Prestressed tensile reinforcement method for juxtaposed t-beam lateral linkages

A technology of lateral connection and pre-stressing, applied in the direction of bridge reinforcement, bridge, bridge construction, etc., can solve the problems of large local stress, poor durability, web cracking, etc. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A prestressed tensile reinforcement method for juxtaposed T-beam lateral connection, which is implemented in sequence according to the following steps:

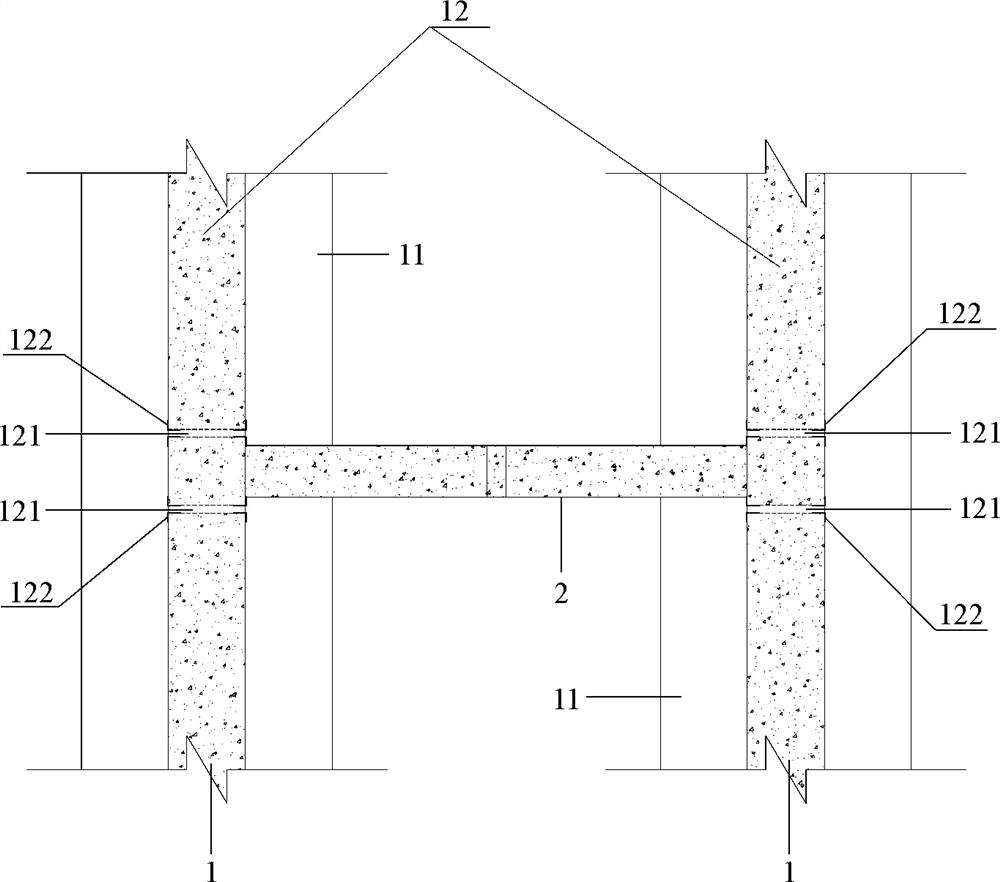

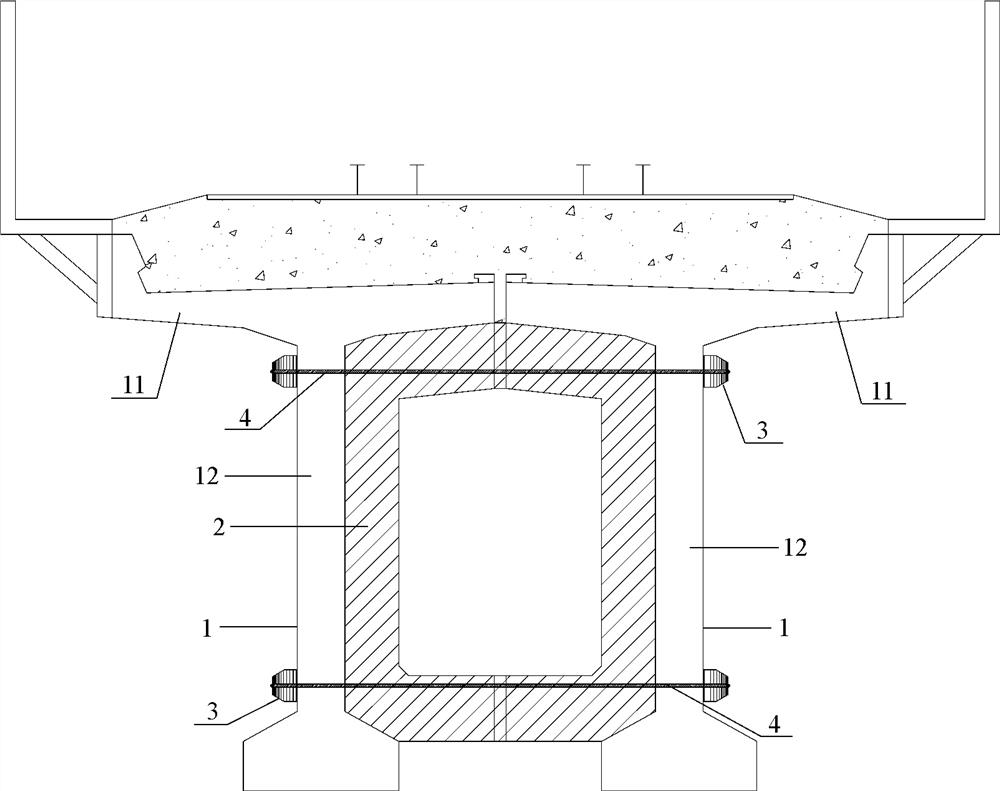

[0039] ① Set the transverse beam, such as figure 1 As shown: the adjacent T-beams 1 are arranged opposite to each other with the flanges 11, and the two ends of the transverse beams 2 are respectively connected to the webs 12 of the adjacent T-beams 1;

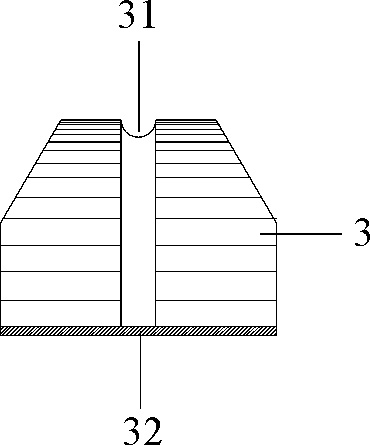

[0040] ② Drilling: such as figure 1 As shown: two anchor holes 121 are drilled on each web 12, and the two anchor holes 121 are located above and below the transverse beam 2 respectively. 1. For damage to the beam body, after cleaning the anchor hole 121, insert the rubber ring 122 into the anchor hole 121 to prevent the drag cable 4 from being damaged by the friction of the anchor hole 121; Facing the transverse beam 2, such as figure 2 As shown: the bottom of the steering slider 3 is fixed on the outside of the web 12 through a rubber water stop plate 32 with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com