A siloxane-terminated polyether lithium battery adhesive and preparation method thereof

A lithium battery, polyether type technology, applied in the direction of polyether adhesive, adhesive type, adhesive, etc., can solve the problems of difficult preparation of electrode composition, toxic organic solvent, environmental pollution, etc., and achieve good ion mobility and charge-discharge efficiency, fast reactivity, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

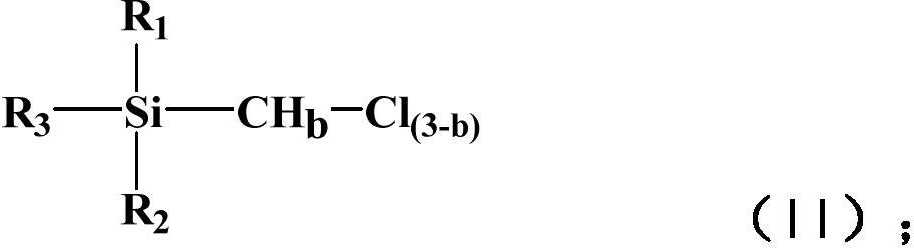

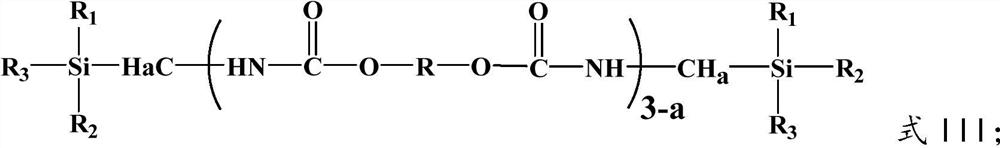

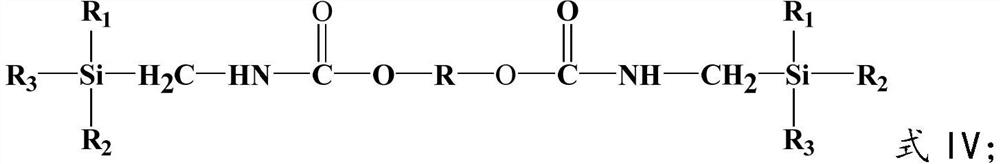

Method used

Image

Examples

Embodiment 1

[0037] First, add 9.0 g (0.11 mol) of potassium isocyanate, 20 g (0.27 mol) of DMF, and 0.16 g (0.06 mol) of KI into the dosage three-necked flask in sequence, raise the temperature to 70°C and continue stirring for 30 minutes to activate and evenly disperse; Next, the temperature was raised to 120°C, and 21.2 grams (0.1mol) of chloromethyltriethoxysilane and 100 grams (0.05mol) of polytetrahydrofuran ether (Mn=1000) were metered and dropped at the same time, respectively, and reacted at constant temperature for 7 hours. NMR nuclear magnetic detection-NCO group until the stoichiometric point is reached, the reaction is stopped, cooled to room temperature and filtered, and the filtrate is distilled to remove the solvent to obtain the siloxane-terminated polyether lithium battery adhesive.

Embodiment 2

[0039] First, add 9.0 g (0.11 mol) of potassium isocyanate, 20 g (0.27 mol) of DMF, and 0.16 g (0.06 mol) of KI into the dosage three-necked flask in sequence, raise the temperature to 75°C and continue stirring for 30 minutes to activate and evenly disperse; Next, the temperature was raised to 110°C, and 17.0 g (0.1 mol) of chloromethyltrimethoxysilane and 100 g (0.05 mol) of polytetrahydrofuran ether (Mn=1000) were metered and dropped at the same time, respectively, and reacted at constant temperature for 7 hours. NMR detection - NCO group until the stoichiometric point is reached, the reaction is stopped, cooled to room temperature and filtered, and the filtrate is distilled to remove the solvent to obtain the siloxane-terminated polyether lithium battery adhesive.

Embodiment 3

[0041] First, add 9.0 g (0.11 mol) of potassium isocyanate, 20 g (0.27 mol) of DMF, and 0.16 g (0.06 mol) of KI into a three-necked flask in sequence, raise the temperature to 100°C and continue stirring for 30 minutes to activate and evenly disperse; Next, the temperature was raised to 90°C, and 18.2 grams (0.1mol) of chloromethyldiethoxymethylsilane and 100 grams (0.05mol) of polytetrahydrofuran ether (Mn=1000) were metered and dropped at the same time, and reacted at a constant temperature for 7 hours. C-NMR nuclear magnetic detection -NCO group until the stoichiometric point is reached, the reaction is stopped, cooled to room temperature and filtered, and the filtrate is distilled to remove the solvent to obtain the siloxane-terminated polyether lithium battery adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com