Integral wall production method

A production method and wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of occupying land resources, poor thermal insulation of walls, low work efficiency, etc., and achieve high construction efficiency, smooth walls, and resource saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

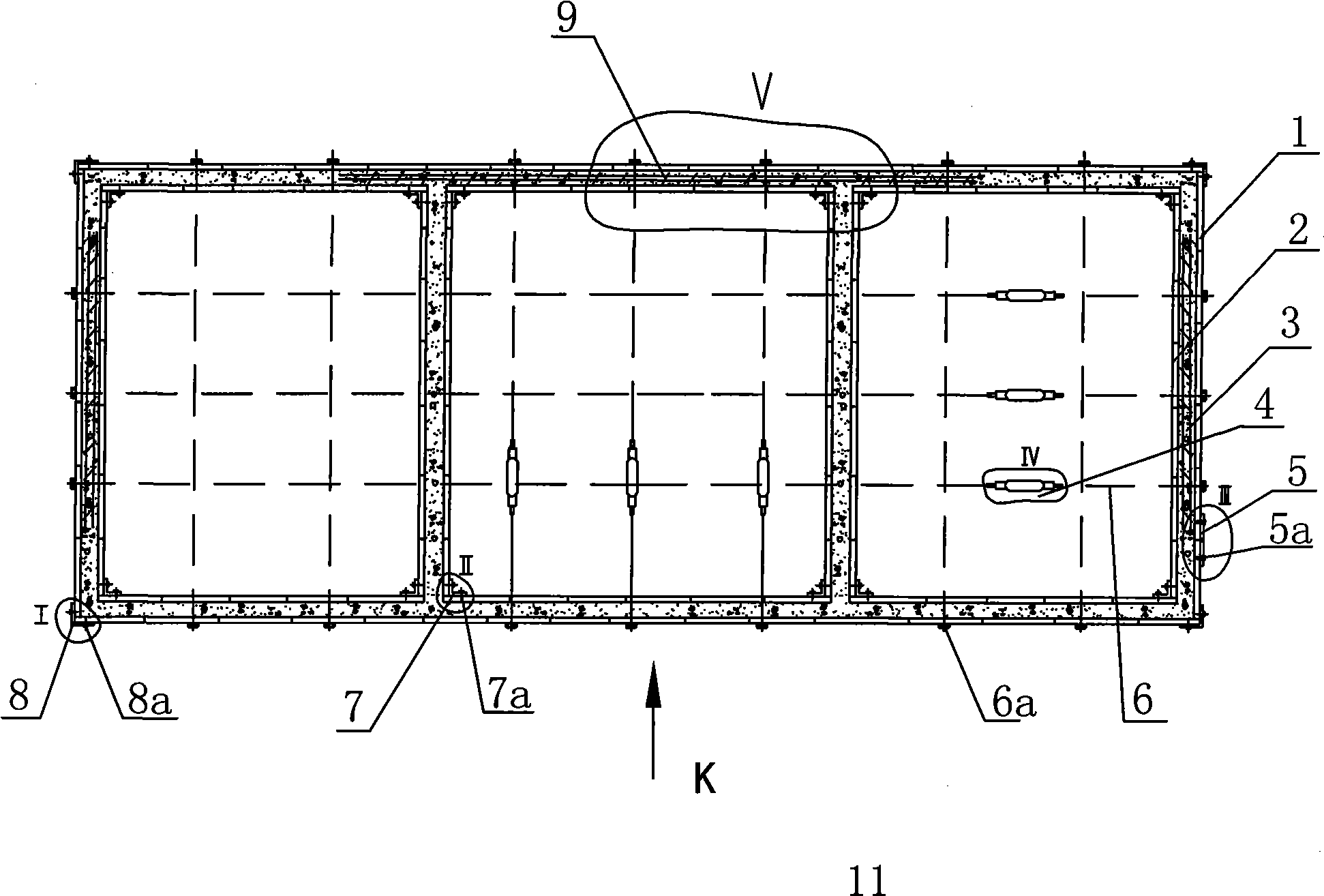

[0017] Such as figure 1 As shown, a kind of integral wall manufacture method provided by the present invention comprises the following steps:

