Aircraft anti-icing composite material and preparation method thereof

A composite material and deicing technology, applied in the field of aviation chemistry, can solve the problems of poor performance of deicing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The anodized aluminum single-pass porous material with a pore diameter of 40nm, a pore depth of 30um, and a pore spacing of 300nm is adhered to an aluminum plate with the same area and a thickness of 2mm, with the side with holes facing up. Adhere N55 NdFeB magnets of the same area under the aluminum plate, and then suspend the magnetic particles into 5-10nm spherical iron tetroxide, and dissolve them in the base liquid after surface treatment with sodium oleate to obtain the magnetic fluid. The base liquid is mainly composed of weight The percentage is 80% of paraffin oil and 20% by weight of Grade III clean environment-friendly aviation kerosene, which can be purchased on the market. The magnetic fluid is added to the surface of the anodized aluminum single-pass porous material until it does not overflow from the surface of the anodized aluminum single-pass porous material, and the anti-icing composite material is obtained.

[0035] Such as figure 1 Shown is the SEM ...

Embodiment 2

[0038] The anodized aluminum single-pass porous material with a pore diameter of 200nm, a pore depth of 80um, and a pore spacing of 500nm was adhered to a polymethyl methacrylate plate with the same area and a thickness of 4mm, with the side with holes facing up. Adhere EP-B type NdFeB magnets of the same area under the aluminum plate, and then make the suspended magnetic particles into 10-20nm spherical iron tetroxide, and after surface treatment with PEG2000, dissolve them in the base liquid to obtain the magnetic fluid. It is added to the surface of the anodized aluminum single-pass porous material until it does not overflow from the surface of the anodized aluminum single-pass porous material, and the anti-icing composite material is obtained.

