Stainless steel coating, preparation method thereof and preparation method of solid phase components

A stainless steel and coating technology, applied in the direction of coating, metal material coating process, heating inorganic powder coating, etc., can solve the problems of damage, easy oxidation, etc., to improve wetting performance, enhance water resistance, increase reactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

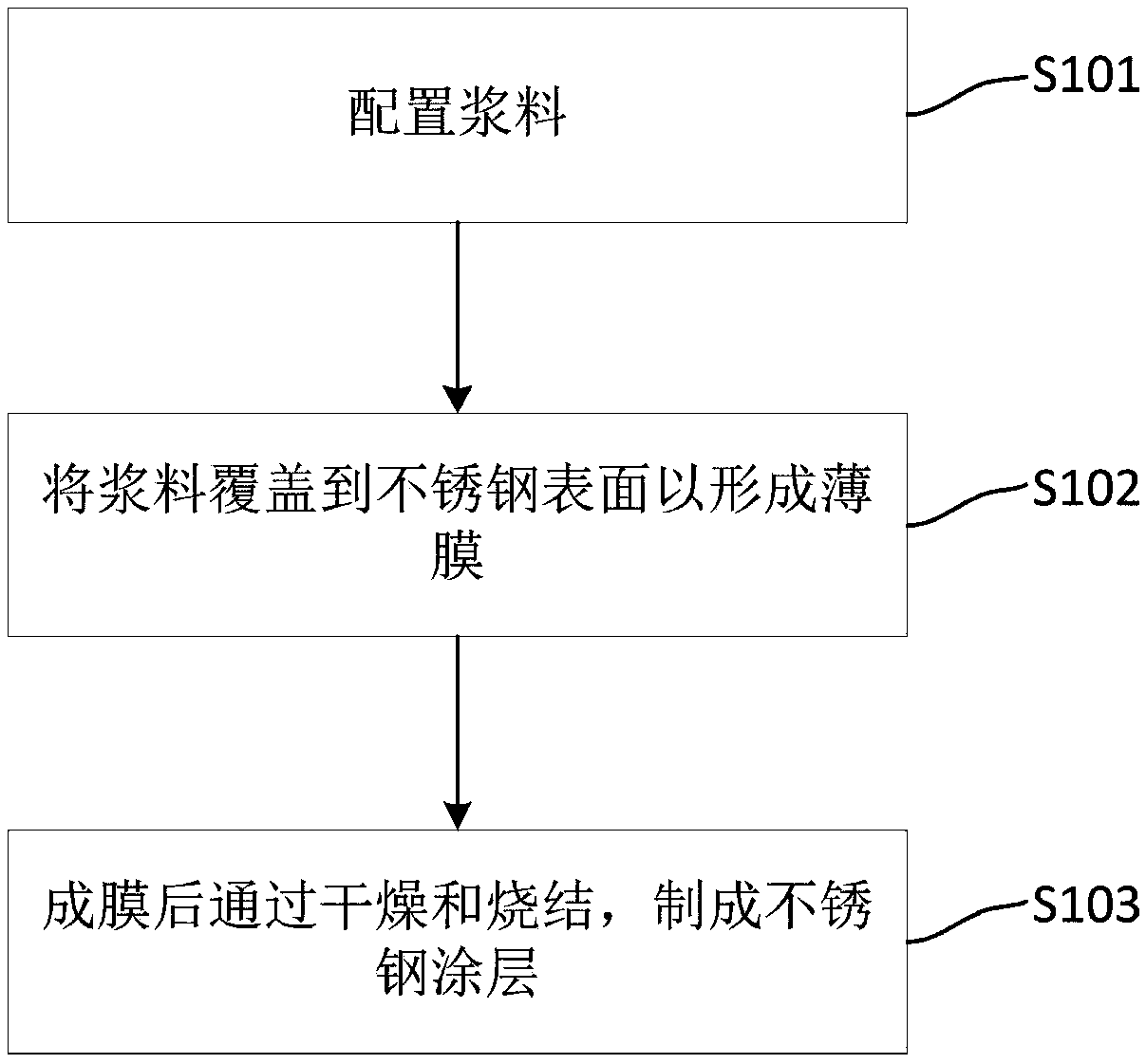

[0034] For another implementation based on the above-mentioned embodiment, refer to figure 1 As shown, a method for preparing a stainless steel coating is provided in this embodiment, comprising the following steps:

[0035] Step 1 S101: configuring slurry;

[0036] Step 2 S102: Cover the slurry on the stainless steel surface to form a thin film;

[0037] Step 3 S103: drying and sintering after film formation to form the stainless steel coating.

[0038] Specifically, the slurry is covered on the surface of the stainless steel by dipping, spraying or brushing to form the film. In Step 3 S103, the film is first dried at 80-100°C, and then sintered at 900-1000°C.

[0039] Specifically, the slurry mainly consists of 20-70 parts by weight of solid phase components and 30-80 parts by weight of organic solvent.

[0040] Specifically, the organic solvent is mainly composed of 40-80 parts by weight of terpineol, 3-10 parts by weight of ethyl cellulose, 5-20 parts by weight of xyle...

