Template for duplicating hydrophobic coating

A hydrophobic coating and template technology, applied in the field of materials, can solve the problems of not being suitable for large-scale production, difficult to control the etching effect, complicated preparation process, etc., and achieve good industrial application prospects, low cost, and enhanced hydrophobicity of the coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

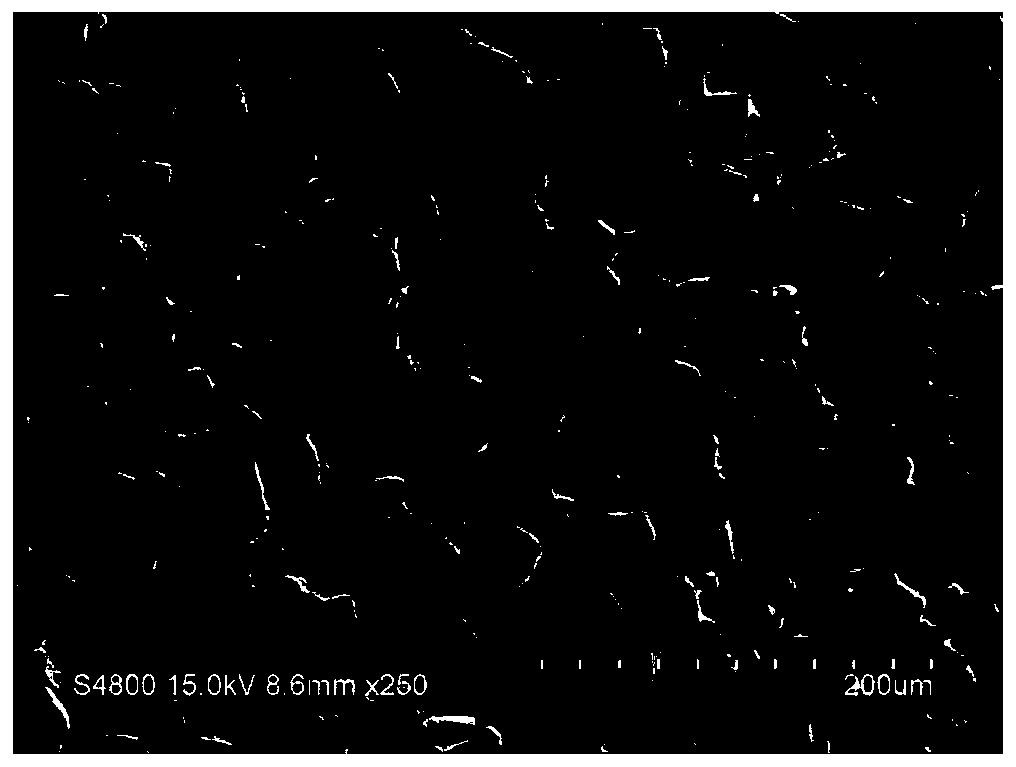

Image

Examples

Embodiment 1

[0030] Dissolve 30g of vinyl silicone resin in 70.5g of xylene, stir well, add 0.06g of defoamer (BYK-306), 0.06g of leveling agent (BYK-333), 0.2g of dibutyltin dilaurate After stirring evenly again, put it into a 90°C oven and keep it warm for 4 hours to pre-cure it to obtain a template material.

[0031] Get 20g of ammonium chloride and 15g of sodium chloride and dissolve in 200g of deionized water. Adjust the pressure of the air compressor to 0.2MPa, atomize the solution through a spray gun, spray on the surface of the template material twice, and after the salt particles crystallize, heat the template material to 170°C for 2 hours. After the curing is complete, the template material is placed in deionized water to etch away the salt particles, and finally a template for hydrophobic coating replication is obtained.

[0032] Pour an E51 epoxy resin coating with a thickness of about 1 mm on the surface of the formwork, and release it after curing to obtain an epoxy resin co...

Embodiment 2

[0035] Dissolve 10g of phenyl silicone resin and 15g of vinyl silicone resin in 74.4g of xylene, stir well, add 0.2g of defoamer (BYK-A535), 0.2g of leveling agent (BYK-380N), 0.2g of sulfur Dioctyltin alcohol, stirred evenly again, put it into an oven at 80°C for 8 hours to keep it warm for pre-curing to obtain a template material.

[0036] Dissolve 35g of potassium carbonate in 100g of deionized water. Adjust the pressure of the air compressor to 0.8MPa, atomize the solution through a spray gun, and spray it on the surface of the resin for 4 times, after potassium carbonate crystallizes. Heat the template material to 220°C for 2h. After curing is complete, the template material is placed in deionized water to etch away the salt particles, and finally a template for hydrophobic coating replication is obtained.

[0037] Pouring a polydimethylsiloxane coating with a thickness of about 1 mm on the surface of the formwork, and demoulding after curing, a polydimethylsiloxane coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com