Multifunctional energy-saving biomass semi-gasification furnace capable of preventing ash accumulation

A multi-functional, biomass technology, which is applied to stoves/stoves with hot water devices, household stoves/stoves, household heating, etc., can solve the problems of flue gas waste heat, soot accumulation, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

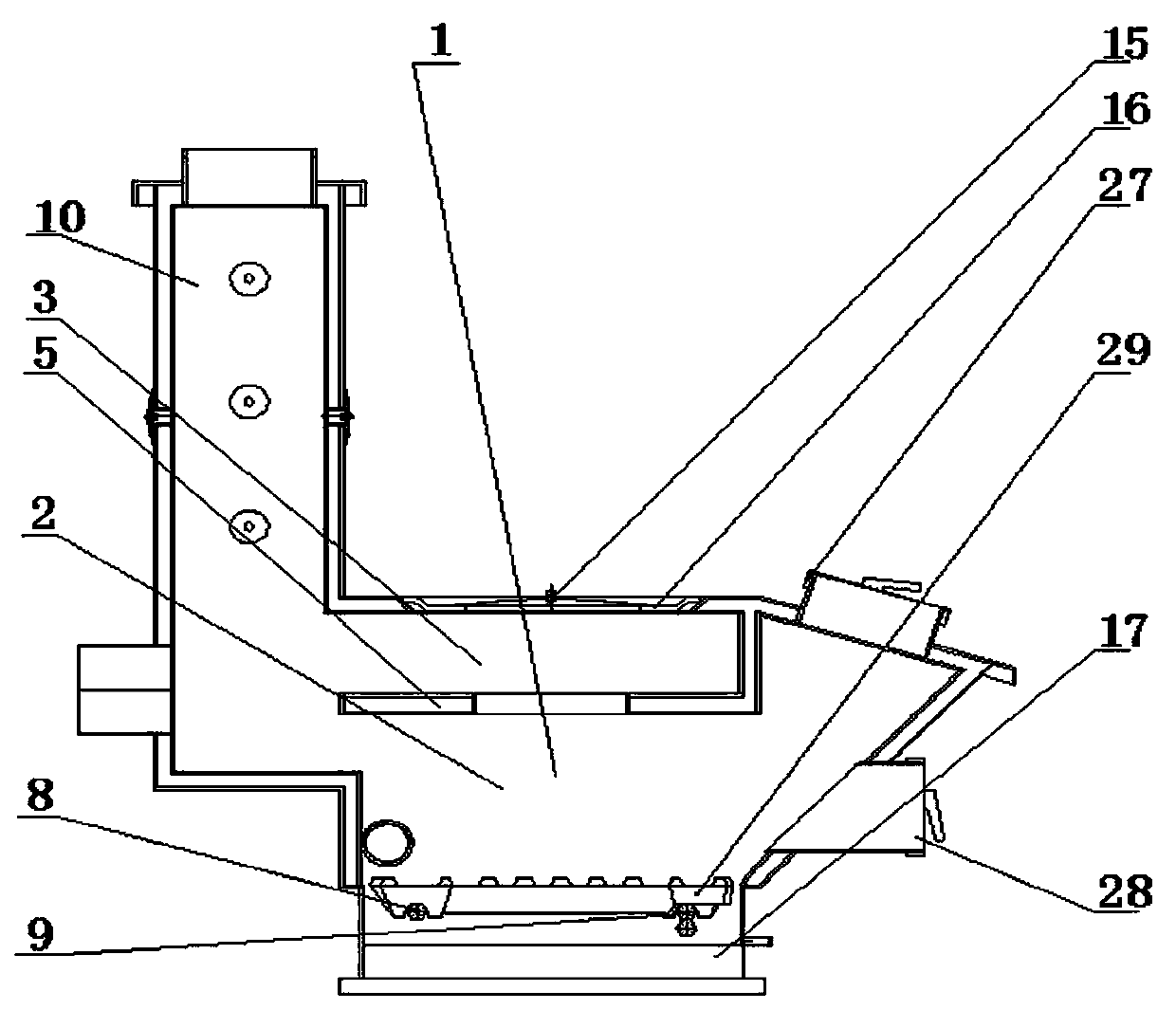

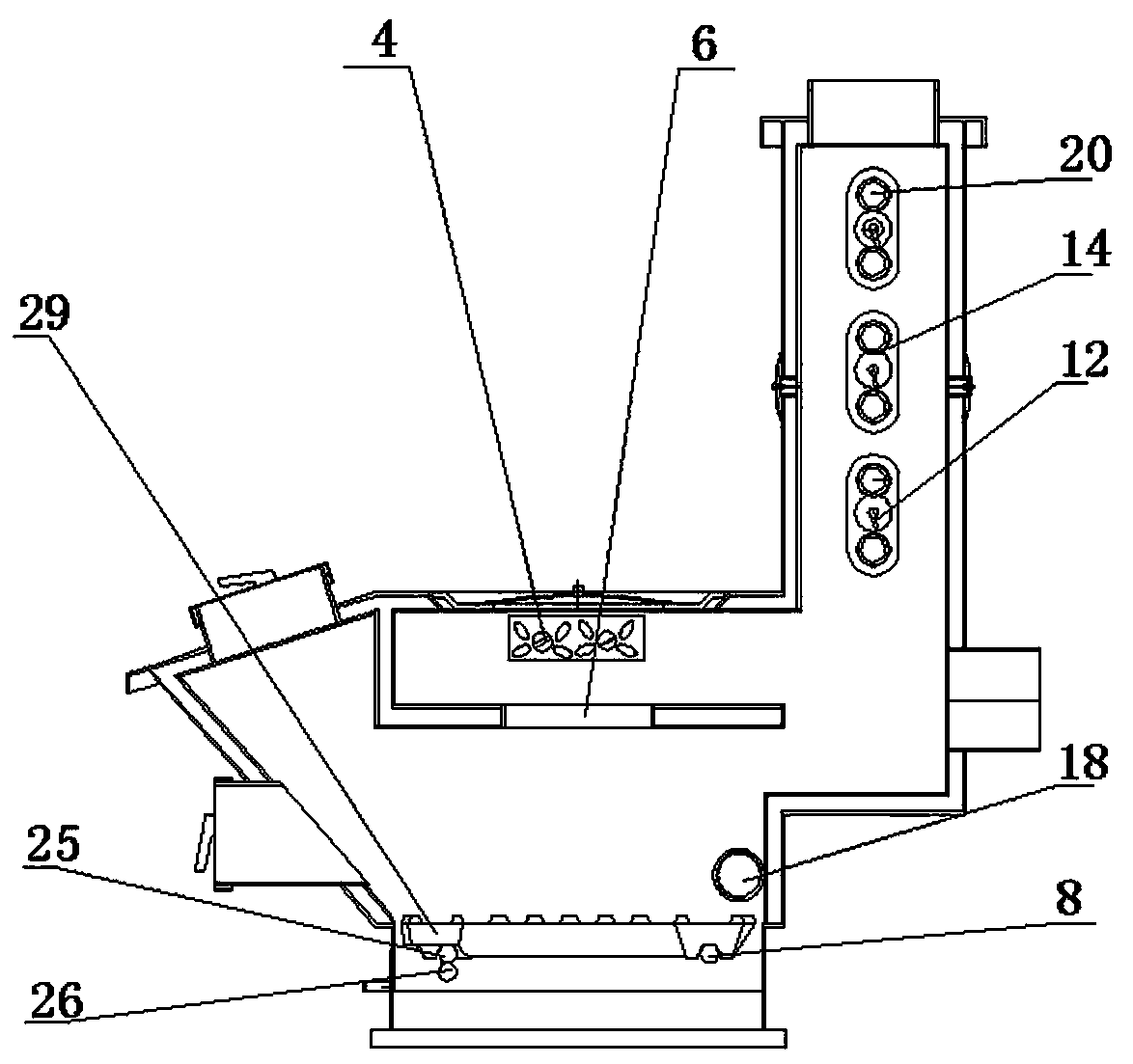

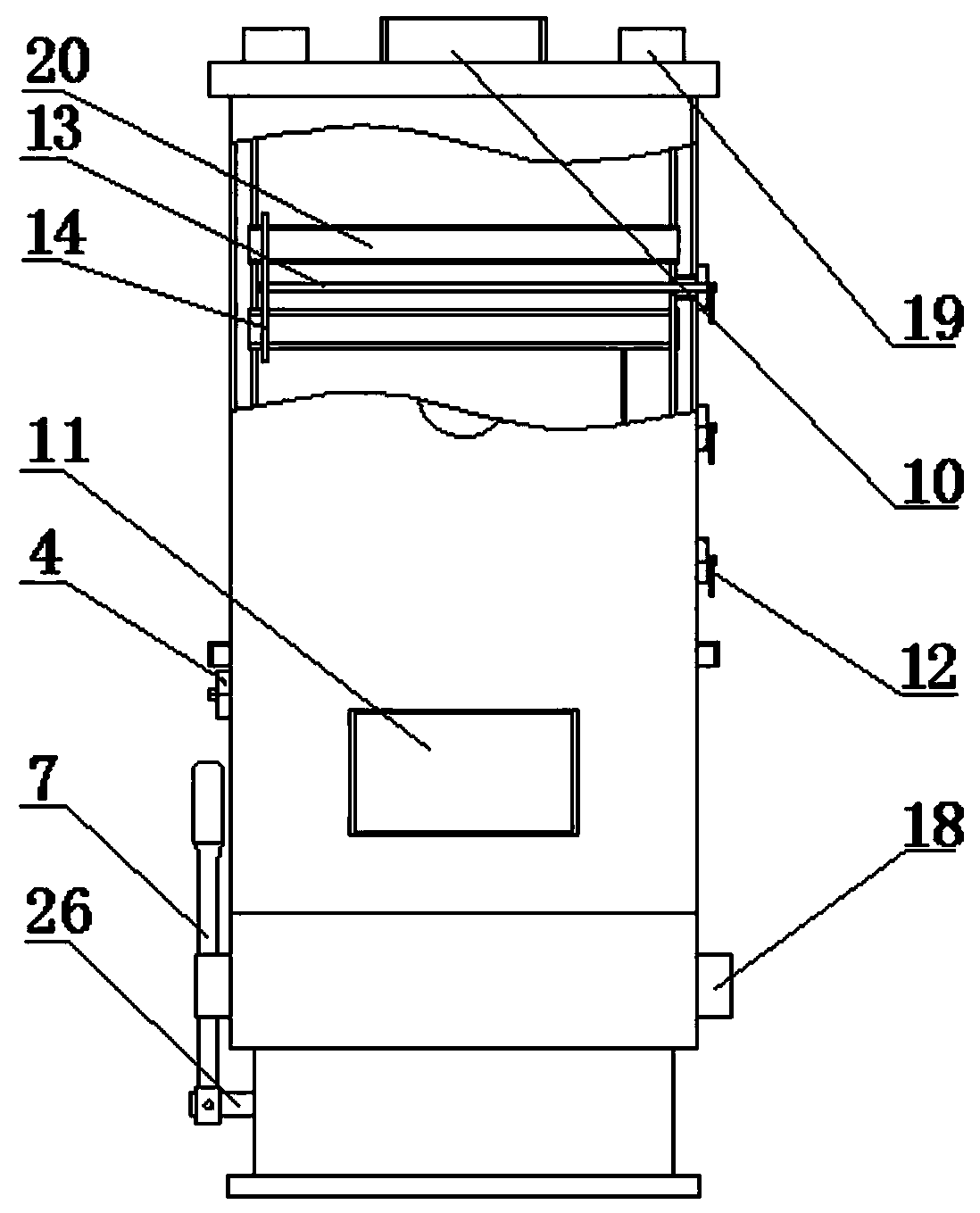

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a multi-functional energy-saving biomass semi-gasification furnace for preventing soot accumulation, including a boiler body 1, a first-floor combustion chamber 2, a second-floor combustion chamber 3, a secondary air damper 4, a grate group 29, and a furnace water-cooled Plate 5, smoke hole 6, grate adjustable wrench 7, fixed shaft 8, movable shaft group 9, main smoke outlet channel 