Embodiment 1

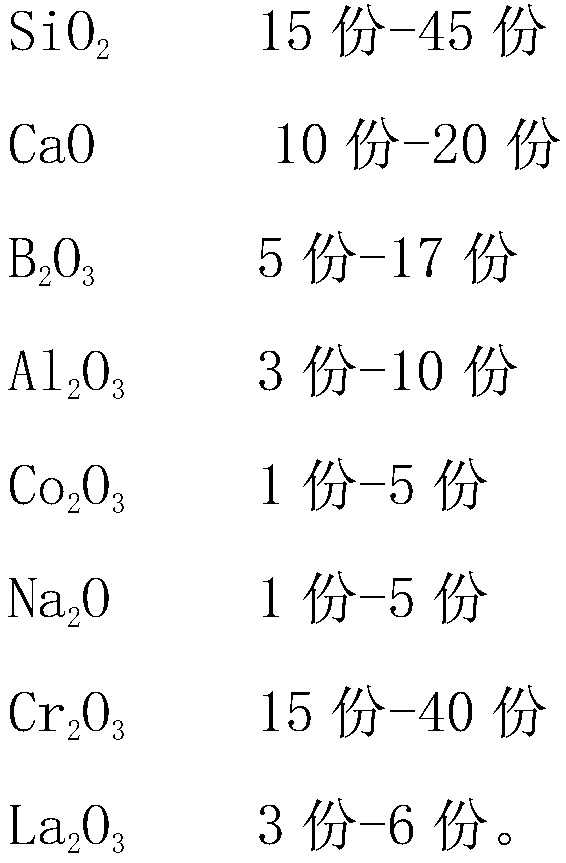

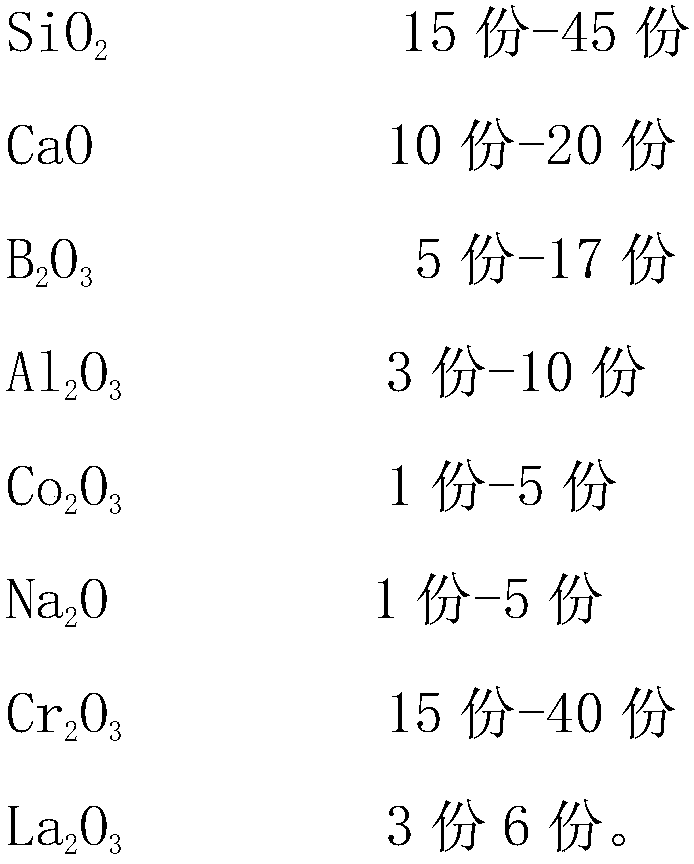

[0054] On the substrate of SUS410 stainless steel, a layer of glass ceramic coating with a thickness of 30 μm is applied on the surface by dipping method. The coating is mainly made of the following components by weight:

[0055]

[0056]

[0057] The mass ratio of impregnation slurry powder and organic solvent is 1:1; the organic solvent is mainly made of the following components by weight:

[0058]

[0059] After drying, pre-sinter at 600°C for 1 hour, and then sinter at 1000°C for 2 hours. The coated coating exhibits good oxidation resistance at 900°C and high temperature thermal cycle performance for a long time. The glass-ceramic coating is oxidized at 900°C for 24 hours, and the weight gain of the coating does not exceed 1%. After 82 cycles of cooling and heating at room temperature to 900°C, the coating has no cracking or peeling off. The uncoated SUS410 stainless steel is oxidized at 900 ° C for 12 hours, which will cause oxidative spalling.

Embodiment 2

[0061] On the substrate of SUS410 stainless steel, a layer of glass ceramic coating with a thickness of 80 μm is applied on the surface by dipping method. The coating is mainly made of the following components by weight:

[0062]

[0063] The mass ratio of the dipping slurry powder to the organic solvent is 2:1; the organic solvent is mainly made of the following components by weight:

[0064]

[0065] After drying, pre-sinter at 600°C for 1 hour, and then sinter at 1000°C for 2 hours. The coated coating exhibits good oxidation resistance at 900°C and high temperature thermal cycle performance for a long time. The glass-ceramic coating is oxidized at 900°C for 120 hours, and the weight gain of the coating does not exceed 1%. After 48 cycles of cooling and heating at room temperature to 900°C, the coating has no cracking or peeling off. The uncoated SUS410 stainless steel is oxidized at 900 ° C for 12 hours, which will cause oxidative spalling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com