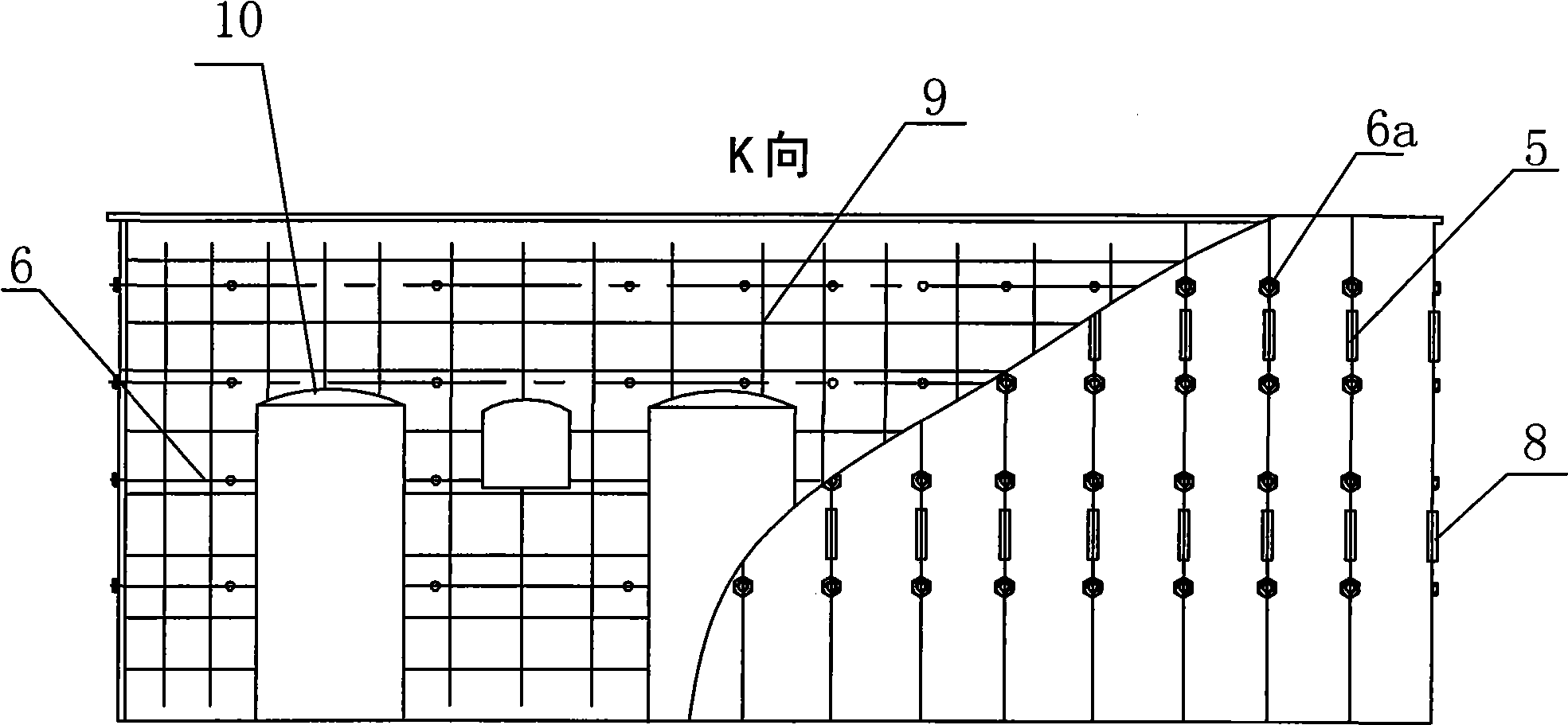

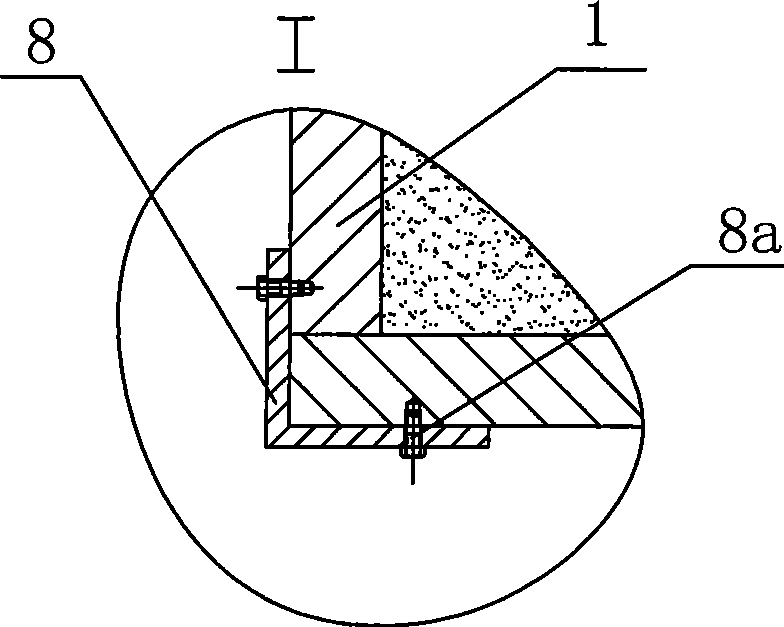

[0018] 1. Enclose the overall frame of the outer layer of the wall with the wall 1, and the overall frame of the inner layer of the wall with the wall 2 to divide the interior wall. The hoarding board can adopt a steel formwork, which is connected by connectors to form an overall frame containing the wall. The connectors are divided into three types. The first is that two steel formworks are connected by a hinge 5 and connected on the steel formwork by screws 5a. See Figure 5 . The second is that the inner and outer corners are connected by angle steel 7 and angle steel 8 respectively, and connected to the steel formwork by screws 7a and 8a, as image 3 , Figure 4 shown. The third is the fastening bolt 6 that runs through the overall frame, such as figure 1 , Figure 6 As shown, the outer ends of the fastening bolts 6 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com