Preparation method and application of pH-response-type high-strength conductive hydrogel

A conductive hydrogel, high-strength technology, applied in the direction of medical preparations of non-active ingredients, pharmaceutical formulas, and diseases transmitted by vectors, can solve problems such as long reaction time, many cross-linking agents, and cumbersome processes, and achieve The effect of short preparation time, fast gelation speed and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

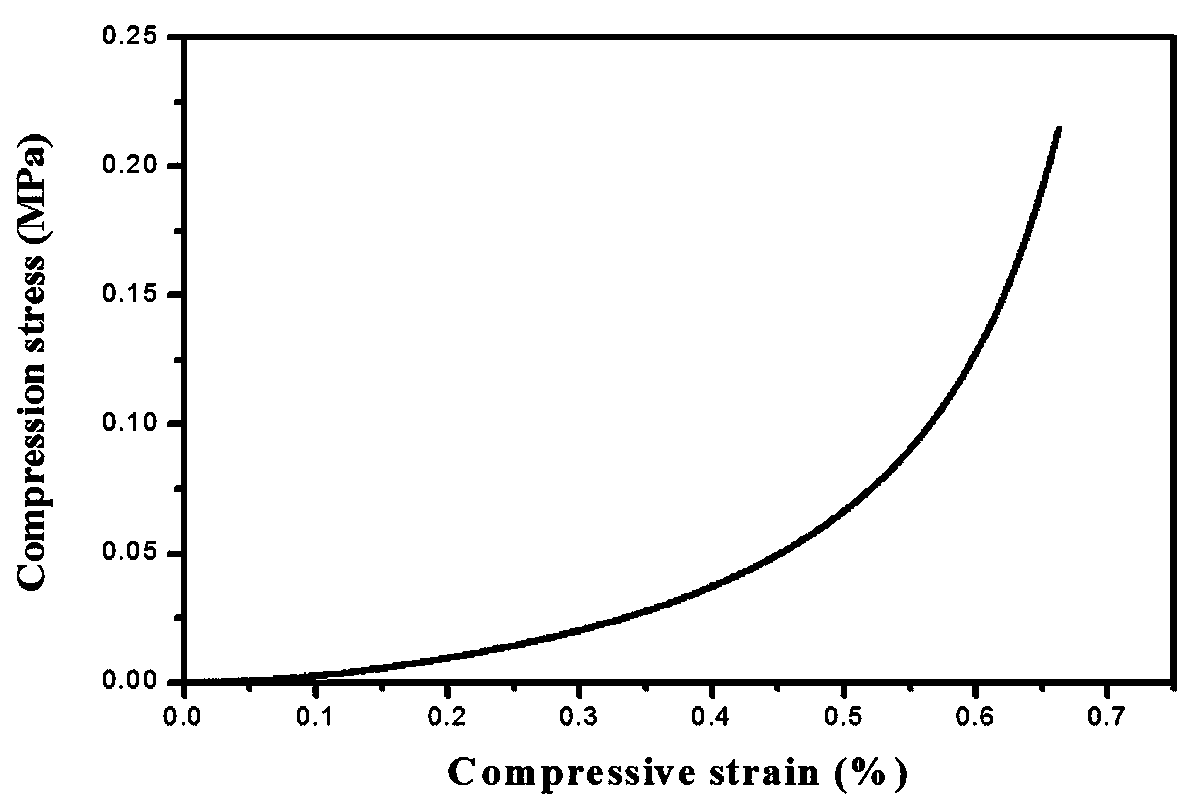

[0030] Weigh 1g of γ-PGA powder and dissolve it in 10mL of ultrapure water. The molecular weight of γ-PGA is 200,000-2 million units. Use magnetic stirring for 2-3 hours to make it dissolve uniformly, and then add 1mL of GPTMS as a reactive cross-linking agent. Use magnetic stirring for 3-4 hours to obtain a clear translucent liquid, then add 4 mL of hydrolyzed tetraethyl orthosilicate (TEOS) clear and transparent solution with a mass content of 50%, and put the reaction solution in an oven at 37°C for 2-4 hours to obtain Hydrogels. figure 1 Hydrogel compression pictures were prepared for the addition of 4 ml TEOS hydrolyzate. It can be seen that the shape of the hydrogel does not undergo plastic deformation after compression, and the strength of the hydrogel is relatively good. The prepared hydrogels were put into PBS (PBS, 8mL, pH7.4) DOX 50μM and TET 200μM solutions for 48h, and the soaked hydrogels were rinsed with PBS for 3 times, and the prepared pH=1.2, 7.4 Put 8mL of...

