an injection molded structure

A cavity and bottom surface technology, applied in the field of injection molding structure, can solve the problems of great influence on product accuracy and quality, large deformation of injection molding cavity, small product structure size, etc., achieving low processing difficulty, ensuring continuity, and small impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

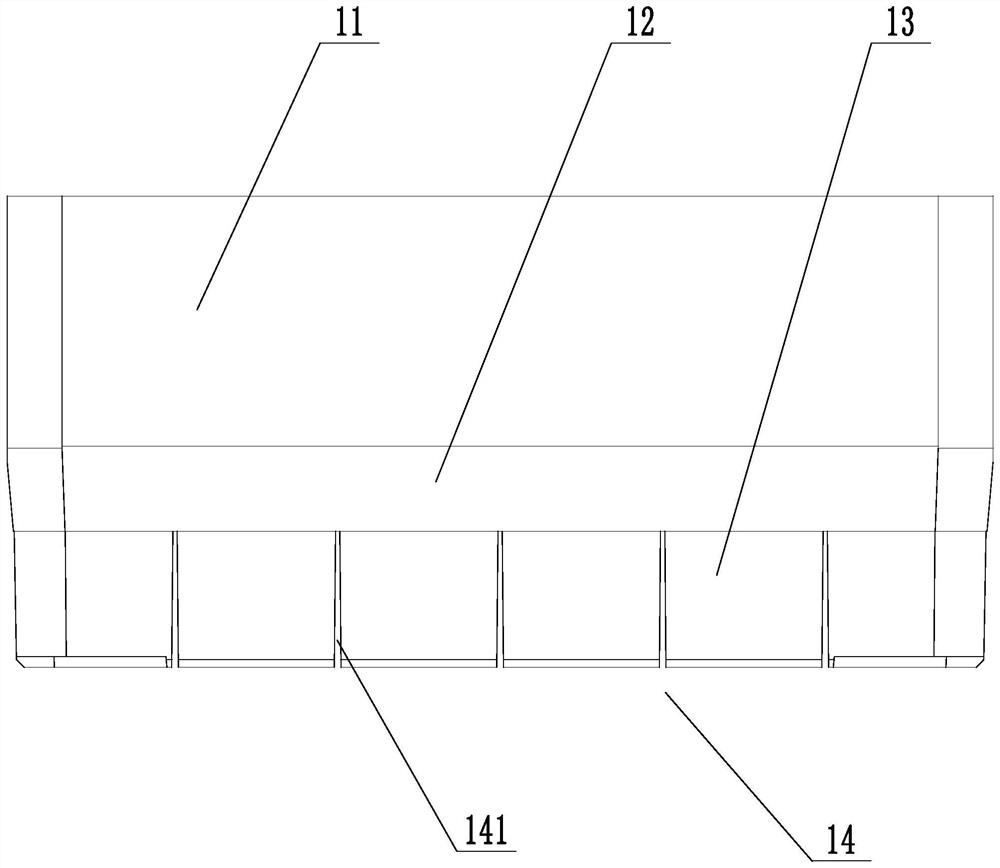

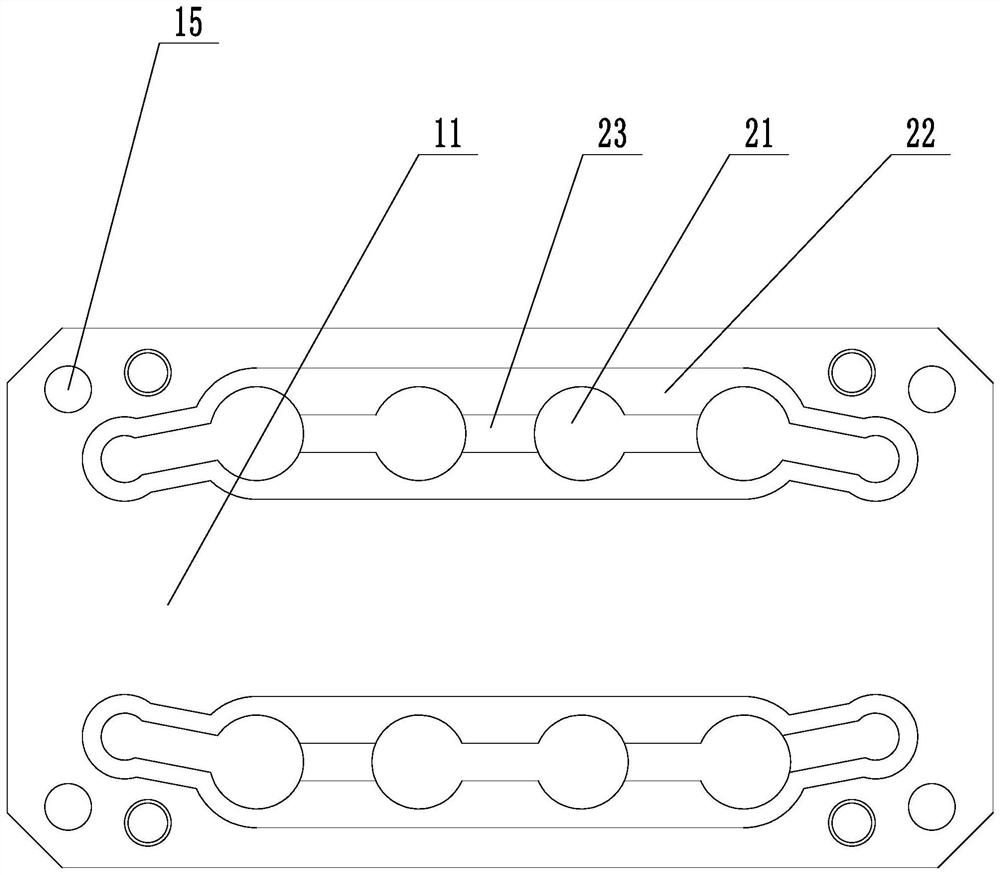

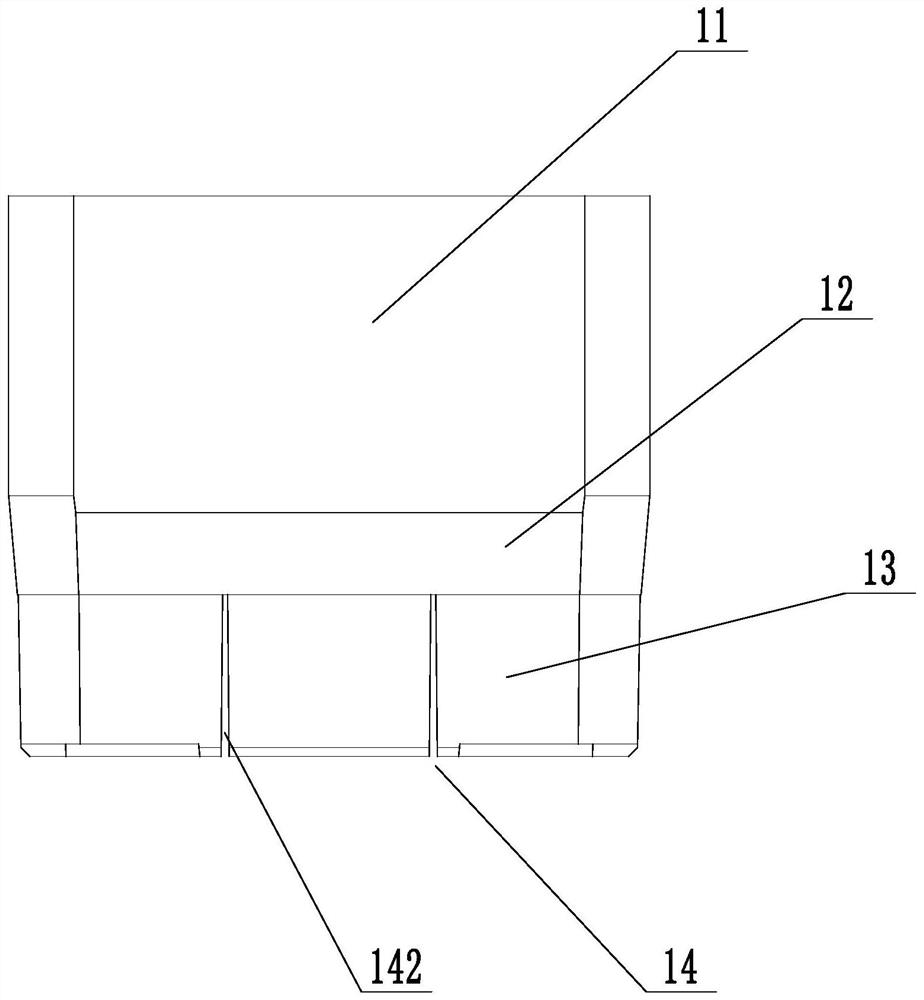

[0050] refer to figure 1 , is an injection molding structure disclosed in the embodiment of the present invention. The injection molding structure is used for the production of injection molded parts. Its main body is composed of a total of three parts: the first part 11, the second part 12 and the third part 13, wherein the first part 11 and The third part 13 is respectively fixed on the top surface and the bottom surface of the second part 12. For the sake of clarity of description, it is stipulated that the third part 13 is below, the second part 12 is in the middle, and the first part 11 is above, that is, the third part 13 is at the bottom. A part 11, a second part 12 and a third part 13 are arranged sequentially from top to bottom.

[0051] The first part 11 , the second part 12 and the third part 13 are integrally formed, that is, the three parts are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com