Method for treating organic wastewater by activating peroxymonosulfate with functionalized zirconium-based metal organic framework/protonated carbon nitride composite material

An organic framework and composite material technology, applied in organic compound/hydride/coordination complex catalysts, special compound water treatment, oxidized water/sewage treatment, etc., can solve the problem that the photocatalytic ability of the composite has not been greatly improved , Not suitable for waste water pollutants, the water solution is not easy to disperse and other problems, to achieve the effect of wide application, high treatment effect and rapid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

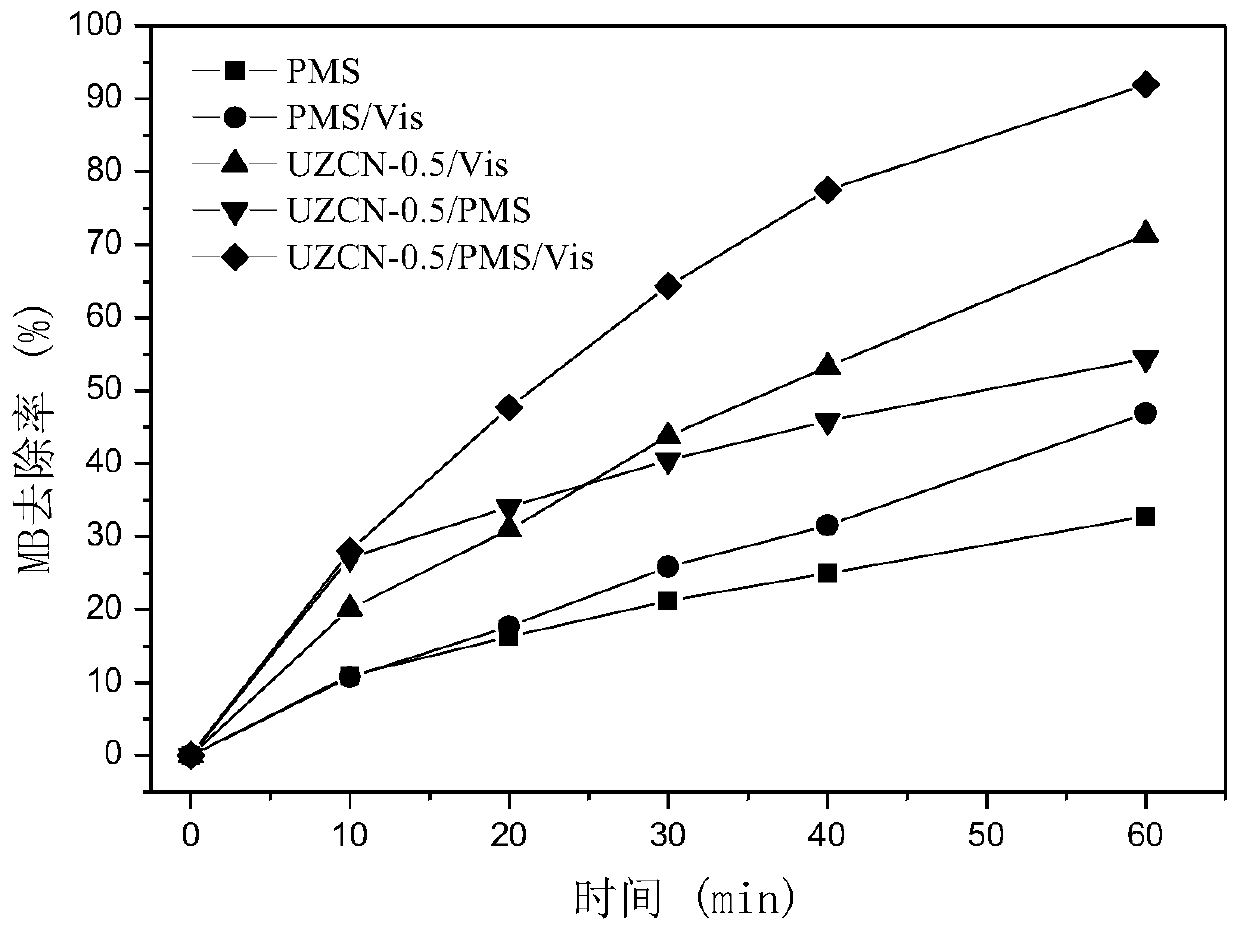

[0036] A method for activating peroxymonosulfate with a functionalized zirconium-based metal-organic framework / protonated carbon nitride composite material for treating organic wastewater, specifically using a functionalized zirconium-based metal-organic framework / protonated carbon nitride composite material to activate peroxymonosulfuric acid Salt treatment treats methylene blue wastewater, including the following steps:

[0037] Weigh functionalized zirconium-based metal-organic framework / protonated carbon nitride composites (UZCN-0.2, UZCN-0.5, UZCN-1, UZCN-3, UZCN-5, UZCN-8, UZCN-10, UZCN-20) , each 25mg, respectively added to 50mL methylene blue solution with a concentration of 20mg / L (the pH value of the solution is 7.1), stirred with a magnetic stirrer at a speed of 600r / min, dark reaction for 1h, and added 15mg of peroxymonosulfuric acid Potassium hydrogen (PMS) was irradiated by a 150W high-pressure xenon lamp at a temperature of 30°C for a photocatalytic reaction for...

Embodiment 2

[0077] A method for activating peroxymonosulfate with a functionalized zirconium-based metal-organic framework / protonated carbon nitride composite material for treating organic wastewater, specifically using a functionalized zirconium-based metal-organic framework / protonated carbon nitride composite material to activate peroxymonosulfuric acid Salt treatment treats methylene blue wastewater, including the following steps:

[0078] Weigh 5 parts of the functionalized zirconium-based metal-organic framework / protonated carbon nitride composite material (UZCN-0.5) prepared in Example 1, each 25 mg, add 50 mL of methylene blue solution with a concentration of 20 mg / L (the The pH value of the solution is 7.1), stir with a magnetic stirrer under the condition of rotating speed 600r / min, add 5mg, 15mg, 25mg, 35mg, 50mg potassium hydrogen persulfate (PMS) respectively, the hydrogen persulfate in the reaction system The amount of potassium added is 0.1g / L, 0.3g / L, 0.5g / L, 0.7g / L, 1g / L i...

Embodiment 3

[0082] A method for activating peroxymonosulfate with a functionalized zirconium-based metal-organic framework / protonated carbon nitride composite material for treating organic wastewater, specifically using a functionalized zirconium-based metal-organic framework / protonated carbon nitride composite material to activate peroxymonosulfuric acid Salt treatment treats methylene blue wastewater, including the following steps:

[0083] Weigh 5 parts of the functionalized zirconium-based metal-organic framework / protonated carbon nitride composite (UZCN-0.5) prepared in Example 1. , concentration is 20mg / L in the methylene blue solution (the pH value of this solution is 7.1), stir under the condition of rotating speed 600r / min with magnetic stirrer, add 25mg potassium hydrogen persulfate (PMS) respectively, in each reaction system The addition amount of potassium peroxymonosulfate was 0.5g / L, and the photocatalytic reaction was carried out for 60min under the irradiation of a 150W hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com