Method for improving impact power of JK55 steel grade oil well pipe by treating alloy steel with micro titanium

A technology of oil well pipe and alloy steel, which is applied in the field of seamless steel pipe manufacturing, can solve the problems of increased manufacturing cost of seamless steel pipes, and achieve the effects of low production cost, fine and uniform crystal grains, and uniform distribution of precipitates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

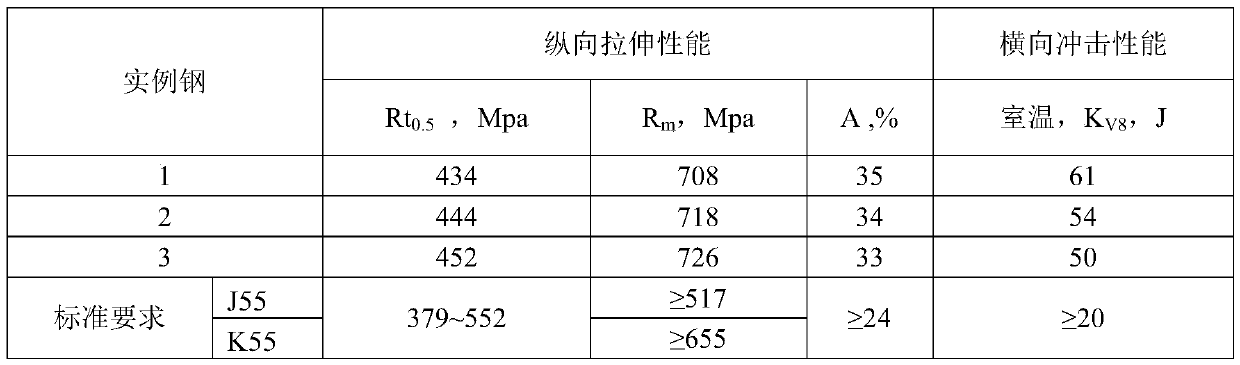

Examples

Embodiment

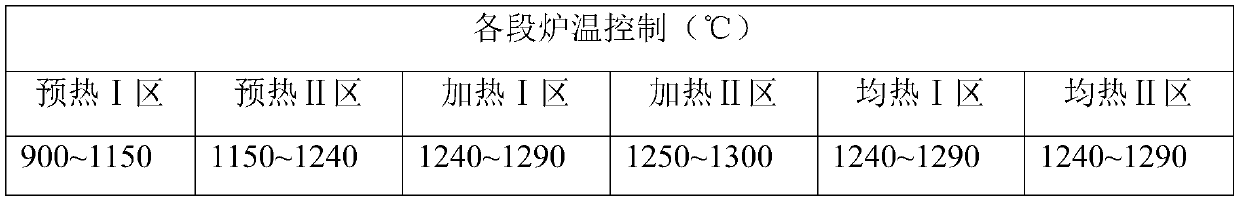

[0030] Hot rolling and forming: the temperature control of the billet in the preheating section, heating section and soaking section of the ring furnace is shown in Table 1.

[0031] Table 1 The temperature of each section of the round billet heating in the ring furnace

[0032]

[0033] The steel billet is heated to 1240℃~1290℃ in the ring furnace, and 1150℃~1210℃ is pierced into a capillary tube by a two-roll cross-rolling piercing machine, and then rolled into a waste tube through a 5-stand continuous mandrel rolling mill with a continuous rolling temperature of 1050. ℃~1160℃, and then heat sizing with 14 frame sizing and reducing machine, the outlet temperature of sizing is 830℃~900℃, and air cooling, sawing, straightening and flaw detection are carried out on a large cooling bed.

[0034] Pipe processing: steel pipe slitting, pipe end thread processing, steel pipe hydrostatic test, coupling screw connection, diameter, length measurement and weighing, spray marking, painting, sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com