Silk quilt with deinsectization mite-removal function and processing technology

A processing technology and technology for silk quilts, applied in the field of silk quilts, can solve problems such as poor insect and mite removal performance, and achieve the effects of avoiding poor tearing toughness and improving sleep quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

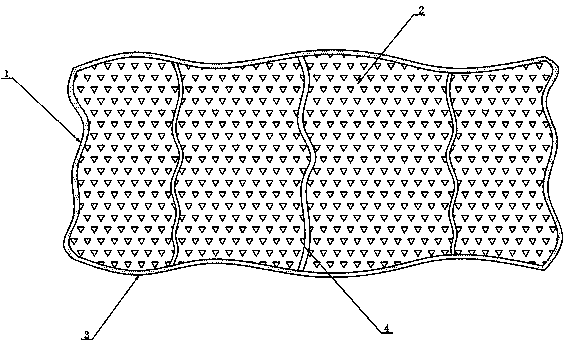

[0027] A silk quilt with the function of removing insects and mites, comprising a quilt body 1, the quilt body 1 includes a silk quilt body 2 and an external strip 3, the external strip 3 is arranged around the outside of the silk quilt body 2, and the silk quilt body The surface of the body 2 is evenly provided with a coating strip 4, which is arranged on the top surface and the bottom surface of the silk quilt body 2, and the external strip 3 and the coating strip 4 are all made of cotton, natural fibers and chemical fibers. become;

[0028] Each component in the external strip 3 and the covering strip 4 adopts the following proportioning according to the mass fraction: 22 parts of cotton, 14 parts of natural fiber, and 10 parts of chemical fiber;

[0029] The thickness of the external strip 3 is slightly larger than the thickness of the silk quilt 2, and the width of the covering strip 4 is set to 2-4cm.

[0030] The processing technology of the silk quilt specifically inc...

Embodiment 2

[0037] A silk quilt with the function of removing insects and mites, comprising a quilt body 1, the quilt body 1 includes a silk quilt body 2 and an external strip 3, the external strip 3 is arranged around the outside of the silk quilt body 2, and the silk quilt body The surface of the body 2 is evenly provided with a coating strip 4, which is arranged on the top surface and the bottom surface of the silk quilt body 2, and the external strip 3 and the coating strip 4 are all made of cotton, natural fibers and chemical fibers. become;

[0038] Each component in the external strip 3 and the covering strip 4 adopts the following proportioning according to the mass fraction: 28 parts of cotton, 18 parts of natural fiber, and 16 parts of chemical fiber;

[0039] The thickness of the external strip 3 is slightly larger than the thickness of the silk quilt 2, and the width of the covering strip 4 is set to 2-4cm.

[0040] The processing technology of the silk quilt specifically inc...

Embodiment 3

[0047] A silk quilt with the function of removing insects and mites, comprising a quilt body 1, the quilt body 1 includes a silk quilt body 2 and an external strip 3, the external strip 3 is arranged around the outside of the silk quilt body 2, and the silk quilt body The surface of the body 2 is evenly provided with a coating strip 4, which is arranged on the top surface and the bottom surface of the silk quilt body 2, and the external strip 3 and the coating strip 4 are all made of cotton, natural fibers and chemical fibers. become;

[0048] Each component in the external strip 3 and the covering strip 4 adopts the following proportioning according to the mass fraction: 25 parts of cotton, 17 parts of natural fiber, and 13 parts of chemical fiber;

[0049] The thickness of the external strip 3 is slightly larger than the thickness of the silk quilt 2, and the width of the covering strip 4 is set to 2-4cm.

[0050] The processing technology of the silk quilt specifically inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com