Modified liposome and composition, and preparation methods and applications of modified liposome and composition

A liposome composition and liposome technology, applied in the directions of botanical equipment and method, application, animal repellent, etc., can solve the problem of unfavorable medicinal liquid deposition, poor conduction effect, poor vesicle stability, etc. problems, to achieve good conduction effect, excellent field control effect, and good vesicle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

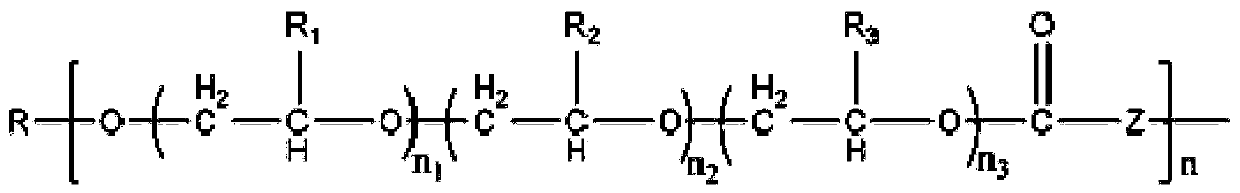

Method used

Image

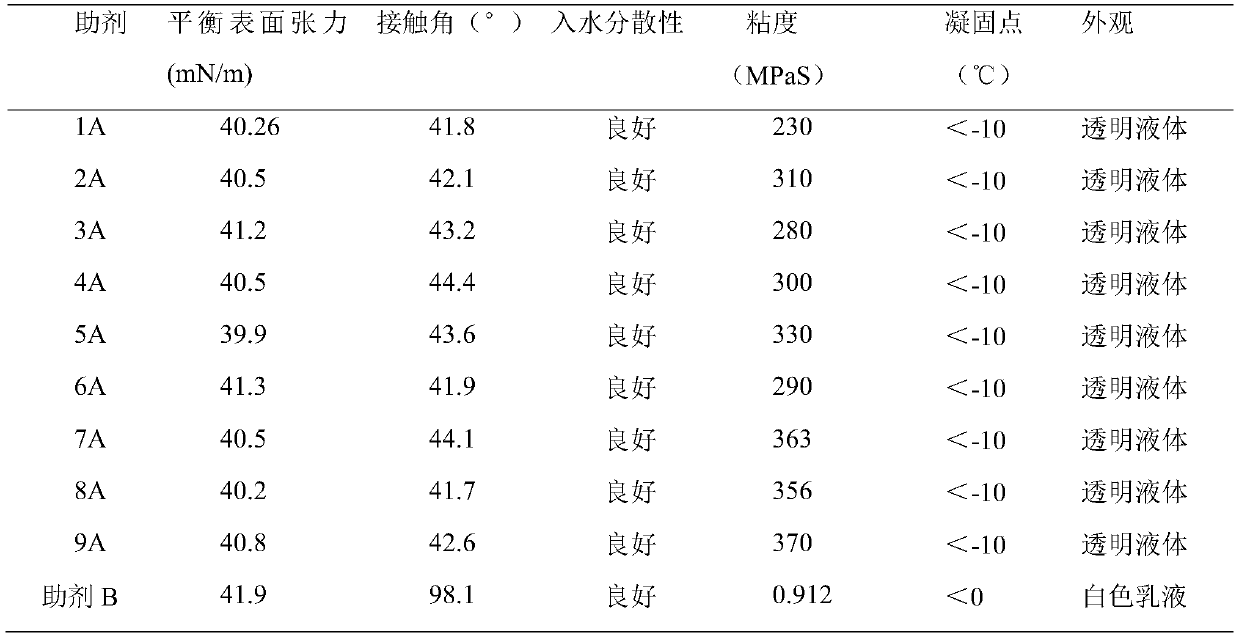

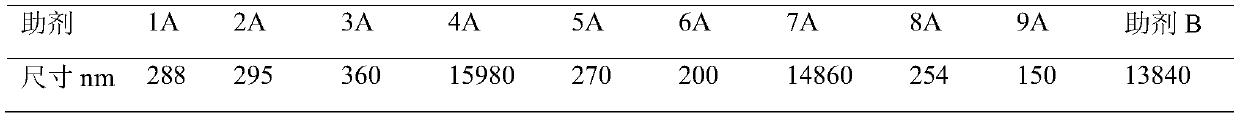

Examples

Embodiment 1

[0038] The preparation method of the modified liposome in the present embodiment, comprises the following steps:

[0039] 835g soybean oil containing 10% phospholipids, 130g cholesterol, 25g glycerol, 10g diethanolamine, 6.78g KOH (catalyst) were put into an alkoxylation reactor, and the nitrogen was replaced three times. Raise the temperature to 95-105°C for dehydration for 1 hour, then control the temperature to 120-150°C, feed 1261g of ethylene oxide (EO), control the feed temperature at 100-150°C, and the maximum feed pressure is less than 0.4MPa; the feed is completed . Curing at 120-150°C, when the curing pressure is close to 0.02MPa, nitrogen gas is introduced to keep the pressure at 0.15-0.25MPa. When the pressure in the reactor remains constant, the reaction ends; the aging time is about 1-2 hours. At 120-135°C, vacuumize for 0.5-1h, cool down to 70-80°C, add neutralizing reagent HAc to adjust the pH to 5-7. After the reaction is finished, the modified liposome pro...

Embodiment 2

[0045] Put 835g soybean oil containing 30% phospholipids, 130g cholesterol, 25g glycerol, 10g diethanolamine, and 6.78g KOH into an alkoxylation reaction kettle, and replace nitrogen three times. Raise the temperature to 95-105°C for dehydration for 1 hour, then control the temperature to 120-150°C, feed 1261g of EO, control the feed temperature at 100-150°C, and the maximum pressure of the feed is less than 0.4MPa; the feed is complete. Curing at 120-150°C, when the curing pressure is close to 0.02MPa, nitrogen gas is introduced to keep the pressure at 0.15-0.25MPa. When the pressure in the reactor remains constant, the reaction ends; the aging time is about 1-2 hours. At 120-135°C, vacuumize for 0.5-1h, lower the temperature to 70-80°C, add neutralizing reagent phosphoric acid to adjust the pH to 5-7. After the reaction is finished, the modified liposome product is obtained, and the sample is recorded as example 2.

[0046] Weigh 89.2g of the sample of Example 2, together ...

Embodiment 3

[0048] Put 835g soybean oil containing 50% phospholipids, 130g cholesterol, 25g glycerol, 10g diethanolamine, and 6.78g KOH into an alkoxylation reaction kettle, and replace nitrogen three times. Raise the temperature to 95-105°C for dehydration for 1 hour, then control the temperature at 120-150°C, feed 1261g of EO, control the feed temperature at 100-150°C, and the maximum pressure of the feed is less than 0.4MPa; the feed is complete. Curing at 120-150°C, when the curing pressure is close to 0.02MPa, nitrogen gas is introduced to keep the pressure at 0.15-0.25MPa. When the pressure in the reactor remains constant, the reaction ends; the aging time is about 1-2 hours. At 120-135°C, vacuumize for 0.5-1h, lower the temperature to 70-80°C, add neutralizing reagent phosphoric acid to adjust the pH to 5-7. After the reaction is finished, the modified liposome product is obtained, and the sample is recorded as example 3.

[0049] Weigh 89.2 g of the sample of Example 3, together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com