Embodiment 2

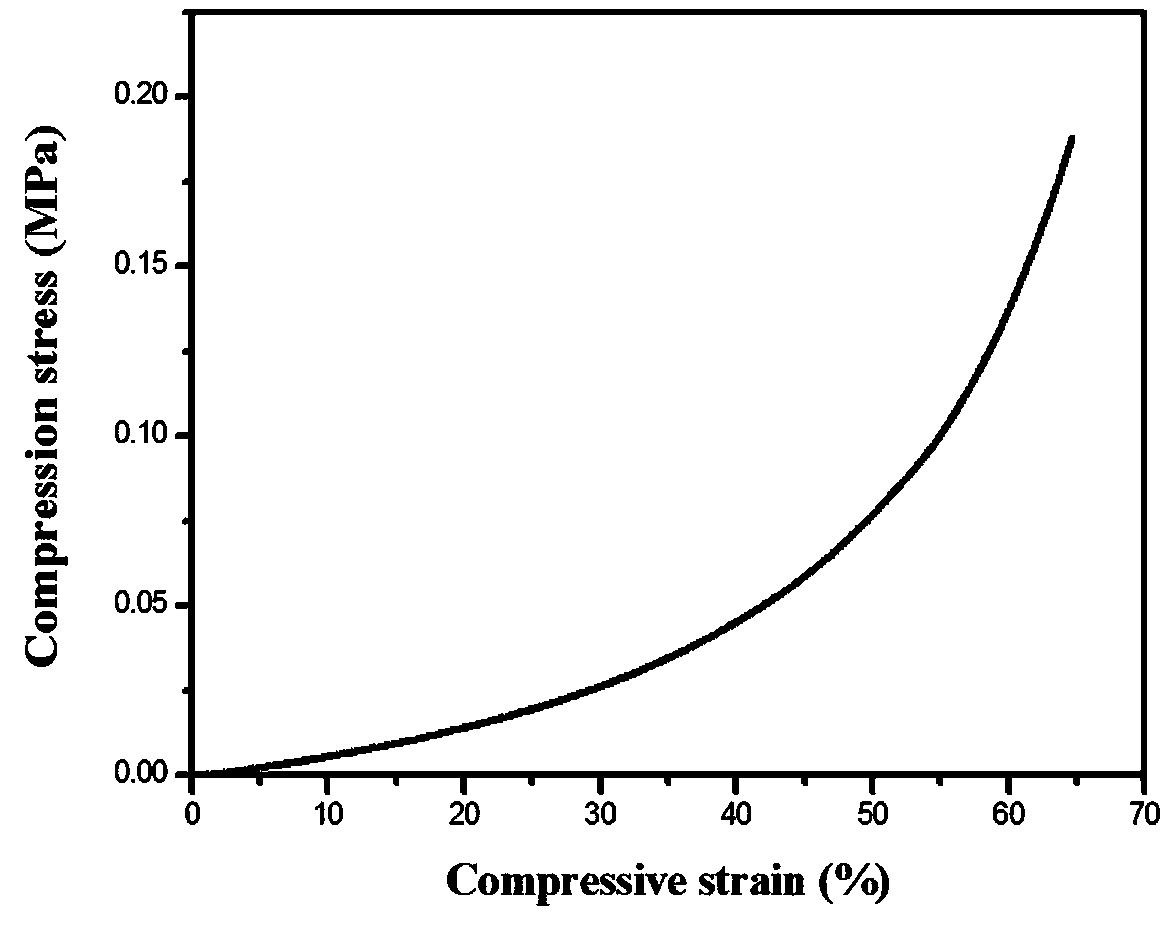

[0032] Weigh 1g of γ-PGA powder and dissolve it in 10mL of ultrapure water, stir it for 2-3 hours to make it uniform, then add 1mL of GPTMS as a reactive cross-linking agent, and stir it for 3-4 hours to obtain a clear translucent liquid, then Add 2 mL of a hydrolyzed tetraethyl orthosilicate (TEOS) clear solution with a mass content of 50%, and place the reaction solution in an oven at 37°C for 4-6 hours to obtain a hydrogel. figure 2 Hydrogel compression pictures were prepared for addition of 2 mL LTEOS hydrolyzate. It can be seen that the shape of the hydrogel after compression has not undergone plastic deformation. But the compressive stress of the hydrogel is not as good as that of the hydrogel in Example 1. The drug release experiment in Example 1 was repeated using the hydrogel prepared in Example 2.

Embodiment 3

[0034] A preparation method of pH-responsive high-strength conductive hydrogel is carried out in the following steps:

[0035] (1) Dissolve γ-polyglutamic acid in a beaker containing an aqueous solution at a mass concentration of 5wt%, place the beaker on a magnetic stirrer and stir evenly until it is completely dissolved to obtain an aqueous solution of γ-polyglutamic acid as the first A reaction solution; the molecular weight of γ-polyglutamic acid is 200,000-2 million units.

[0036] (2) Then slowly add γ-(2,3-glycidoxy)propyltrimethoxysilane to the first reaction solution while stirring, and stir evenly to obtain the second reaction solution; γ-(2, The mass ratio of 3-glycidoxy)propyltrimethoxysilane to the first reaction solution is 1:11;

[0037] (3) Mix and react ethyl orthosilicate with water to obtain a hydrolyzed aqueous solution of ethyl orthosilicate; during hydrolysis, the mass ratio of ethyl orthosilicate to water is 1:1, and at the same time add 0.1% of the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com