Non-solid waste filling mining method for gently inclined medium-thick ore bodies based on ellipsoid drawing structure

An ellipsoid and ore body technology, applied in the field of gently inclined medium-thick ore body without solid waste filling mining method, can solve the problems of tailings accumulation, the blasting effect cannot meet the design requirements, and the ore self-flow ore discharge cannot be realized. , to achieve the effect of protecting the ecological environment and eliminating surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

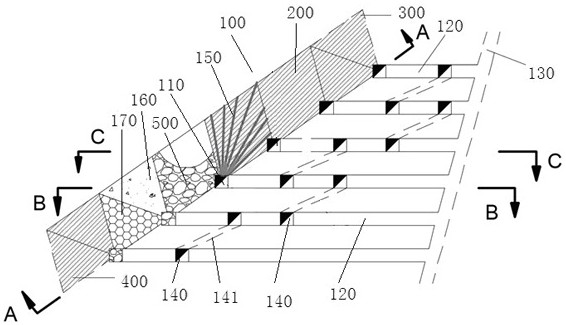

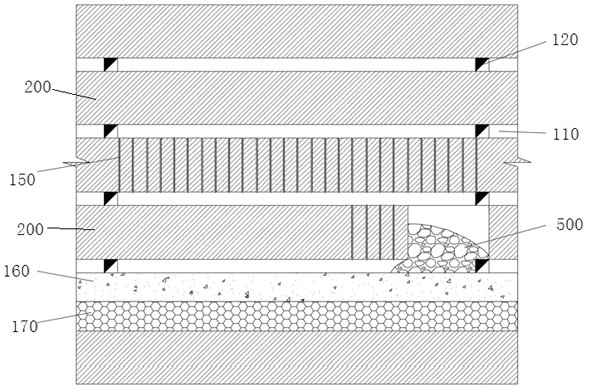

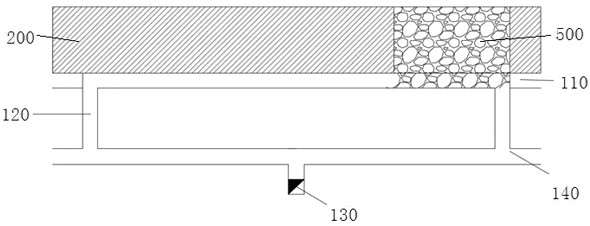

[0029] Such as Figure 1-4 As shown, a kind of gently inclined medium-thick orebody non-solid waste filling mining method based on ellipsoidal ore-drawing structure includes the following steps:

[0030] (1) First, divide the stages along the vertical direction of the ore body, leave the top and bottom pillars between the upper and lower stages, and the triangular bottom pillars of the upper stage and the triangular top pillars of the lower stage are combined to form the top and bottom pillars of the formation stage;

[0031] (2) Based on the well-known ellipsoid ore-drawing principle in the field, the stage is divided into subsections in the ore block, and the outline size of the triangle under each subsection is controlled to form an ore-collecting ditch for ore-drawing; at the same time, according to The nature of bulk ore drawing, determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com