Micron-scale high-hardness powder cleaning and separation system and method

A separation system and separation method technology, which is applied in the field of micron-level high-hardness powder cleaning and separation systems, can solve problems such as unsatisfactory effects, difficult cleaning, and complex structures, so as to reduce the risk of film plugging and material settlement, and eliminate material settlement. Problems, the effect of uniform friction cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

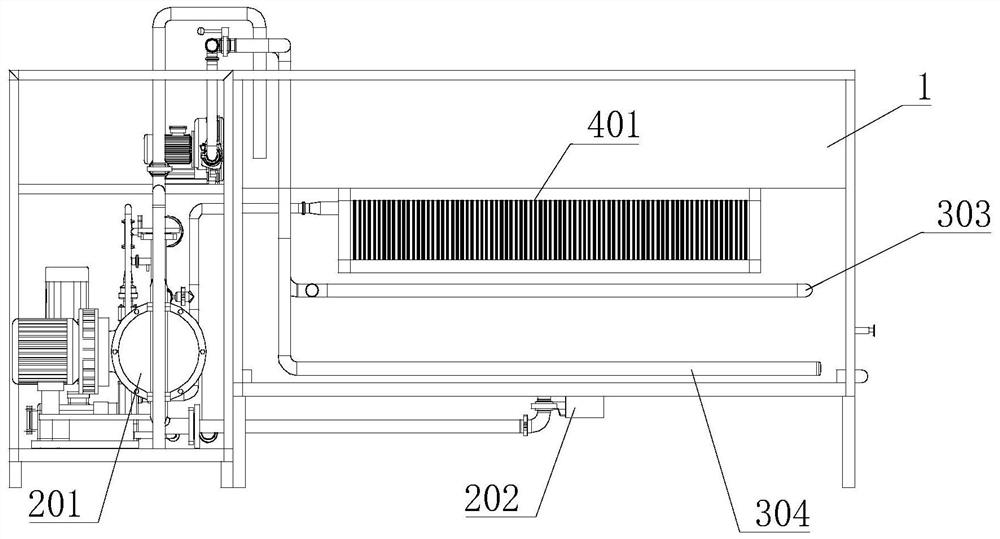

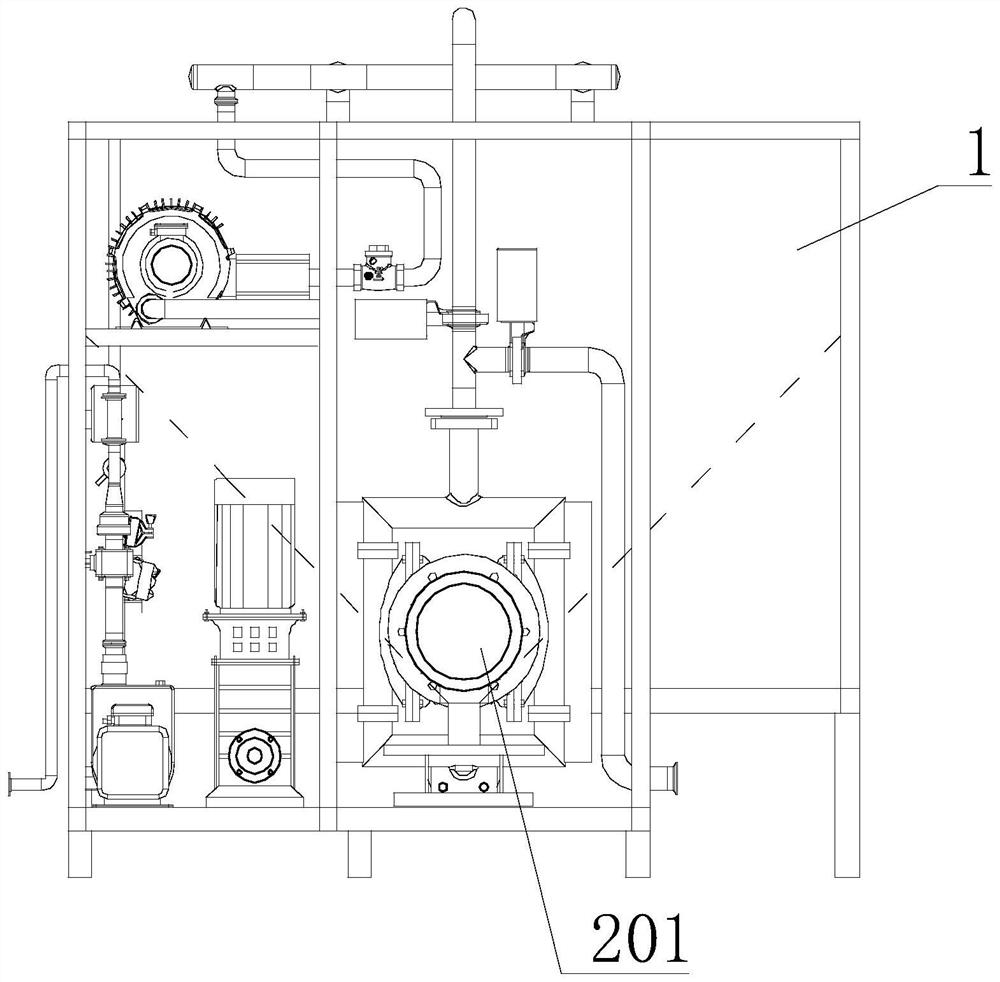

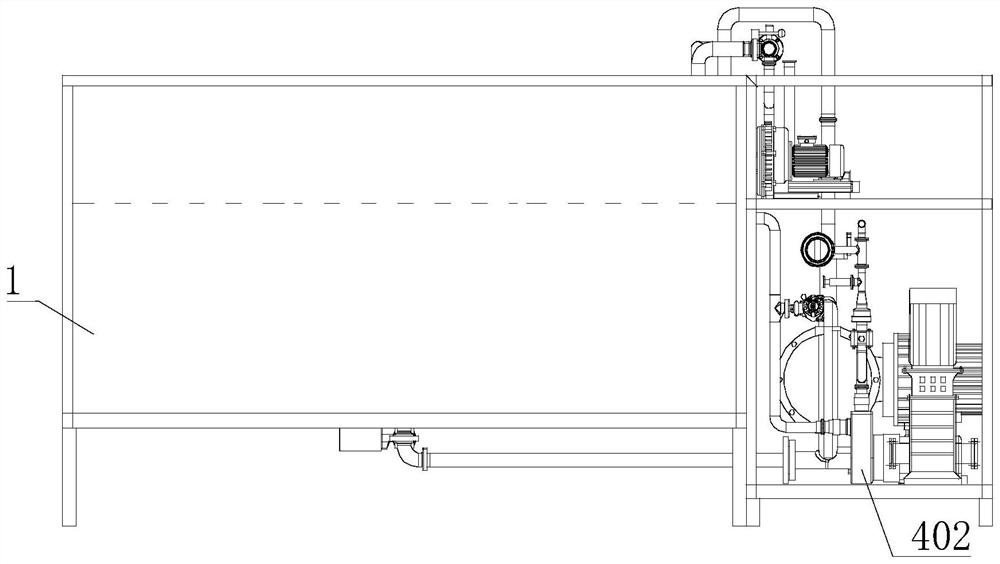

[0046] A micron-level high-hardness powder cleaning and separation system, its structure is as attached Figure 1-10shown. The system includes a membrane tank 1, a material circulation mechanism 2, an aeration mechanism 3, a ceramic flat membrane separation mechanism 4 and a water supply mechanism 5. Among them, the membrane tank 1 is used to provide a container for cleaning and separating micron-level high-hardness powders. The material circulation mechanism 2 is used to extract the slurry at the bottom of the membrane tank 1 by means of external circulation and then return it to the membrane tank 1. The aeration mechanism 3 is used to inject air bubbles into the membrane pool 1 to perform disorderly mixed friction cleaning of micron-level high-hardness powders and clean up the surface attachments of the ceramic flat plate separation mechanism 4. The ceramic flat plate membrane separation mechanism 4 is used for internal suction membrane surface filtration The washing liquid...

Embodiment 2

[0066] A method for cleaning and separating micron-level high-hardness powders, the steps of which are:

[0067] a. Add micron-sized high-hardness powder into aerated pure water to form a slurry. The weight ratio of micron-sized high-hardness powder to pure water is 1:3 or 1:2.

[0068] b. Aerate the slurry, chaotic friction cleaning, use ceramic flat membrane to separate and clean the waste liquid, and supplement pure water at the same time, the discharge of waste liquid is less than the amount of pure water supply, and carry out external circulation of the slurry to prevent sedimentation.

[0069] c. After the cleaning is qualified, stop adding pure water, maintain the operation of aeration and ceramic flat membrane separation and cleaning waste liquid, and concentrate until the weight ratio of micron-level high-hardness powder to pure water is 1:1.

[0070] d. Stop the operation of ceramic flat membrane separation and cleaning waste liquid, and discharge.

[0071] Specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com