Preparation method of uralipide

A technology of ularitide and peptide resin, which is applied in the field of polypeptide drug preparation, can solve the problems of inability to bring about clinical prognosis, achieve the effects of shortening the preparation process cycle, wide practical value and application prospect, and improving product purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The synthesis of embodiment 1 ularitide resin

[0035] Ularitide peptide resin is:

[0036] Boc-Thr(tBu)-Ala-Pro-Arg(Pbf)-Ser(tBu) 5 -Leu-Arg(Pbf)-Arg(Pbf)-Ser(tBu)-Ser(tBu)10 -Cys(Trt)-Phe-Gly-Gly-Arg(Pbf) 15 -Met-Asp(OtBu)-Arg(Pbf)-Ile-Gly 20 -Ala-Gln(Trt)-Ser(tBu)-Gly-Leu 25 -Gly-Cys(Trt)-Asn(Trt)-Ser(tBu)-Phe 30 -Arg(Pbf)-Tyr(tBu)-resin

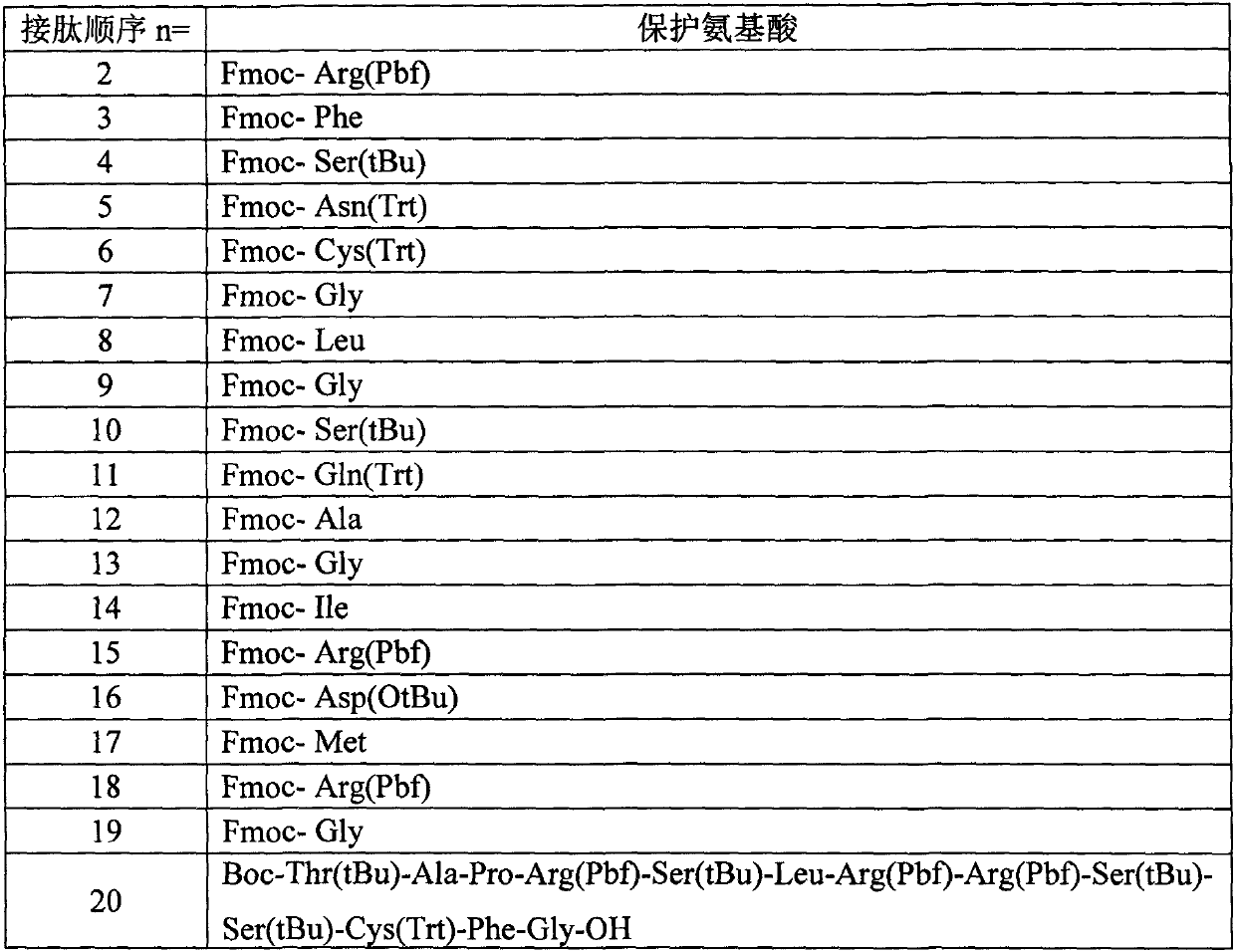

[0037] Using Fmoc-Gly-resin as the starting resin, Fmoc deprotection and coupling reactions were performed, followed by coupling with the protected amino acids shown in Table 2 to prepare ularitide resin. The protected amino acids or fragments corresponding to the protected amino acids used in this example are shown in the table below:

[0038] Table 2

[0039]

[0040] 1. Access to the second protected amino acid

[0041] Take 0.09 mol of the second protected amino acid and 0.09 mol of HOBt, and dissolve it with an appropriate amount of DMF; take another 0.09 mol of DIC, slowly add it to the protected amino acid DMF sol...

Embodiment 2

[0046] Example 2 Preparation of Ularitide Crude Product

[0047] Get the Liularitide resin obtained in Example 1, add a cleaving reagent (cracking reagent 10mL / gram resin) with a volume ratio of TFA:water:EDT=95:5:5, stir evenly, stir at room temperature for 3 hours, and react The mixture was filtered with a sand core funnel, the filtrate was collected, the resin was washed 3 times with a small amount of TFA, the combined filtrates were concentrated under reduced pressure, anhydrous diethyl ether was added to precipitate, and anhydrous diethyl ether was used to wash the precipitate 3 times, and dried under reduced pressure at 35-45°C to obtain Off-white powder.

[0048] The obtained off-white powder was dissolved in 30% acetic acid solution to make a solution of about 3 mg / ml, and a saturated solution of iodine / ethanol was added dropwise with stirring until complete cyclization, and concentrated under reduced pressure at 35-40°C to obtain a concentrated solution of atosiban cr...

Embodiment 3

[0049] Example 3 Purification of Ularitide Crude Product

[0050] Take the crude ularitide obtained in Example 2, add water and stir, adjust the pH to 8.5 with ammonia water until completely dissolved, filter the solution with a 0.45 μm mixed microporous membrane, and purify it for later use;

[0051] High-performance liquid chromatography was used for purification, and the chromatographic filler for purification was 10 μm reversed-phase C18. Two mobile phase systems were used for purification alternately. The first mobile phase system was 0.1% TFA / water solution-0.1% TFA / acetonitrile solution, and the second mobile phase system was 0.1% TFA / water solution-0.1% TFA / acetonitrile solution. The two mobile phase systems are 50mmol ammonium acetate / water solution-acetonitrile. The flow rate of the 77mm*250mm chromatographic column is 90mL / min, the gradient system is used for elution, and the sample is injected and purified in a circular manner. The crude product solution is loaded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com