Method for improving optical switching frequency of GaN ultraviolet detector

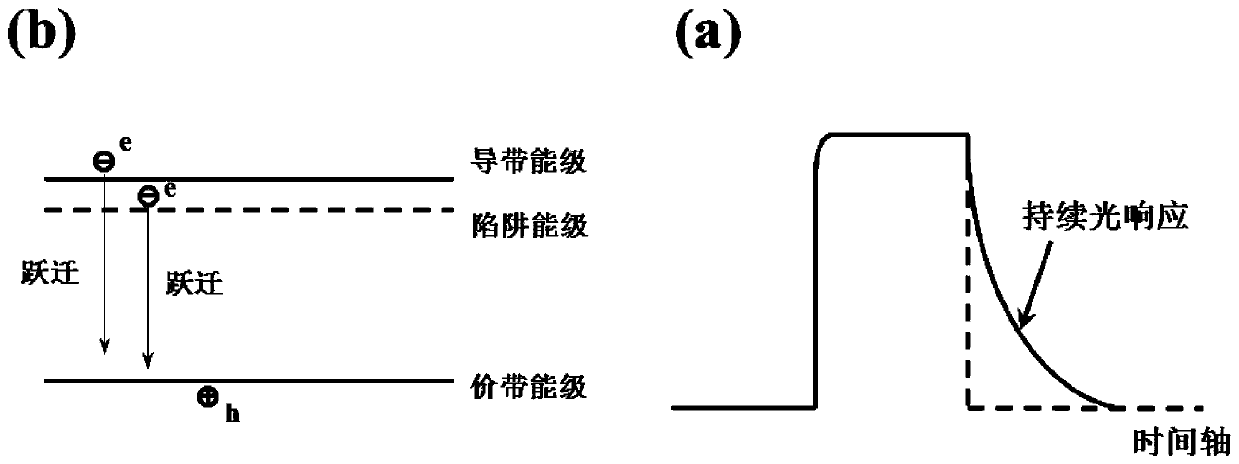

A technology of ultraviolet detector and optical switch, which is applied in the field of ultraviolet detection, can solve the problems of slow detector response time and switching frequency, cannot meet the fast response of GaN ultraviolet detector, and the carrier cannot be recombined immediately, so as to improve the switching frequency , high-sensitivity ultraviolet light detection, and the effect of improving the response frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

