Preparation method of water supramolecular motor

A technology of molecular motors and water molecules, applied in electrostatic generators/motors, electrical components, electrostatic motors, etc., can solve problems such as small or negligible rotational barriers, high rotational potential barriers, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] A preparation method of a water supramolecular motor, comprising the steps of:

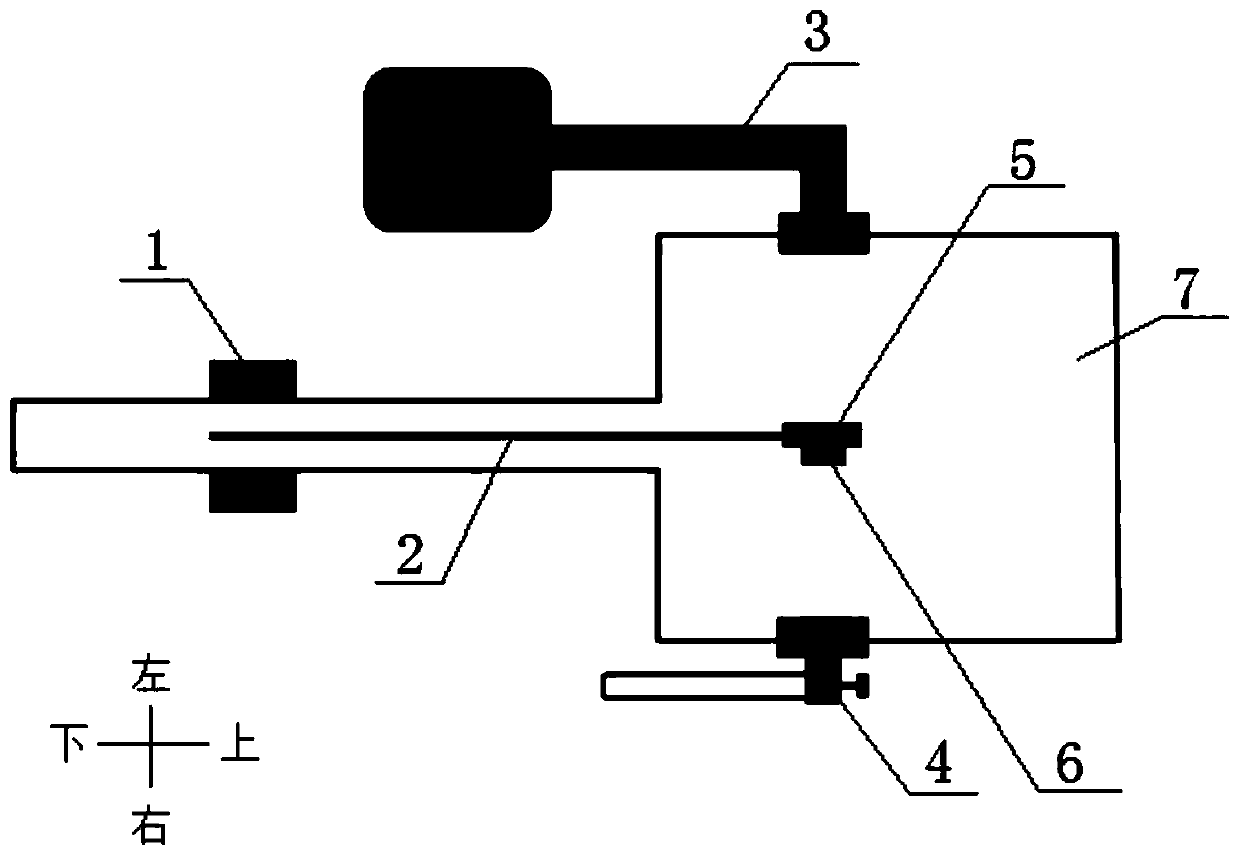

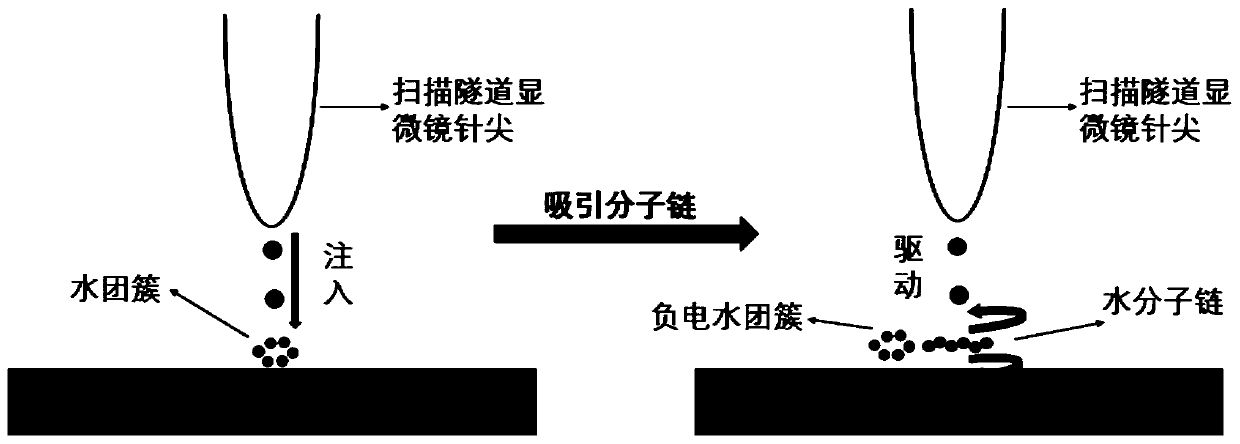

[0026] S1, see figure 1 , the device for preparing water clusters and water molecular chains by highly directional cracking graphite surface includes a magnetic handle 1, a magnetic sampling rod 2, a molecular pump 3, a micro-leakage valve 4, a sample seat 5, a sample 6 and a vacuum chamber 7, The magnetic handle 1 is arranged outside the vacuum chamber and connected to one end of the magnetic sample transfer rod 2, the other end of the magnetic sample transfer rod 2 is connected to the sample holder 5, and the sample holder 5 is used to fix the conductive metal plate 6, Entering or withdrawing from the vacuum chamber 7 is controlled by the magnetic sampling rod 2; the micro-leakage valve 4 is arranged on the right side of the vacuum chamber 7 for providing water molecules, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com