Thermoplastic prepreg slurry based on slurry method and preparation method

A thermoplastic and prepreg technology, which is applied in the field of prepreg slurry, can solve the problems of poor stability of thermoplastic resin powder slurry, and achieve the effects of ensuring impregnation effect, improving stability, and facilitating concentration control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

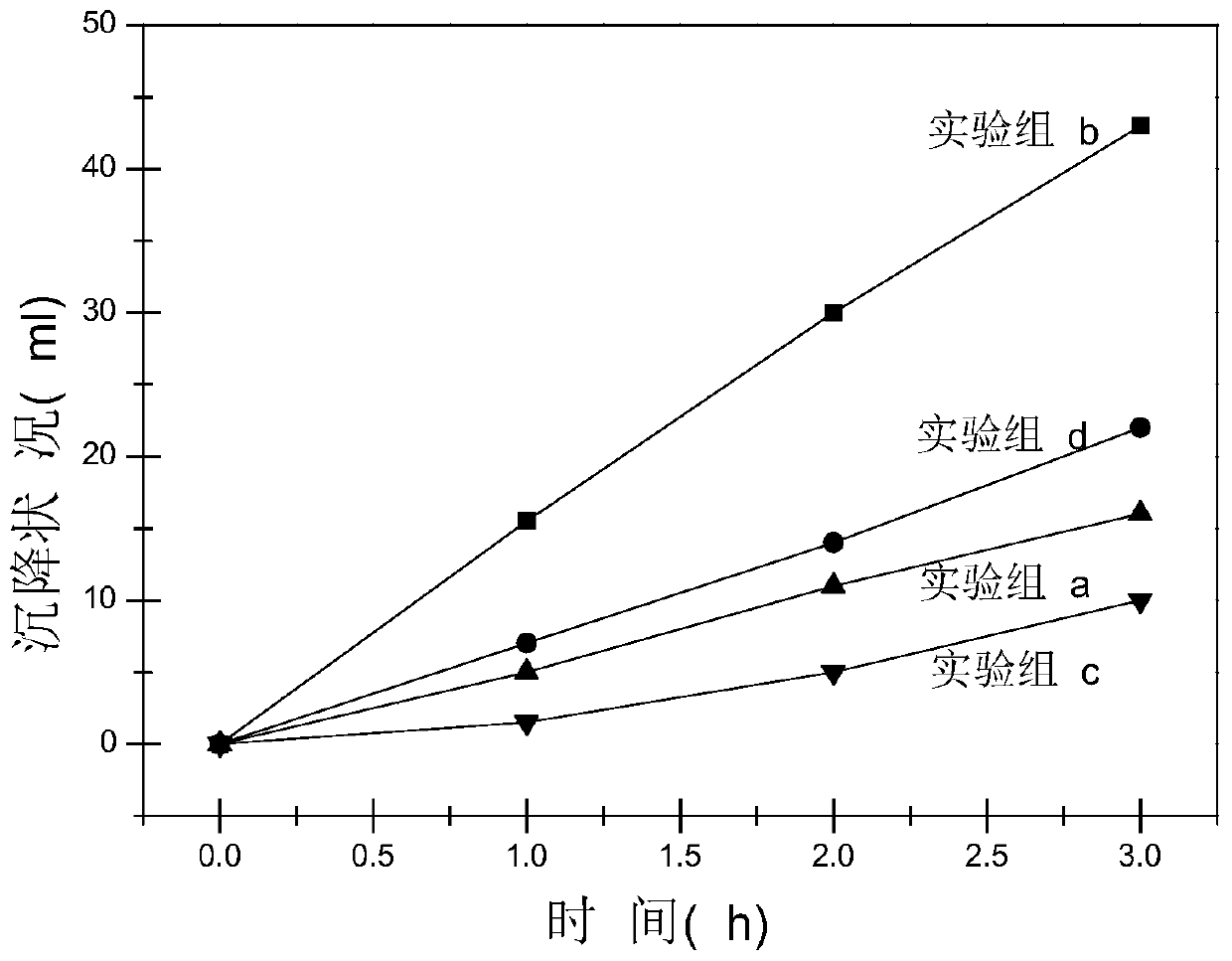

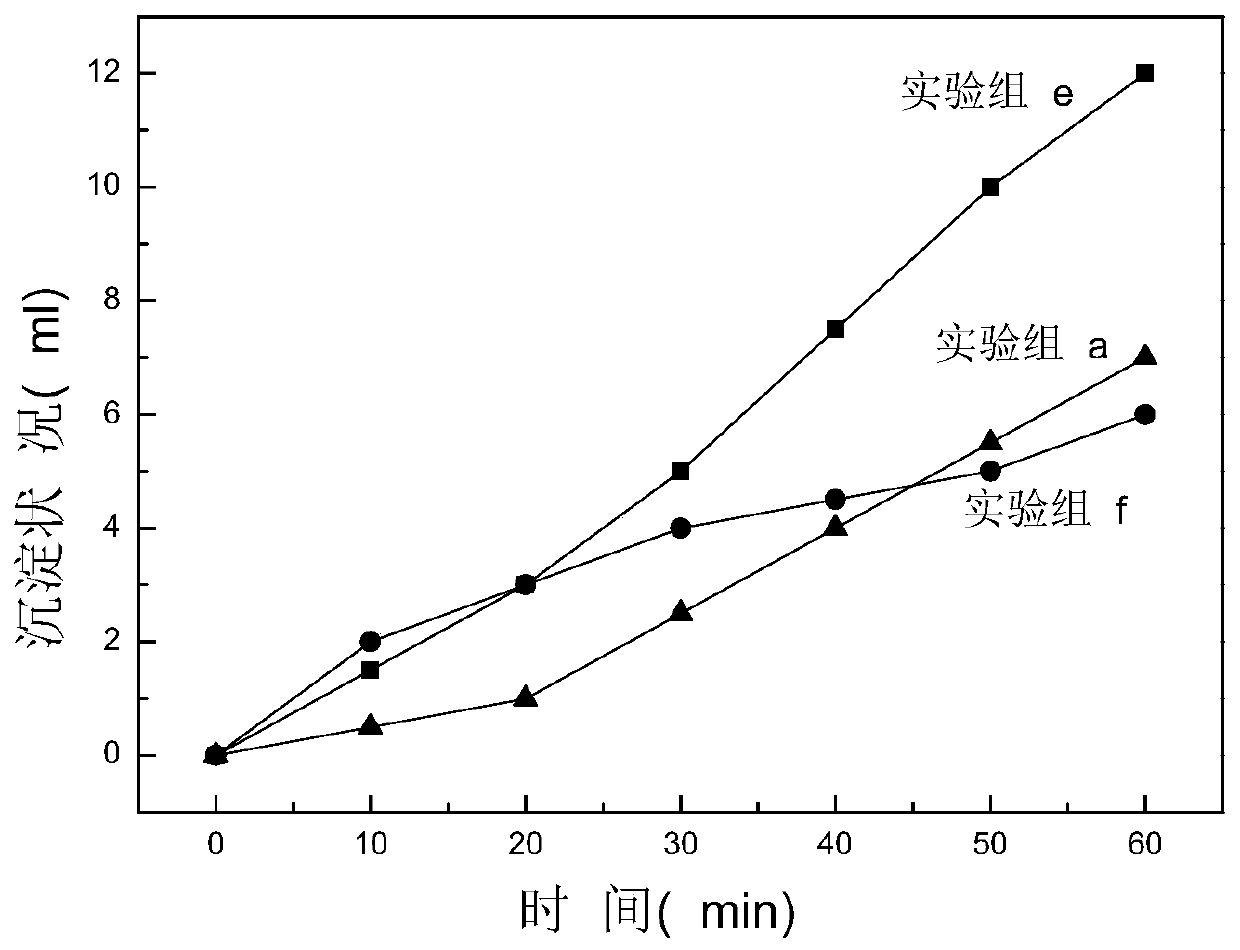

Examples

Embodiment 1

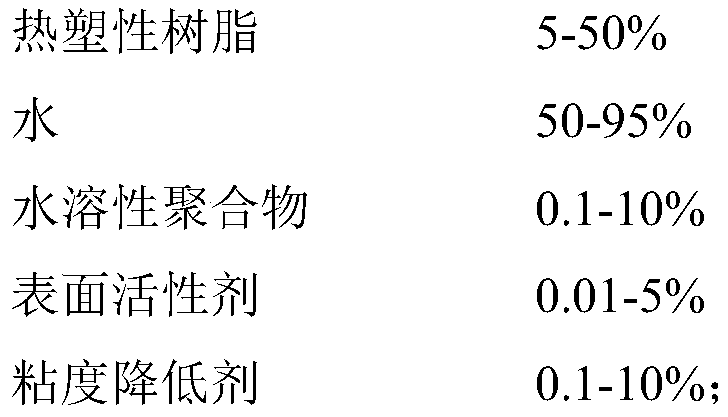

[0046] The slurry formula is shown in Table 1:

[0047] Table 1

[0048]

[0049]

[0050] Note: In the table, resin powder and deionized water are mixed as 100 parts (100%), and other additives are calculated separately due to the small amount of addition. The percentage of all additives is based on (the weight of resin powder and deionized water), that is, the percentage of the total amount of resin and deionized water, such as the amount of water-soluble polymer = (the weight of resin powder and deionized water)* 0.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com