3-bromobenzoxantrone, butyl 4 parts of alcohol, 2 parts of potassium carbonate, 10 parts of dichloromethane, 5 parts of water, comprising the following steps:

[0060] (1) Mix 3-bromobenzoxantrone, ethanol, and potassium carbonate according to the above parts by weight, stir evenly, heat up to 120°C, monitor by TLC (PE:EA=1:1), and after 6 hours, 3-bromobenzene After the reaction of the surrounding anthrone is complete, stop the reaction, cool to room temperature, add 5 parts of dichloromethane and the above parts by weight of water in sequence, stir for 30 minutes, then stand and separate to obtain the aqueous phase and the organic phase;

[0061] (3) The aqueous phase was extracted with another 5 parts of dichloromethane, the combined organic phases were dried over anhydrous sodium sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com