Method for processing V-type groove of ultra-thick metal substrate printed board

A metal substrate and processing method technology, applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of inability to process, shortened life, and short life, and achieve the effect of fast and safe production and improved life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

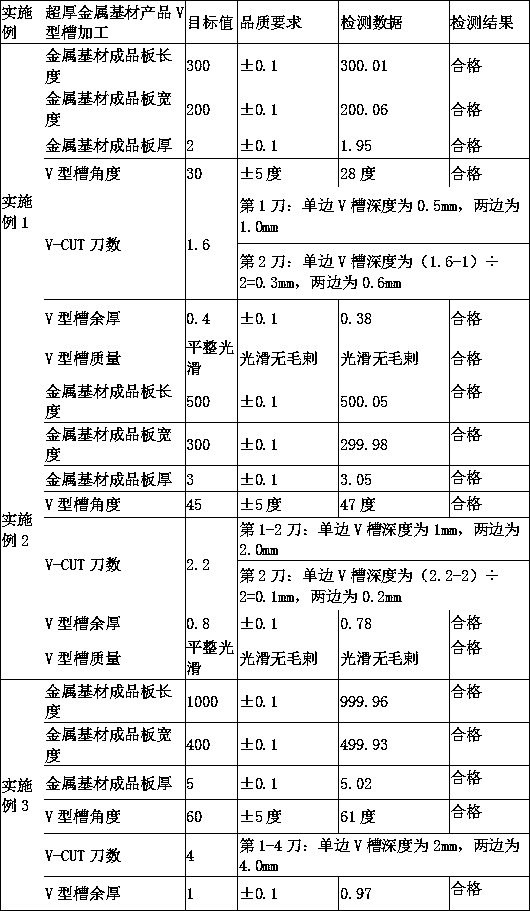

Embodiment 1

[0028] A method for processing a V-groove of an ultra-thick metal substrate printed board, characterized in that it comprises the following steps:

[0029] S1. Selection of V-CUT machine and V-CUT knife: Choose a PIN nail V-CUT machine with the function of controlling the depth of V-cut, and choose a V-CUT tool with the same degree according to the V-CUT angle required for processing;

[0030] S2. Design of V-CUT processing data: According to the equipment parameters of the V-CUT machine, set the hanging hole according to the hole center distance of 100mm, and calculate the center line of the V-CUT knife passing through according to the outer frame data and degree data processed as required, and make the data;

[0031] S3. V-CUT processing parameter setting: processing times: design the V-CUT times according to the thickness of the PCB and the excess thickness to be processed, where, the V-CUT times (integer) = ((board thickness - excess thickness) ÷ processing depth / knife) ...

Embodiment 2

[0039] A method for processing a V-groove of an ultra-thick metal substrate printed board, characterized in that it comprises the following steps:

[0040] S1. Selection of V-CUT machine and V-CUT knife: Choose a PIN nail V-CUT machine with the function of controlling the depth of V-cut, and choose a V-CUT tool with the same degree according to the V-CUT angle required for processing;

[0041] S2. Design of V-CUT processing data: According to the equipment parameters of the V-CUT machine, set the hanging hole according to the hole center distance of 80mm, and calculate the center line of the V-CUT knife passing through according to the outer frame data and degree data processed as required, and make the data;

[0042]S3. V-CUT processing parameter setting: processing times: design the V-CUT times according to the thickness of the PCB and the excess thickness to be processed, where, the V-CUT times (integer) = ((board thickness - excess thickness) ÷ processing depth / knife) ÷ ...

Embodiment 3

[0050] A method for processing a V-groove of an ultra-thick metal substrate printed board, characterized in that it comprises the following steps:

[0051] S1. Selection of V-CUT machine and V-CUT knife: Choose a V-CUT machine with a V-CUT machine with the function of controlling the depth of V-cut, and choose a V-CUT tool with the same degree according to the V-CUT angle required for processing;

[0052] S2. Design of V-CUT processing data: According to the equipment parameters of the V-CUT machine, set the hanging hole according to the hole center distance of 120mm, and calculate the center line of the V-CUT knife according to the outer frame data and degree data processed as required and make the data;

[0053] S3. V-CUT processing parameter setting: processing times: design the V-CUT times according to the thickness of the PCB and the excess thickness to be processed, where, the V-CUT times (integer) = ((board thickness - excess thickness) ÷ processing depth / knife) ÷ 2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com