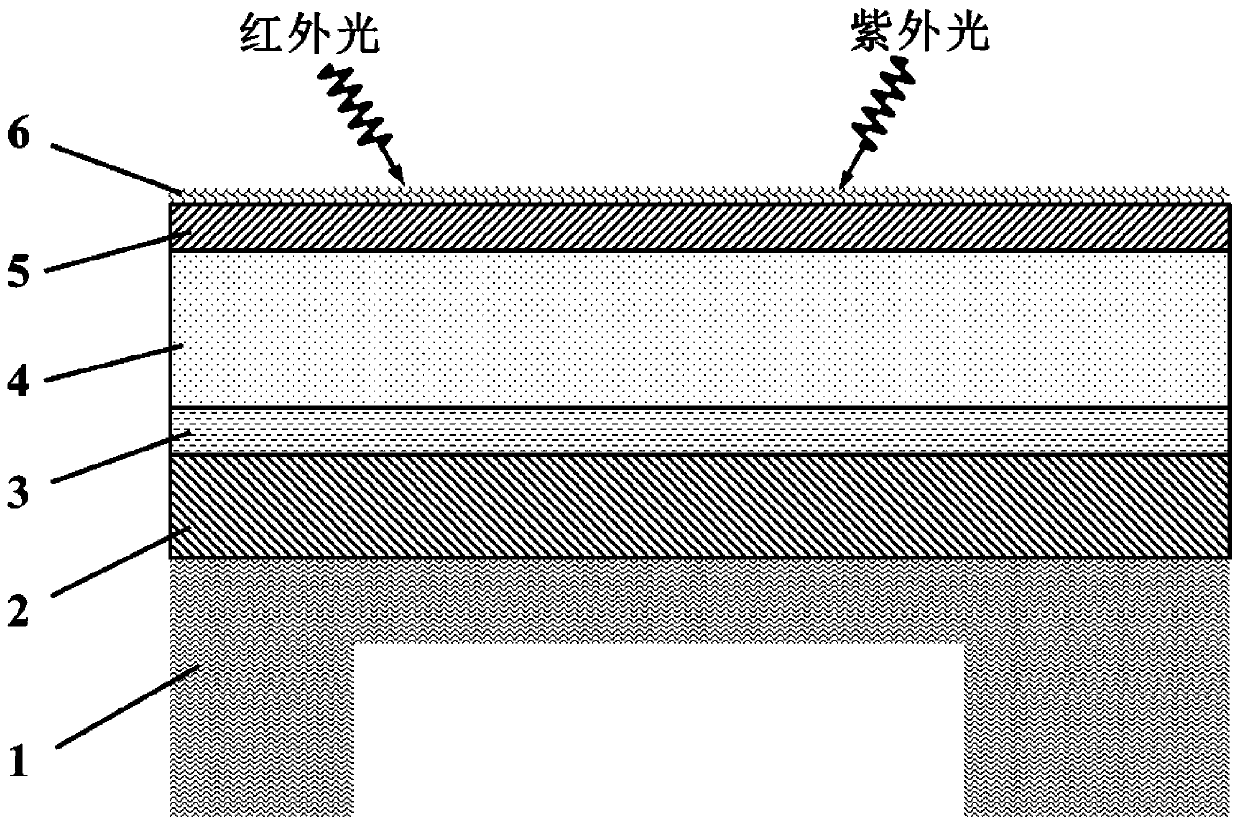

[0033] This implementation case provides a method for increasing the optical switching frequency of a GaN ultraviolet detector. The profile of the device is as follows figure 2 As shown, it consists of Si substrate 1, GaN buffer layer 2, n-type doped GaN layer 3, intrinsically doped GaN layer 4, p-type doped AlGaN layer 5 and SiO 2 Nanoparticles 6 Composition.

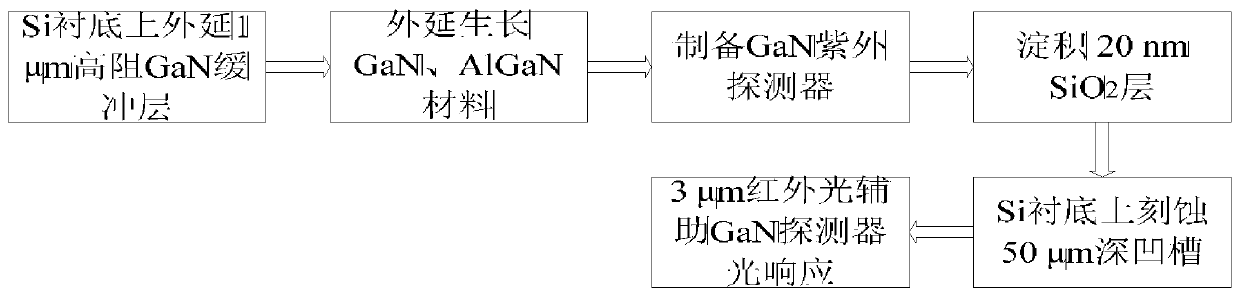

[0034] Such as image 3 As shown, the methods include:

[0035] 1) Sampling the substrate and pretreating its surface, and epitaxially growing a 1 μm high-resistance GaN buffer layer 2 on the substrate;

[0036] 2) On the high-resistance GaN buffer layer 2, epitaxially grow an n-type doped GaN layer, an intrinsic doped GaN layer and a p-type doped AlGaN layer in sequence to form an epitaxial layer;

[0037] 3) Patterning the epitaxial layer by photolithography, etching and other processes;

[0038] 4) Deposit 20nm thick SiO on the patterned epitaxial layer 2 nanoparticle layer 6;

[0039] 5) On the Si substrate ...

Embodiment 2

[0042] This implementation case provides a method to increase the optical switching frequency of GaN ultraviolet detectors. The specific preparation process is as follows Figure 4 shown, including:

[0043] 1) Sampling the substrate and pre-treating its surface, and epitaxially growing a 2 μm high-resistance GaN buffer layer 2 on the substrate;

[0044] 2) On the high-resistance GaN buffer layer 2, epitaxially grow an n-type doped GaN layer, an intrinsic doped GaN layer and a p-type doped AlGaN layer in sequence to form an epitaxial layer;

[0045] 3) Patterning the epitaxial layer by photolithography, etching and other processes;

[0046] 4) Deposit 80nm thick SiO on the patterned epitaxial layer 2 nanoparticle layer 6;

[0047] 5) On the Si substrate 1, selectively etch to prepare a thermal insulation groove, the groove depth is 150 μm;

[0048] 6) When detecting or testing ultraviolet light, use infrared light with a wavelength of 3.5 μm to irradiate the photosensitive...

Embodiment 3

[0050] The specific preparation process is as Figure 5 shown, including:

[0051] 1) The substrate is sampled and its surface is pretreated, and a 3 μm high-resistance GaN buffer layer 2 is epitaxially grown on the substrate.

[0052] 2) On the high-resistance GaN buffer layer 2, epitaxially grow an n-type doped GaN layer, an intrinsic doped GaN layer and a p-type doped AlGaN layer in sequence to form an epitaxial layer;

[0053] 3) Patterning the epitaxial layer by photolithography, etching and other processes;

[0054] 4) Deposit 180nm thick SiO on the patterned epitaxial layer 2 nanoparticle layer 6;

[0055] 5) On the Si substrate 1, selectively etch to prepare heat-insulating grooves, the depth of which is 250 μm;

[0056] 6) When detecting or testing ultraviolet light, use infrared light with a wavelength of 4.0 μm to illuminate the photosensitive surface of the GaN detector to assist in photoresponse testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com