High-stability sectional type cast-in-situ bored pile construction method

A bored pile, high stability technology, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of ground environment derailment, uneven strength, broken piles, etc., to control construction costs and improve stability and safety, reducing the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

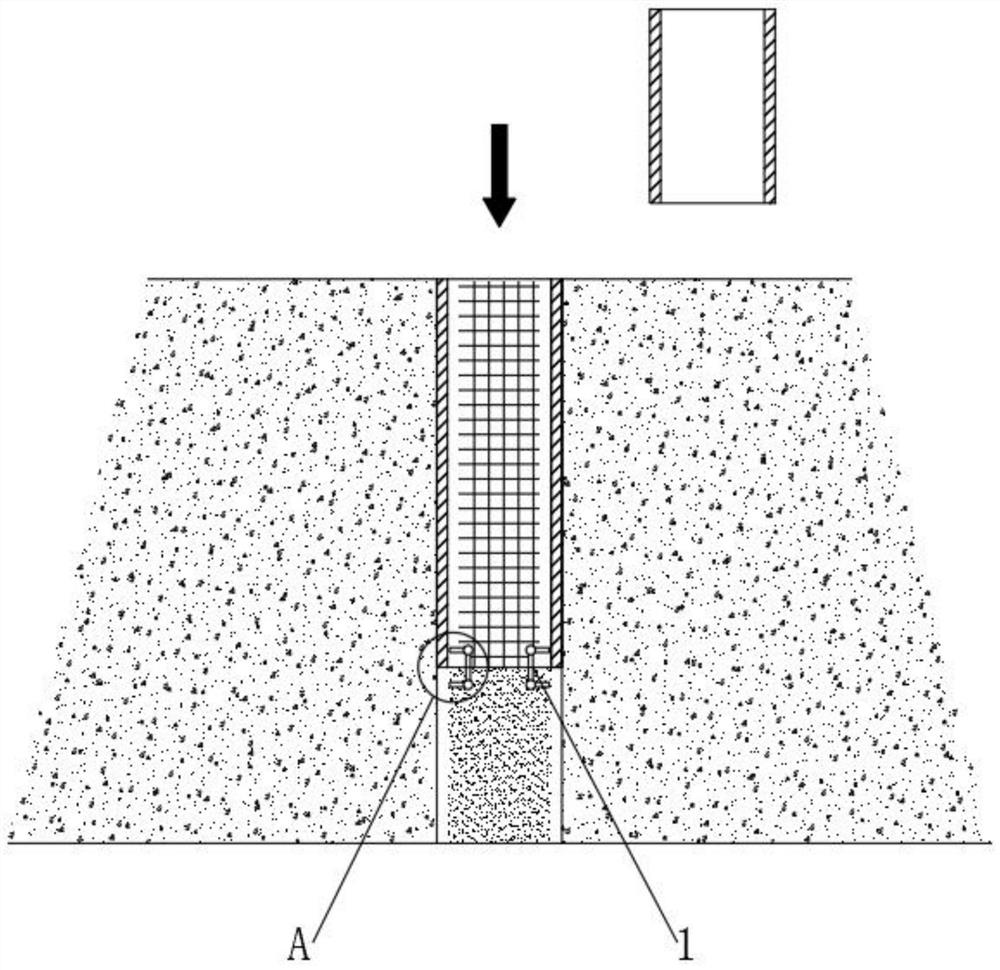

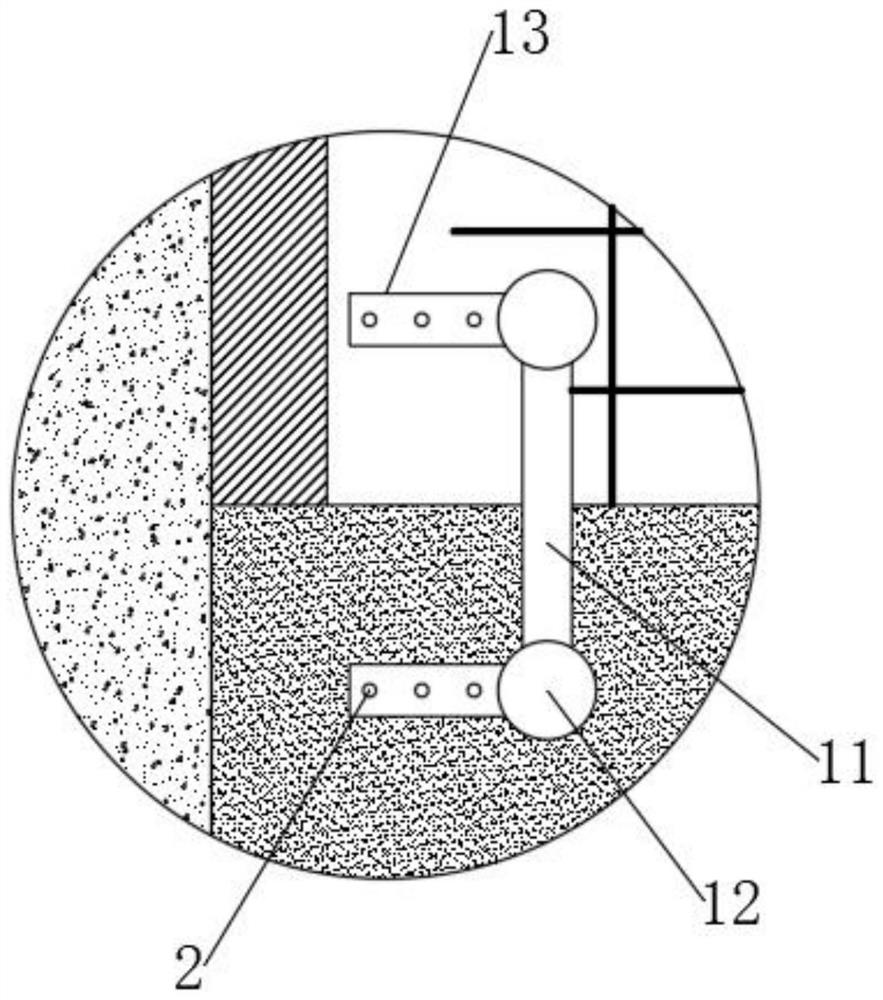

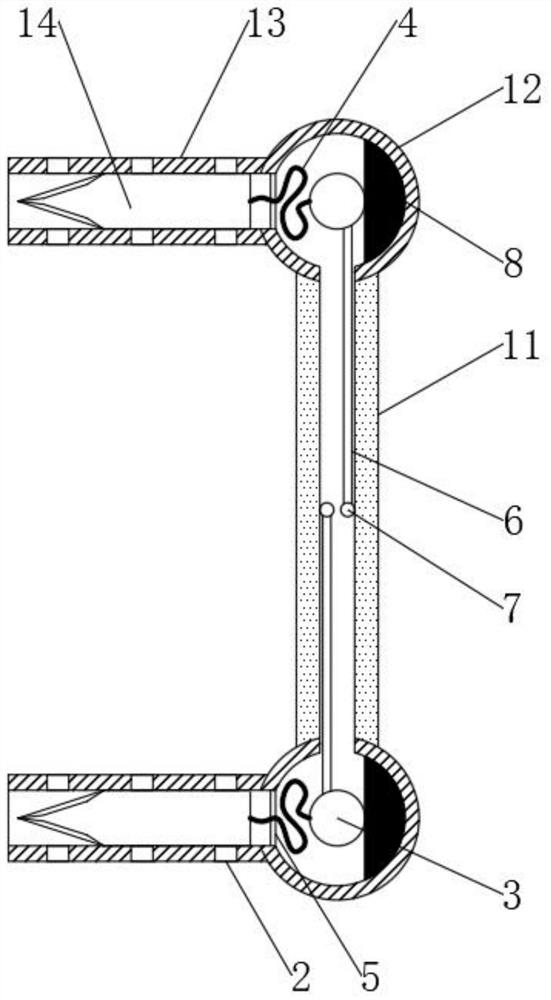

[0043] see figure 1 , a construction method for high-stability segmented bored piles, comprising the following steps:

[0044] S1. Construction personnel, materials and equipment enter the site one after another to level the construction site and determine the hole positions;

[0045] S2, bury the multi-section casing, then install the drilling machine and perform positioning, and then prepare the mud for use;

[0046] S3. The drilling machine starts drilling, injects mud and extracts slag in real time during the process, and cleans the hole after the drilling is completed;

[0047] S4. According to the length of the cast-in-situ pile, select an appropriate number of double-effect monitoring rods 1 and evenly weld them on the bound steel cage, then hang the steel cage vertically into the hole position, and fix it after positioning;

[0048] S5. Concrete is poured in sections with a conduit. The pouring height should reach half of the specified double-effect monitoring rod 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com