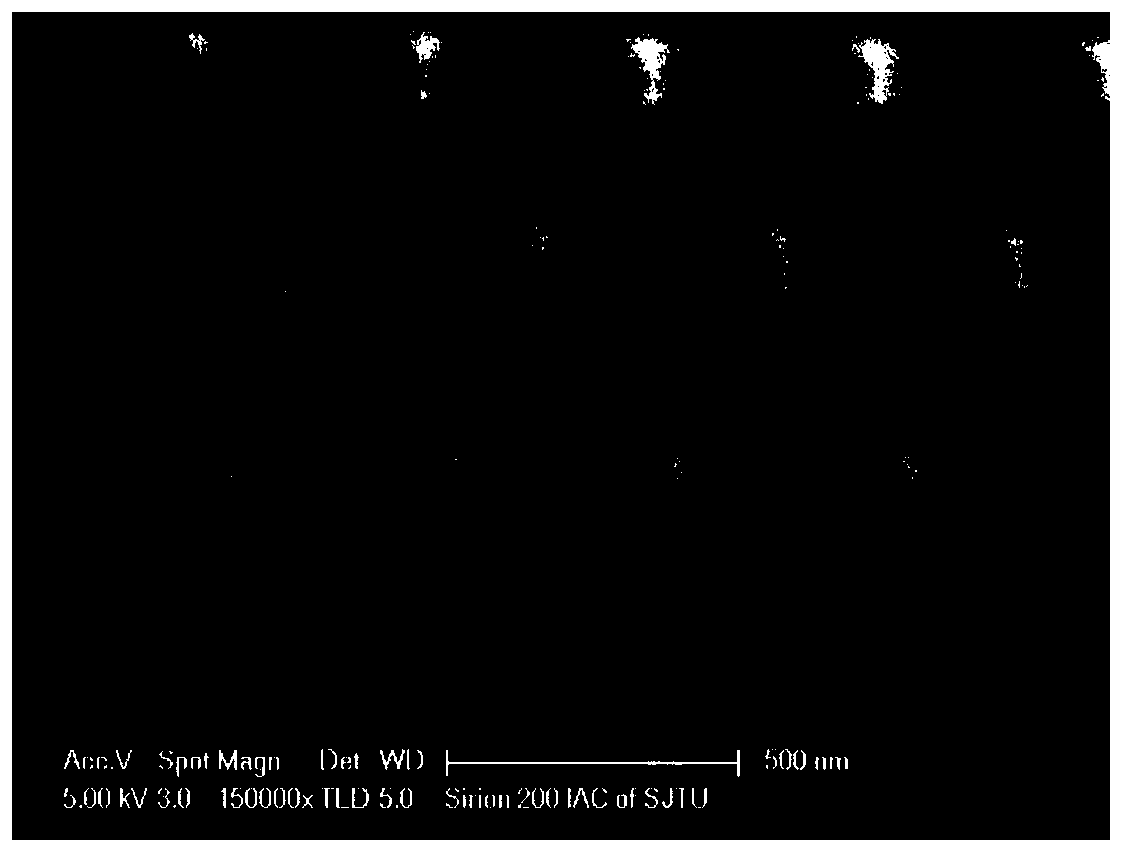

[0039] Such as image 3 Shown is the SEM image of the anodized aluminum single-pass porous material.

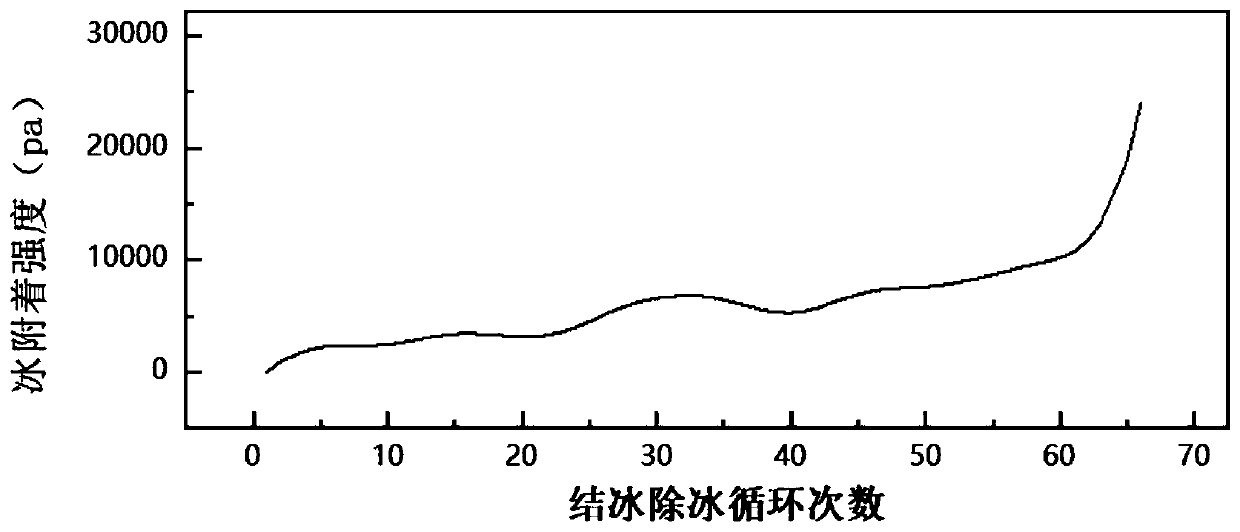

[0040] The anti-icing performance of the composite material is evaluated by the ice adhesion test. The dynamometer is Sandu SH-...

Embodiment 3

[0042]The anodized aluminum single-pass porous material with a pore diameter of 100nm, a pore depth of 60um, and a pore spacing of 400nm was adhered to a polymethyl methacrylate plate with the same area and a thickness of 3mm, with the side with holes facing up. Adhere a samarium-cobalt permanent magnet of the same area under the aluminum plate, and then make the suspended magnetic particles 15-20nm spherical ferric oxide, which is surface-treated with polyethylene glycol (PEG2000) with an average molecular weight of 2000, and then dissolved in the base liquid The magnetic fluid is obtained, and the magnetic fluid is added to the surface of the anodized aluminum single-pass porous material until it does not overflow from the surface of the anodized aluminum single-pass porous material, and the anti-icing composite material is obtained.

[0043] Such as Figure 5 As shown, the anti-icing performance of the composite material is evaluated by the ice adhesion test, the dynamomete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com