Foam fluid performance and defoaming separation effect test experimental apparatus and method

A foam fluid and experimental device technology, applied in the direction of measuring devices, liquid dispersion analysis, particle and sedimentation analysis, etc., can solve the problems of no quantitative solution, single measurement method, etc., and achieve reduction of carrying capacity, optimization of defoaming components, and defoaming The effect of separation effect assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

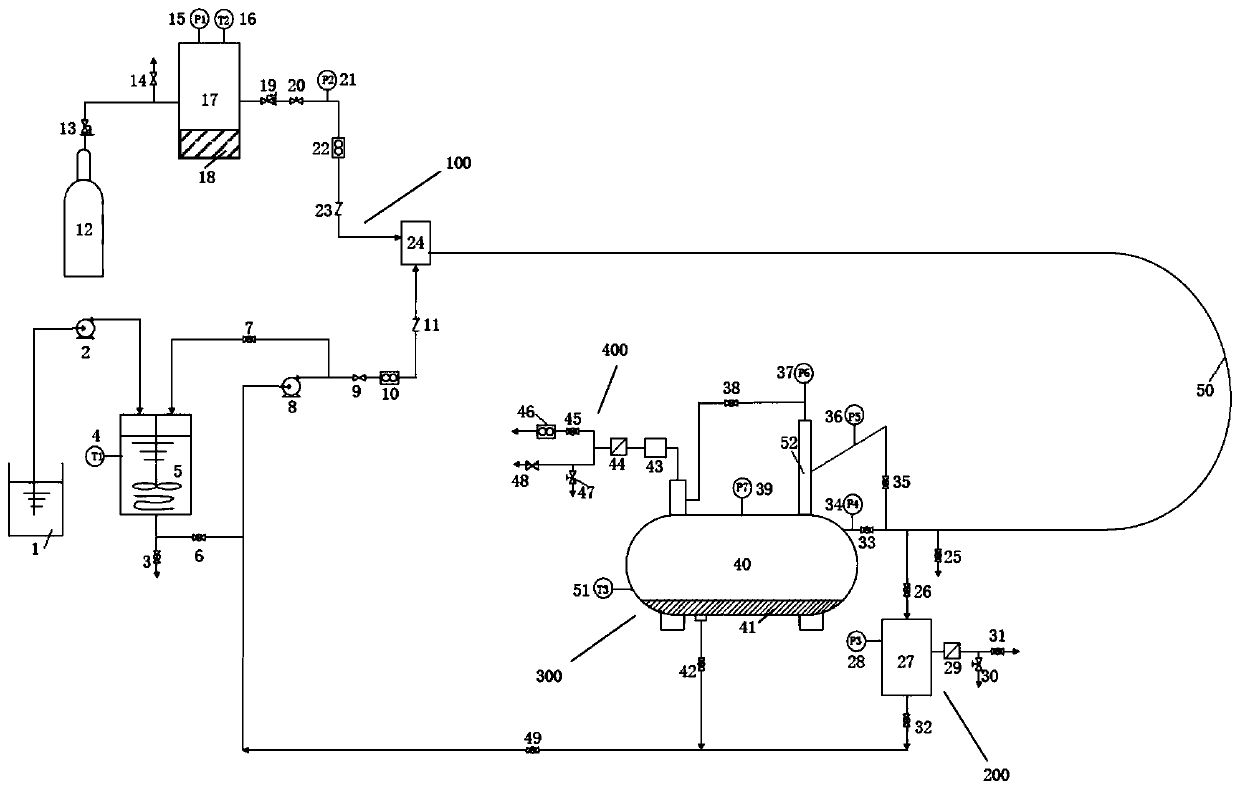

[0043] The disclosure provides an experimental device for testing foam fluid performance and defoaming separation effect, which is used for testing and evaluating CO 2 Foam performance and defoaming separation effect of flooding and production fluid in gathering, transportation and separation. The experimental device includes a foam generation module 100 for generating foam fluid, and an experimental ring for transporting foam fluid and making foam fluid fully develop in the loop. Road 50, the foam performance testing module 200 for testing the foam fluid performance, the foam separation processing module 300 for foam and fluid, gas separation and the defoaming result evaluation module 400 for testing and evaluating the defoaming result, detailed description here :

[0044] Foam generating module 100, generating foam fluid for simulating real work under CO 2 The foam fluid produced after being mixed with the oil layer in a certain proportion, the foam generation module 100 in...

Embodiment 2

[0059] The foam separation processing module 300 of the present disclosure adopts the second technical scheme, which adds a column type cyclone separator 52 on the basis of embodiment 1, and the column type cyclone separator 52 is installed on the upper end of the horizontal separator 40, The main pipeline at the end of the experimental loop 50 is provided with three bypass pipelines, and according to the flow direction of the foam fluid in the experimental loop 50, they are the first bypass pipeline, the second bypass pipeline, and the third bypass pipeline. pipeline, the third bypass pipeline is connected to the column type cyclone separator 52 in the foam separation treatment module 300, the sixteenth valve 35 is installed on the third bypass pipeline, and the sixteenth valve 35 is connected with the column type cyclone separator The fifth pressure sensor 36 is installed on the third bypass pipeline between the separators 52, the sixteenth valve 35 is opened, and the foam fl...

Embodiment 3

[0064] The present disclosure provides an experimental method for testing foam fluid performance and defoaming separation effect. The experimental device disclosed in Embodiment 1 of the present disclosure is used for measurement. The experimental operation process is as follows:

[0065] The first step: the preparation stage: the CO 2 CO in cylinder 2 The gas is delivered to the gas storage tank 17, CO 2 The gas is passed into the entire experimental device from the gas storage tank 17, the impurities in the pipe are removed, and the valve opening state of the horizontal separator 40 is adjusted, wherein the gas phase outlet of the horizontal separator 40 is opened, and the liquid phase outlet of the horizontal separator 40 is closed. .

[0066] Second step: generate foam fluid stage: adjust the eighth valve 19, CO 2 Gas adjustment to desired gas flow, CO 2 The gas is passed into the foam generator 24, and the second ball valve 6 at the lower end of the oil-water mixing k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com