Preparation method and application of 0D/2D heterostructure composite cathode material

A technology of heterostructure and negative electrode material, which is applied in the fields of nanotechnology, negative electrode, structural parts, etc. for materials and surface science, can solve the complex preparation process of LTO composite material, low energy density, low tap density, etc. problems, to achieve the effect of being conducive to large-scale production and market promotion, and improving the low specific capacity and large specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

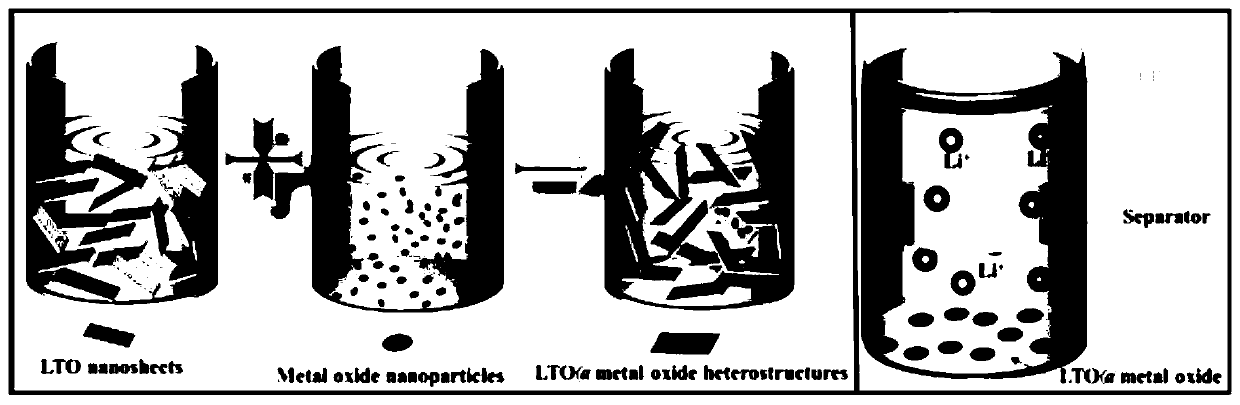

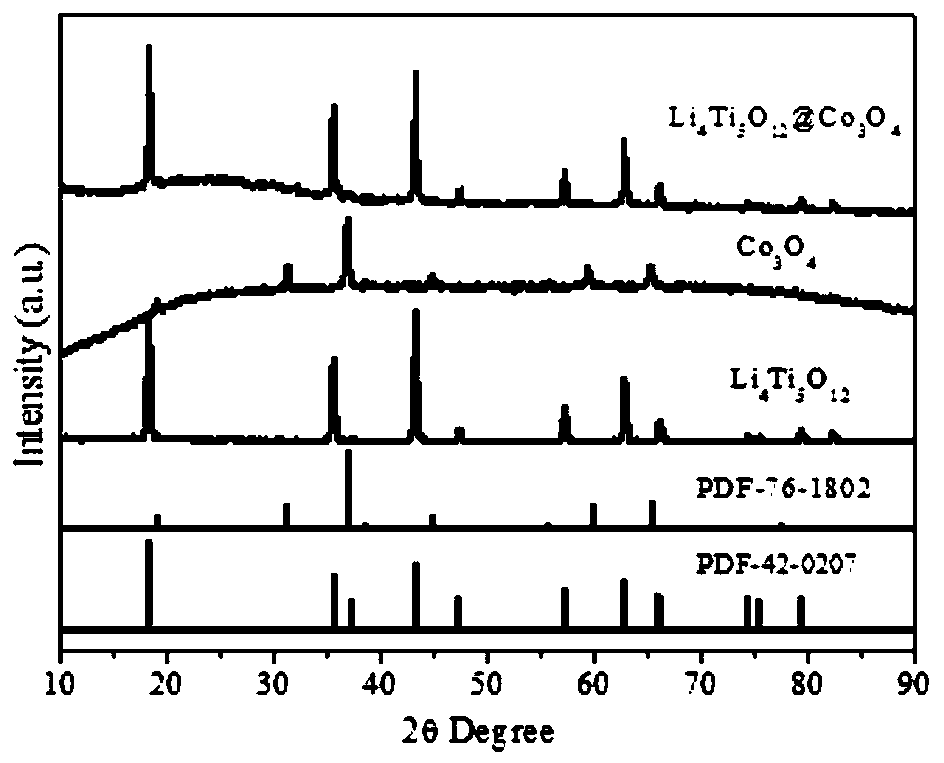

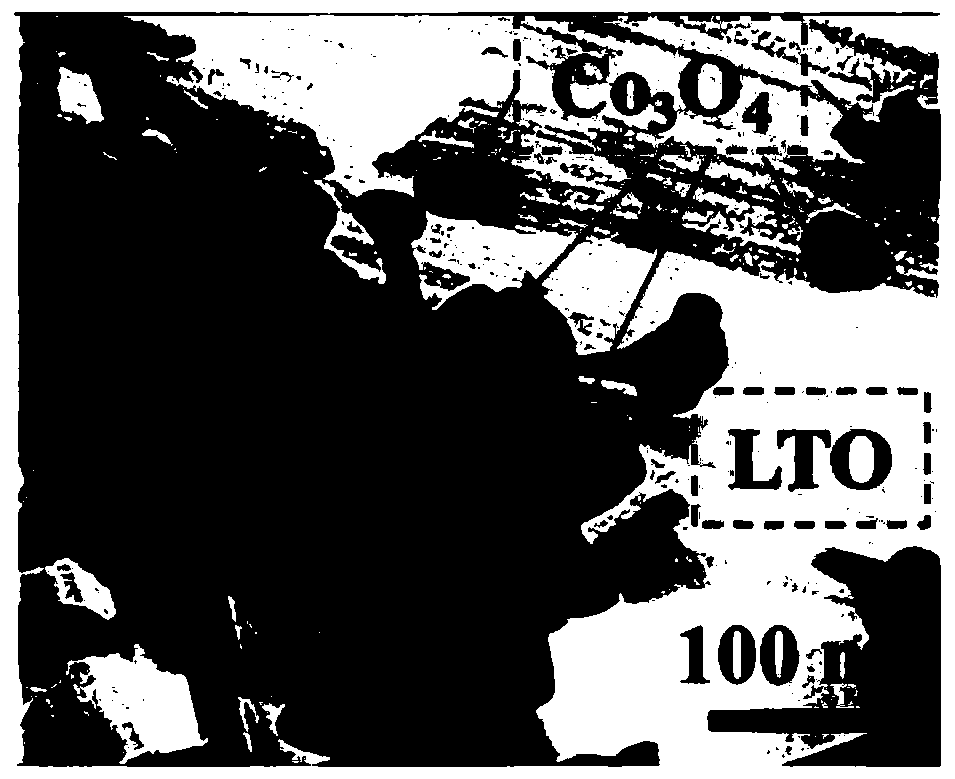

[0044] A method for preparing a 0D / 2D heterostructure composite negative electrode material, comprising the steps of:

[0045] (1) Under normal temperature conditions, dissolve 0.189g of lithium hydroxide monohydrate in 25mL of absolute ethanol by magnetic stirring for 20min, then add 1.7mL of tetrabutyl titanate dropwise, continue stirring for 12h, and finally add 25mL of Ionized water, transferred to a polytetrafluoroethylene reactor, kept at 180°C for 36h, cooled to room temperature naturally after the reaction, washed the product three times with dehydrated ethanol, dried in vacuum at 80°C for 6h, and then placed the precursor in air at 700 ℃ heat treatment for 6h to obtain two-dimensional lithium titanate nanosheets;

[0046](2) Evenly disperse 95 mg of the above-mentioned two-dimensional lithium titanate nanosheets in the organic solvent NMP to form a solution A with a concentration of 1 mg / mL; purchased, then obtained by protonation treatment, impregnated with dilute n...

Embodiment 2

[0049] A method for preparing a 0D / 2D heterostructure composite negative electrode material, comprising the steps of:

