Wall manufacturing method and wall prepared by same

A production method and wall technology, applied in the processing of walls, building materials, building components, etc., can solve the problems of poor sound insulation and thermal insulation performance of wall units, complicated installation, and time-consuming, so as to improve building efficiency and improve Sound insulation performance, the effect of reducing garbage pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

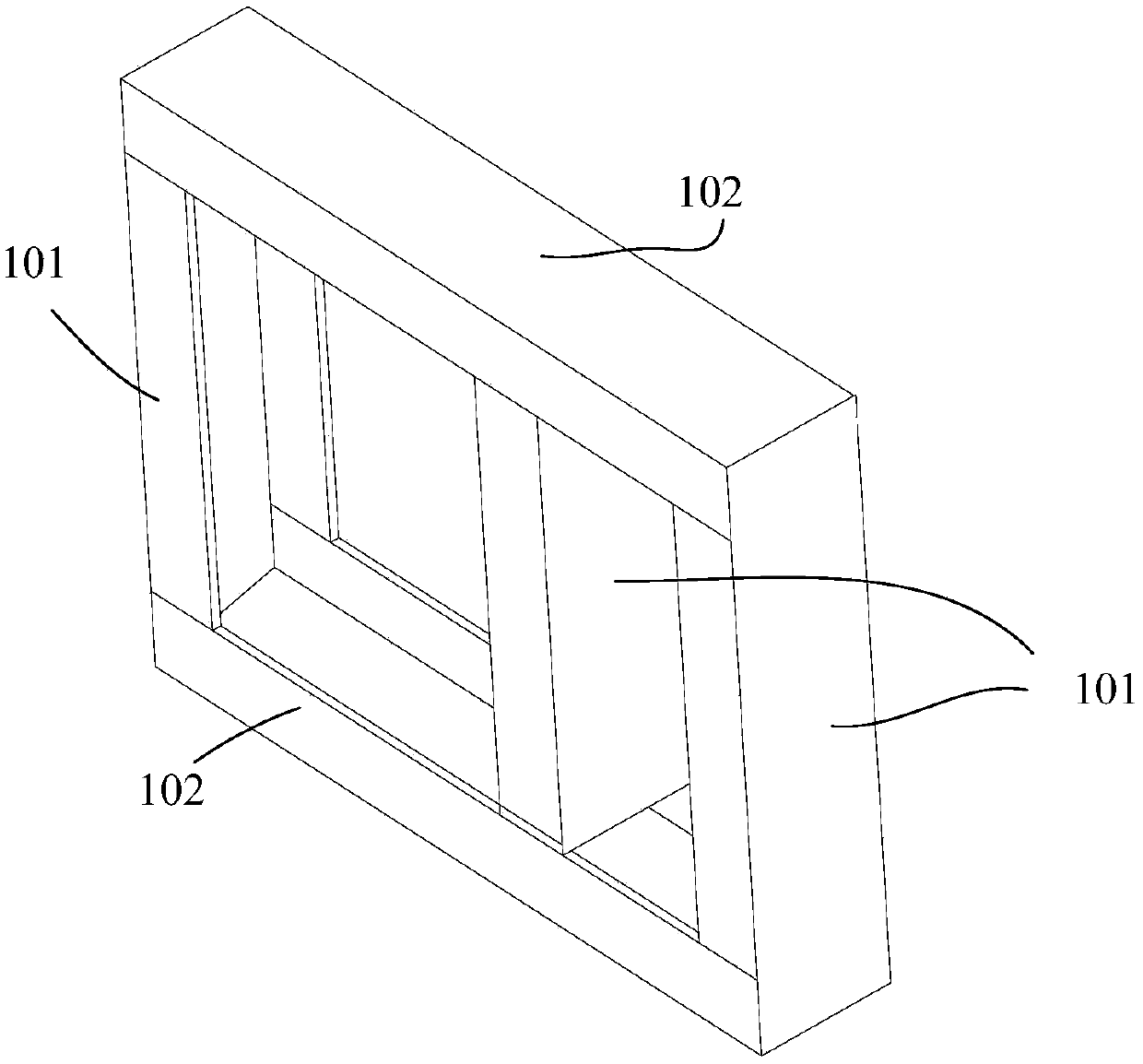

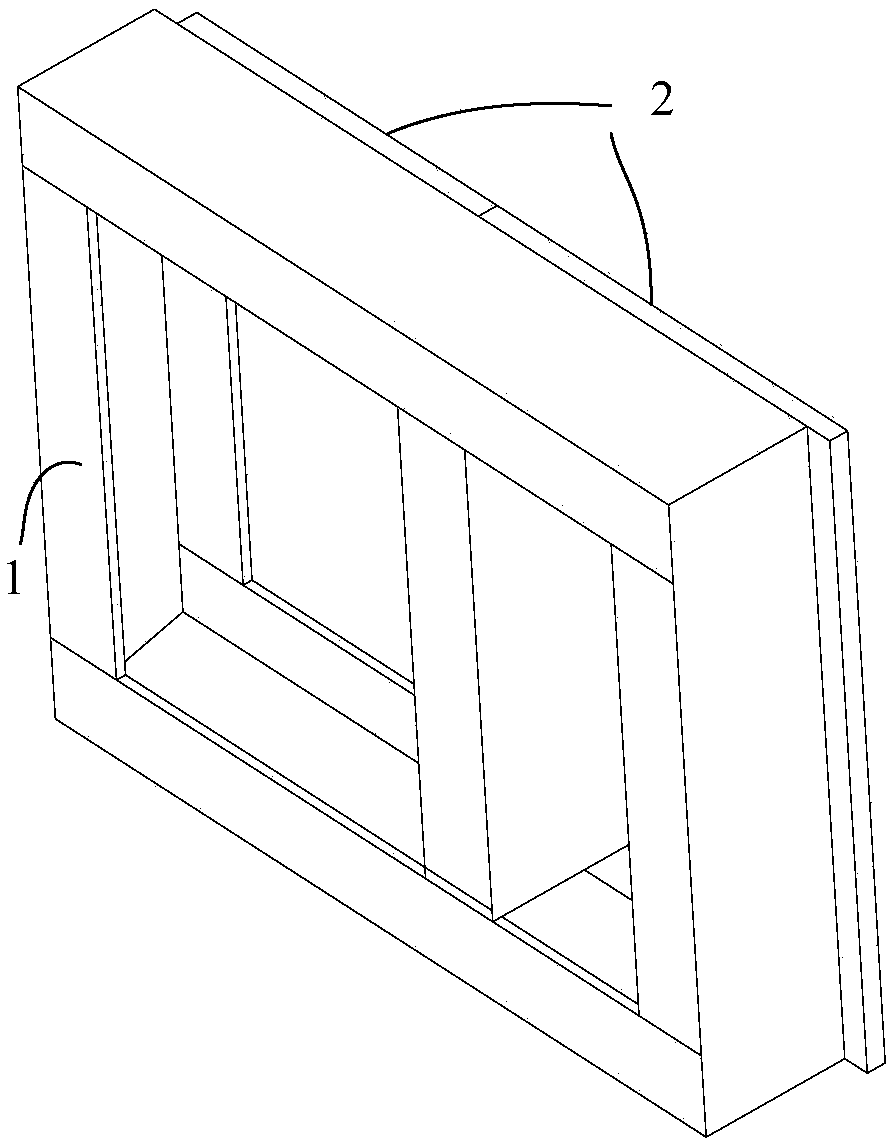

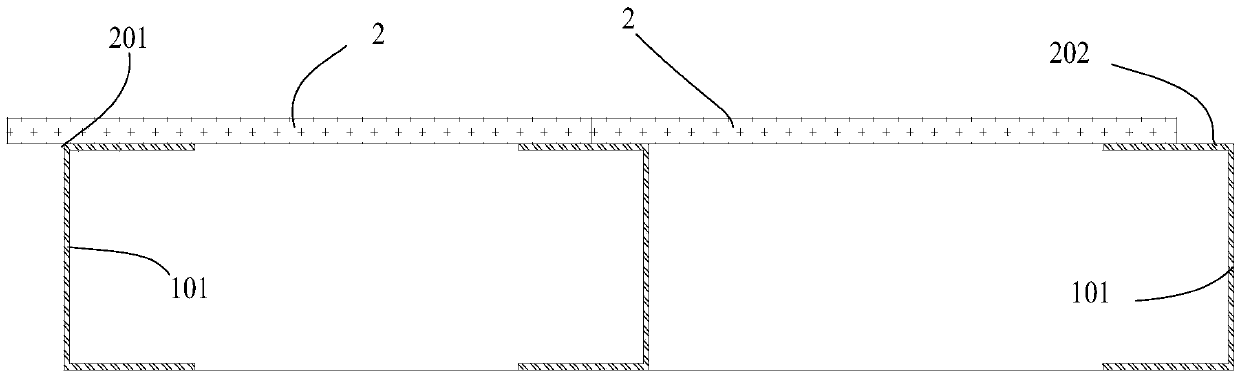

[0037] Figure 1 to Figure 6 It is the embodiment one of the body of wall of the present invention. Such as Figure 1 to Figure 6 As shown, the wall includes a plurality of wall units 4 that are linearly joined together, and a plurality of second wall panels 5 fixed on one side of the wall unit 4, wherein the wall unit 4 includes a keel frame 1 and a closed keel A plurality of first wallboards 2 on one side of the skeleton 1 and an insulating material 3 filled in the keel skeleton 1 , and the insulating material 3 is bonded to the first wallboard 2 . In particular, tenons 201 and mortises 202 for insertion are respectively formed at both ends of the wall unit 4 in the length direction, so that adjacent wall units 4 are inserted into each other, and the second wall panel 5 closes the keel frame 1. The other side is arranged asymmetrically with the first wallboard 2 . The wall can be quickly and conveniently assembled, dry construction, water saving and energy saving, fast an...

Embodiment 2

[0041] Figure 7 It is the second embodiment of the body of wall of the present invention. The substantial difference between the second embodiment and the first embodiment is that: there are sound insulation materials between the wall units.

[0042] Specifically, as Figure 7As shown, a sound-insulating material 8 is sandwiched between two adjacent wall units 4 , and the sound-insulating material 8 blocks the sound propagation path between the two wall units 4 and plays a certain role of heat insulation. Before the two wall units 4 are spliced, the sound-insulating material 8 is pre-fixed at the joint of any wall unit 4. After the two wall units 4 are spliced, the two wall units 4 extrude the sound-insulating material 8, and fasten the two walls with screws. The wall body wall unit prevents the dislocation of the sound insulation material 8 .

[0043] Compared with the first embodiment, this embodiment can improve the sound insulation performance of the whole wall.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com