A kind of synthetic technique of carbasalate calcium

A technology of carbasalate calcium and synthesis process is applied in the synthesis process of carbasalate calcium and the preparation field of organic medicines, and can solve the problems of high production cost, high price and the like, and achieves reduction in raw material cost, improvement in yield, and simplification of production. The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

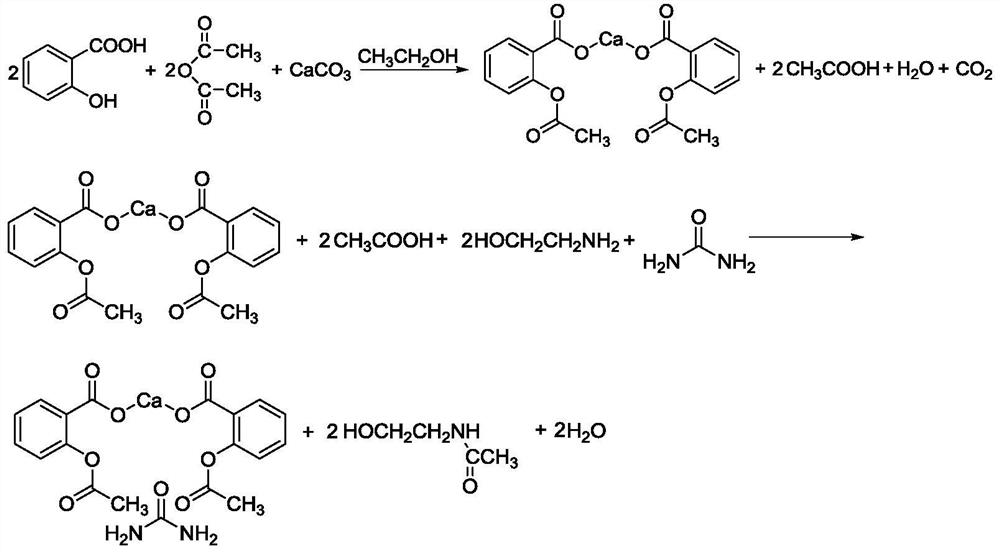

Method used

Image

Examples

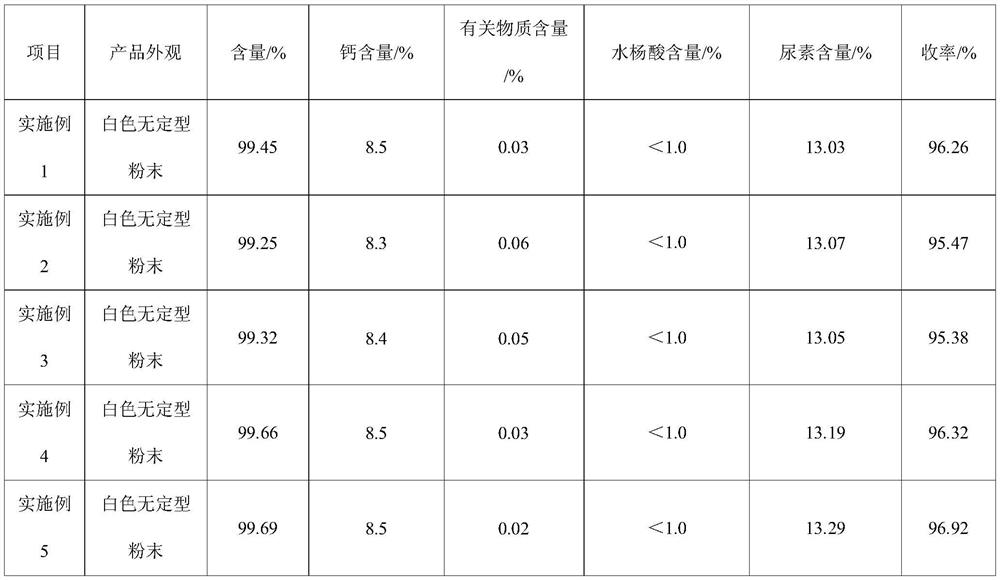

Embodiment 1

[0031]In a 2L three-mouth flask with reflux condensing tube and stirring, 180g ethanol, 276.24g (2mol) of salicylic acid, 204.18g (2mol) of acetic anhydride were added sequentially, stirred, and 100.09g (1mol) of calcium carbonate was added in batches (the calcium carbonate was divided, added once every 10min, and each addition amount was 1.5 times the previous addition amount, added within 2 hours, the addition amount was 0.26g, 0.39g, 0.58g, 0.87g, 1.3 g ..., until the addition is completed), heat up to 60 °C, keep warm for 0.5 h, cool down to 25 °C. Then add ethanolamine 122.16g (2mol), pure water 330.33g, urea 66.07g (1.1mol, water to urea mass ratio of 10:2), reaction time 1h, after the end of the reaction cooled to 15 °C, centrifugation, 50g ethanol leaching, drying, to obtain high-quality carbapiplin calcium.

Embodiment 2

[0033] In a 2L three-mouth flask with reflux condensing tube and stirring, 180g of ethanol, 276.24g of salicylic acid, and 204.18g of acetic anhydride were added sequentially, stirred, and 100.09g of calcium carbonate was added in batches (the calcium carbonate was divided into parts, added every 15min, and each addition amount was 1.5 times the amount of the previous addition, added within 2.5h), heated to 65 °C, kept warm for 1h, and cooled to 30 °C. Then add ethanolamine 122.16g, pure water 330.33g, urea 66.07g (water and urea mass ratio of 10:2), reaction time 2h, after the end of the reaction cooled to 20 °C, centrifugation, 50g ethanol leaching, drying, to obtain high-quality carbapipillin calcium.

Embodiment 3

[0035] In a 2L three-mouth flask with reflux condensing tube and stirring, 180g of ethanol, 276.24g of salicylic acid, and 204.18g of acetic anhydride were added sequentially, stirred, and 100.09g of calcium carbonate was added in batches (the calcium carbonate was divided into parts, added every 20min, and each addition amount was 1.5 times the previous addition amount, added within 3h), heated to 60 °C, insulation 0.5h, cooled to 30 °C. Then add ethanolamine 122.16g, pure water 360g, urea 66.07g, reaction time 3h, after the end of the reaction cooled to 15 °C, centrifugation, 50g ethanol leaching, drying, to obtain high-quality carbapiprin calcium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com