[0050] (1) Under normal temperature conditions, dissolve 0.189g of lithium hydroxide monohydrate in 25mL of absolute ethanol by magnetic stirring for 20min, then add 1.7mL of tetrabutyl titanate dropwise, continue stirring for 12h, and finally add 25mL of Ionized water, transferred to a polytetrafluoroethylene reactor, kept at 180°C for 36h, cooled to room temperature naturally after the reaction, washed the product three times with dehydrated ethanol, dried in vacuum at 80°C for 6h, and then placed the precursor in air at 700 ℃ heat treatment for 6h to obtain two-dimensional lithium titanate nanosheets;

[0051] (2) Evenly disperse 90 mg of the above-mentioned two-dimensional lithium titanate nanosheets in the organic solvent NMP to form a solution A with a concentration of 1 mg / mL; Purchased, then obtained by protonation treatment, soaked in dilute hydroch...

Embodiment 3

[0056] A method for preparing a 0D / 2D heterostructure composite negative electrode material, comprising the steps of:

[0057] (1) Under normal temperature conditions, dissolve 0.189g of lithium hydroxide monohydrate in 25mL of absolute ethanol by magnetic stirring for 20min, then add 1.7mL of tetrabutyl titanate dropwise, continue stirring for 12h, and finally add 25mL of Ionized water, transferred to a polytetrafluoroethylene reactor, kept at 180°C for 36h, cooled to room temperature naturally after the reaction, washed the product three times with dehydrated ethanol, dried in vacuum at 80°C for 6h, and then placed the precursor in air at 700 ℃ heat treatment for 6h to obtain two-dimensional lithium titanate nanosheets;

[0058] (2) Evenly disperse 80 mg of the above-mentioned two-dimensional lithium titanate nanosheets in the organic solvent NMP to form a solution A with a concentration of 1 mg / mL; Purchased, then obtained by protonation treatment, soaked in dilute hydroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com