10, furnace door, auxiliary flue 11, pull ring 12, pull rod 13, pull plate 14, furnace cover 15. Furnace ring 16, ash hopper 17, water inlet pipe 18, water outlet pipe 19, heating pipe 20, the combustion chamber 2 of the first layer is arranged at the bottom of the boiler main body 1, and the water cooling plate 5 of the furnace is arranged on the first layer of combustion chamber Above the chamber 2, the middle part of the furnace water cooling plate 5 is provided with a circu...

Embodiment 2

[0030] Such as figure 1 , figure 2 , Figure 7 As shown, the ash receiving hopper 17 is arranged under the grate group 29 and is located at the bottom of the boiler body 1, the furnace ring 16 is arranged on the top of the second-story combustion chamber 3, and the center of the furnace ring 16 is provided with a furnace Cover 15.

Embodiment 3

[0032] Such as figure 1 , figure 2 , image 3 As shown, the left side of the main smoke outlet channel 10 is provided with an auxiliary flue 11, one end of the auxiliary flue 11 communicates with the combustion chamber 2 on the first floor and the combustion chamber 3 on the second floor, and one end extends out of the boiler body 1. The heating tubes 20 are arranged in parallel inside the main smoke outlet channel 10, the number of the heating tubes 20 is six, the pull rings 12 are arranged in parallel at one end outside the main smoke outlet channel 10, and the pull rings 12 The number is 3, one end of the pull rod 13 extends out of the main smoke outlet channel 10 and is connected with the pull ring 12 by a pin, and one end is welded to the pull plate 14 inside the main smoke outlet channel 10, and the pull plate 14 is semi-elliptical shape, the upper and lower ends of the pull plate 14 are provided with through holes in parallel, the size of the through holes matches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com