Co-crosslinking immobilization method of laccase

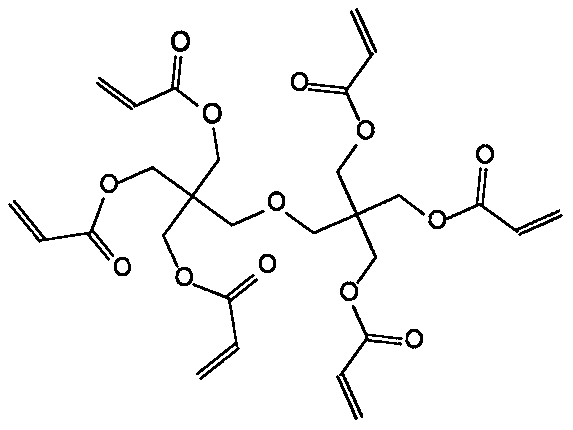

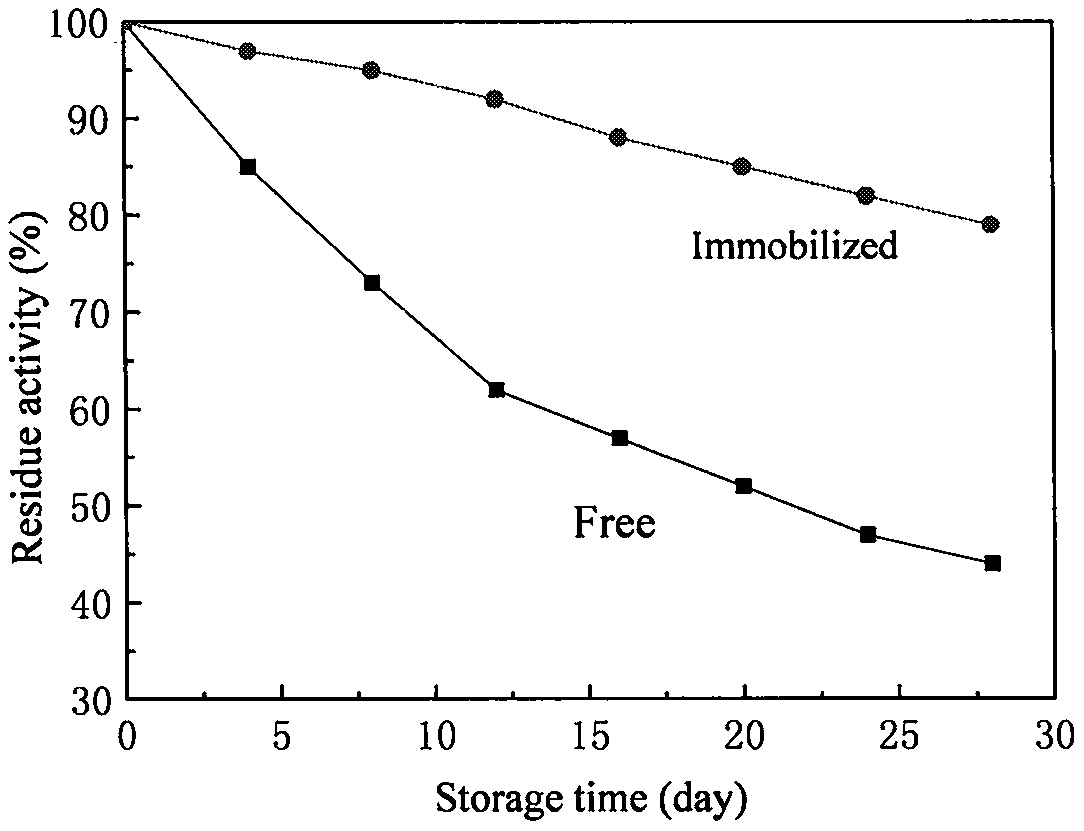

A technology of co-crosslinking and laccase, applied in immobilized enzymes, biochemical equipment and methods, immobilized on/in organic carriers, etc., can solve high reactivity, excessive enzyme crosslinking, blocking mass transfer channel and other issues to achieve the effect of improving catalytic reaction activity, improving catalytic performance and improving microenvironment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Enzyme immobilization

[0017] 1) Bisphenol A epoxy resin (brand name is E-44, epoxy value is 0.44, number average molecular weight is 454), three kinds of components of methanol and triethylenetetramine are mixed according to the mass ratio of 2: 2: 1.5, Stir and react in the range of 25-35°C for 4-5 hours, pour the mixture into water, wash the precipitate repeatedly with water to remove methanol and a small amount of amine, then put it in a vacuum oven and dry it at room temperature to obtain an aminated epoxy resin;

[0018] 2) Add epoxy resin amides and β-cyclodextrin into water at a molar ratio of 1:2.1 to 1:2.3, heat and stir until all epoxy resin amides are converted into molecular complexes and dissolved in water, and keep the The total mass concentration of the aqueous solution is in the range of 5 to 6wt.%.

[0019] 3) dissolving the laccase in a phosphate buffer solution with pH=6.5, and keeping the concentration of the enzyme in the range of 1.0-7.0 mg / mL; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com