Oxygen combustion-supporting system for grate-type garbage incinerator

A technology of waste incinerator and combustion-supporting system, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of poor waste burnout rate, increase waste incineration cost, and change calorific value, etc., to improve combustion intensity and combustion. The effect of speed, shortening the ignition time, and stabilizing combustion in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

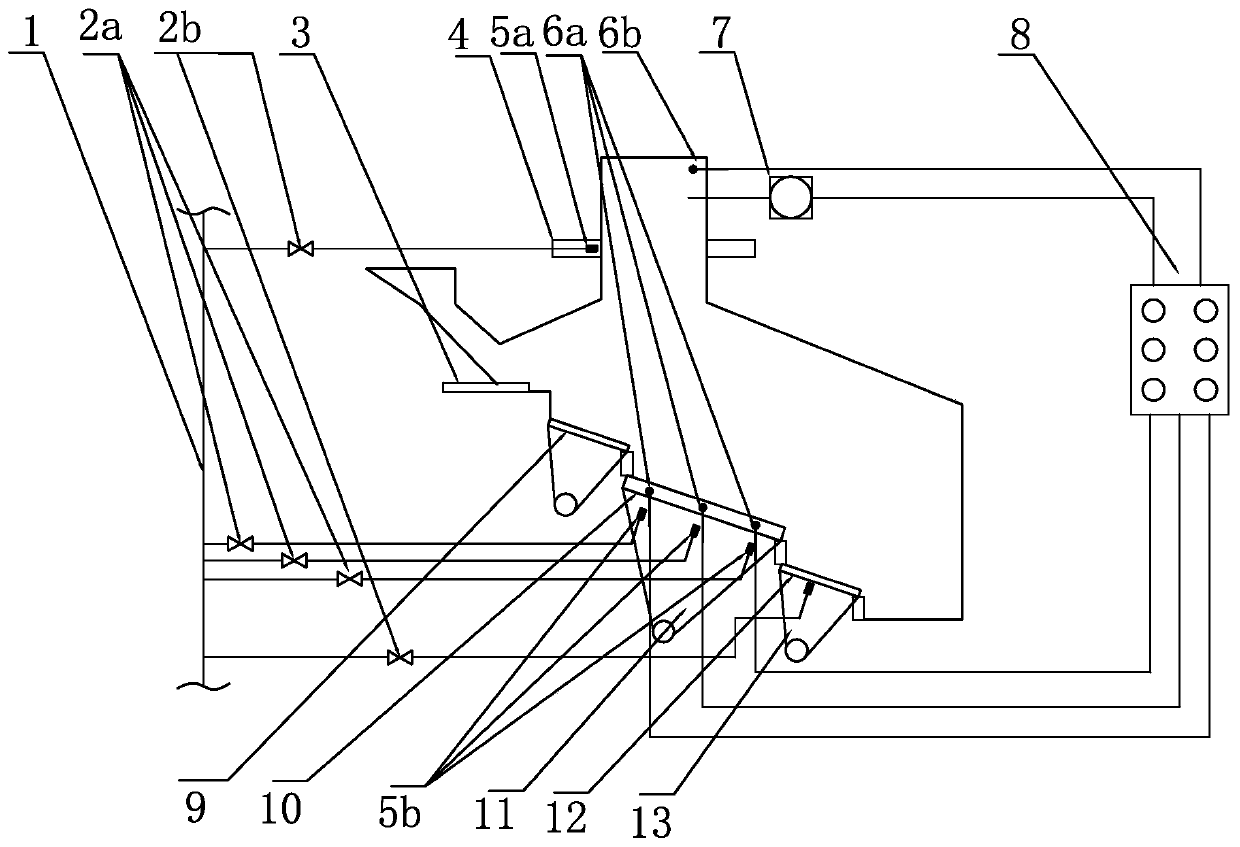

[0019] Such as figure 1 As shown, the present invention provides an oxygen combustion-supporting system for a grate type garbage incinerator, including a drying section fire grate 9, a burning section fire grate 10, and a burnout section fire grate 12 installed at the bottom of the waste incinerator in sequence. , the combustion section bellows 11 is installed below the combustion section grate 10, the burnout section bellows 13 is installed below the burnout section fire grate 12, the entrance of the drying section fire grate 9 is connected with the outlet of the metering type garbage feeder 3, An oxygen injector group 5b is installed at a position close to the combustion section fire grate 10 in the combustion section bellows 11, and the inlet of the oxygen injector group 5b communicates with the oxygen main pipe 1 through a pipeline equipped with an oxygen regulating valve group 2a. An oxygen injector 5a is installed near the position of the burnout section fire grate 12 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com