Screw anchoring part adjustable lock and using method thereof

An anchoring and adjustable technology, applied in the on-site preparation of building components, the connection of formwork/formwork/work frame, construction, etc., can solve the problems of inconvenient use, poor shearing position, affecting strength, etc. , to achieve the effect of convenient operation, improved practical value, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

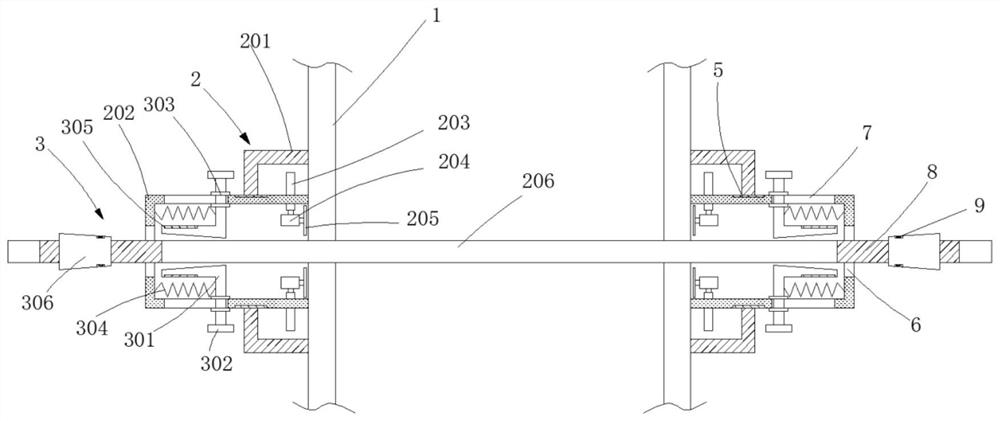

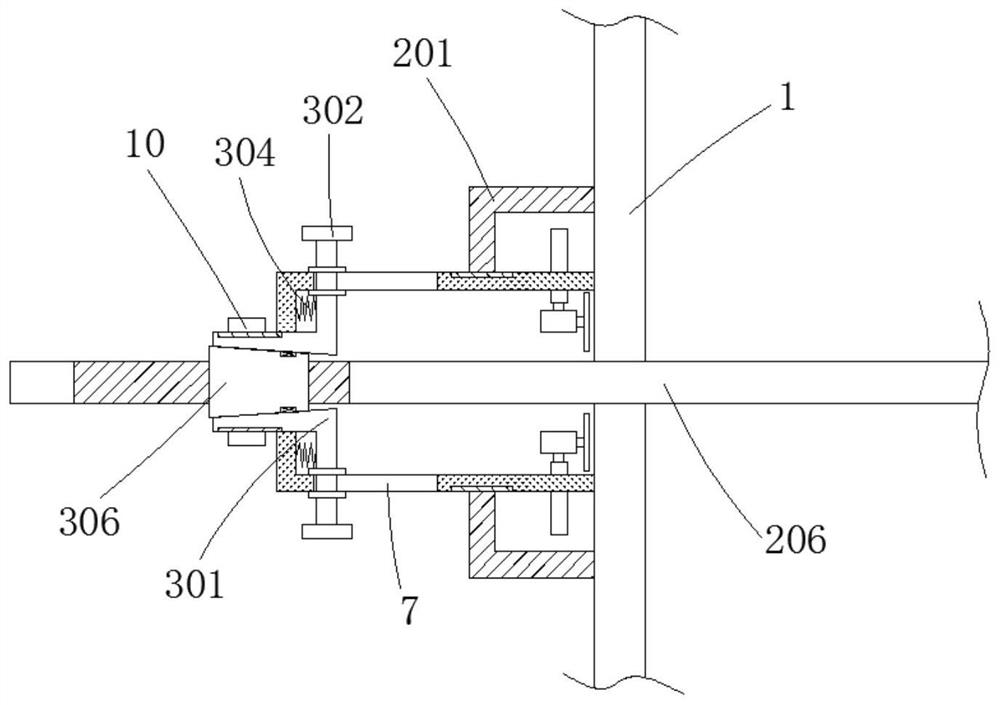

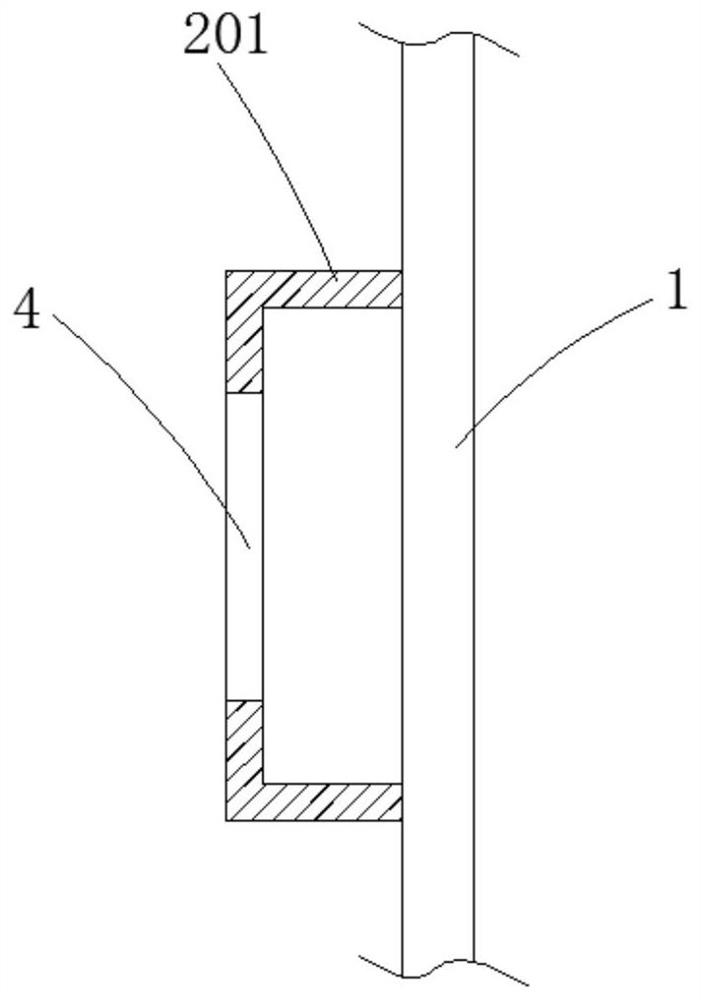

[0031] see Figure 1-5 , the present invention provides a technical solution: an adjustable screw anchor lock, including a template 1, a connecting assembly 2 and a locking assembly 3, the connecting assembly 2 includes a connecting frame 201, a connecting cylinder 202, a telescopic rod 203, a motor 204, Cutting disc 205 and connecting rod 206, template 1 is provided with two pieces, and connecting frame 201 is fixedly connected on the non-adjacent side of two templates 1, and the middle position of connecting frame 201 is provided with screw hole 4, and the outside of connecting cylinder 202 is provided with There is an external thread 5, and the connecting cylinder 202 is installed on the inner side of the screw hole 4 through the external thread 5, the telescopic rod 203 is inserted on the side wall of the connecting cylinder 202, the motor 204 is fixedly connected to the output end of the telescopic rod 203, and the cutting disc 205 Fixedly connected to the output end of t...

Embodiment 2

[0037] Compared with embodiment 1, its difference is:

[0038] Wherein, the outer side of connecting cylinder 202 is also provided with socket hole 11, and the position of connecting cylinder 202 close to motor 204 is also provided with see-through window 12, and the socket hole 11 that is set is convenient to connect power supply, makes motor and telescopic rod can carry out redundant connecting rod. cut off, thereby increasing efficiency.

Embodiment 3

[0040] Compared with embodiment 2, its difference is:

[0041] Wherein, the bottom surfaces of the horizontal sections of the two sets of movable rods 301 are respectively provided with elastic strips 13, and the thickness of the elastic strips 13 is 2mm, and the elastic strips provided can improve the cooperation effect between the anchor pipe and the movable rods so as to increase the locking force.

[0042] A method of use adopts the above-mentioned screw anchor adjustable lock, and the steps are as follows:

[0043] S1: First, support the formwork 1 on both sides of the reinforced concrete structure respectively, then pass the end of the connecting cylinder 202 provided with the perspective window 12 through the screw hole 4, and screw on the connecting frame 201 through the external thread 5, and The end of the connecting cylinder 202 is kept flush with the template 1, and then the connecting rod 206 is horizontally passed through the connecting cylinder 202;

[0044] S2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com