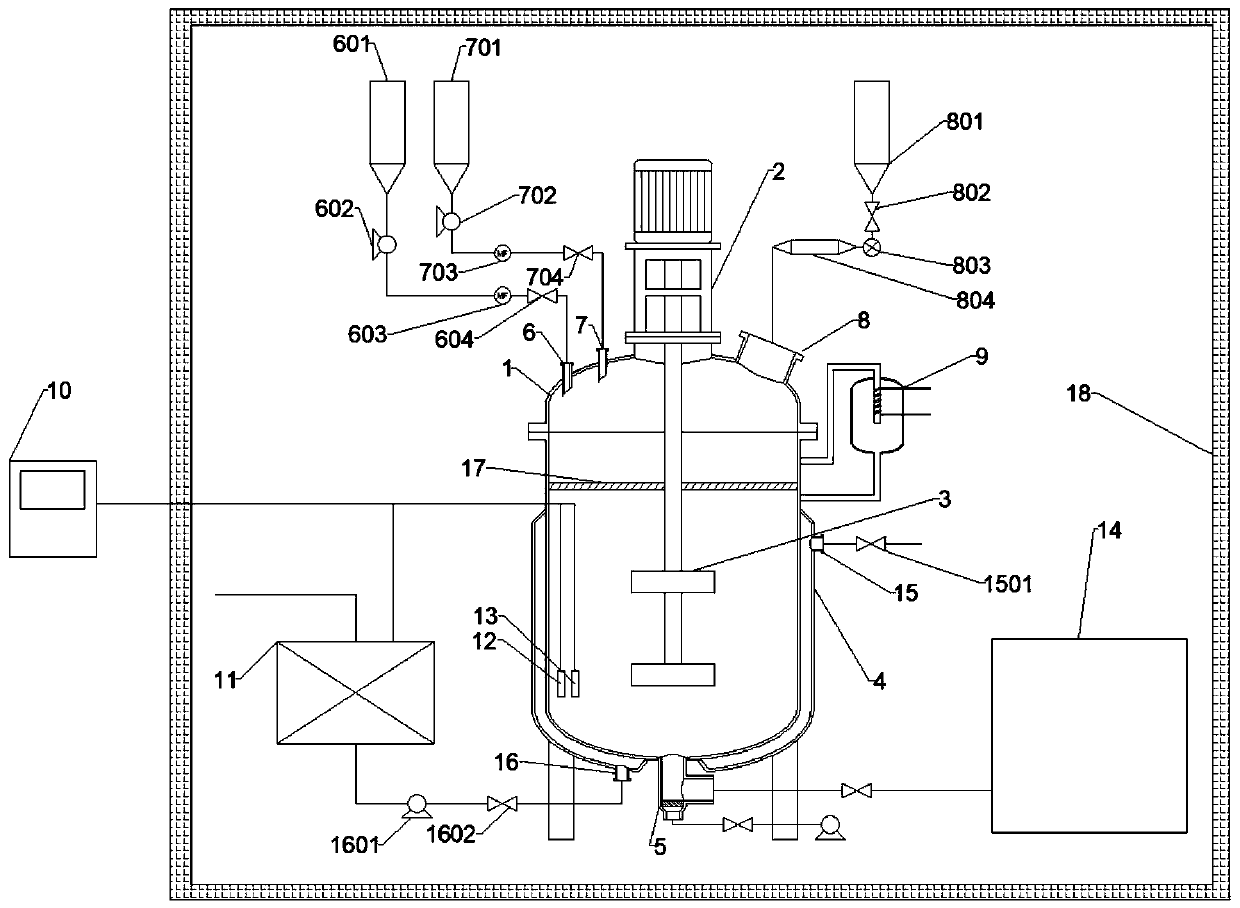

Reaction device and method for degrading radioactive waste resin based on Fenton method

A technology of radioactive waste resin and reaction device, which is applied in the fields of radioactive purification, chemical/physics/physicochemical stationary reactors, nuclear engineering, etc., can solve the problems of less research on devices, complex instruments and equipment, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

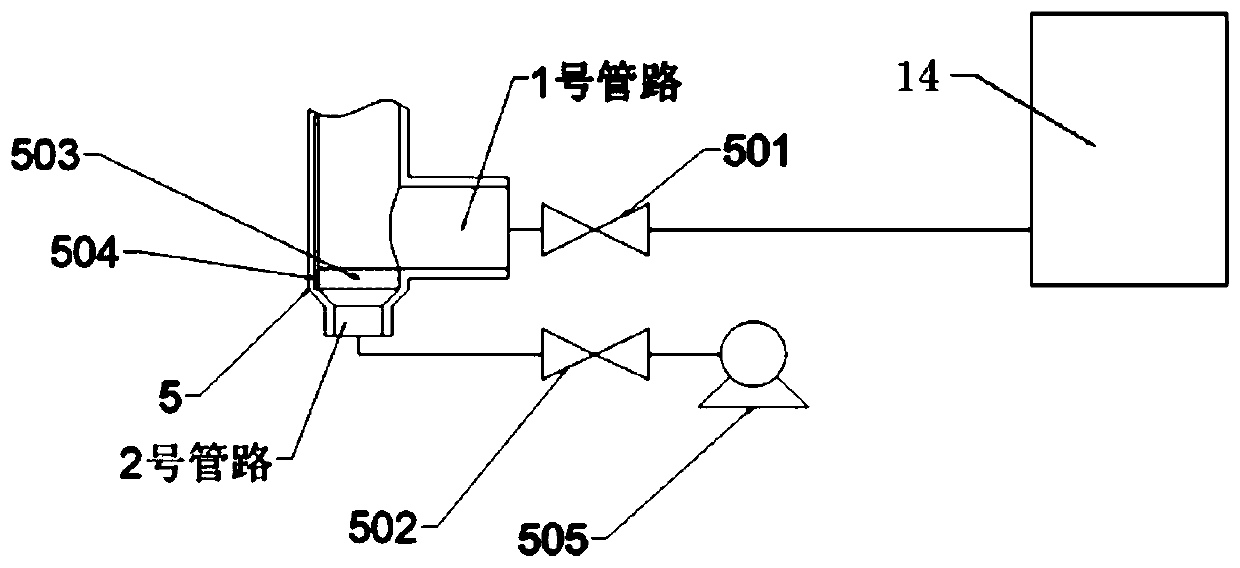

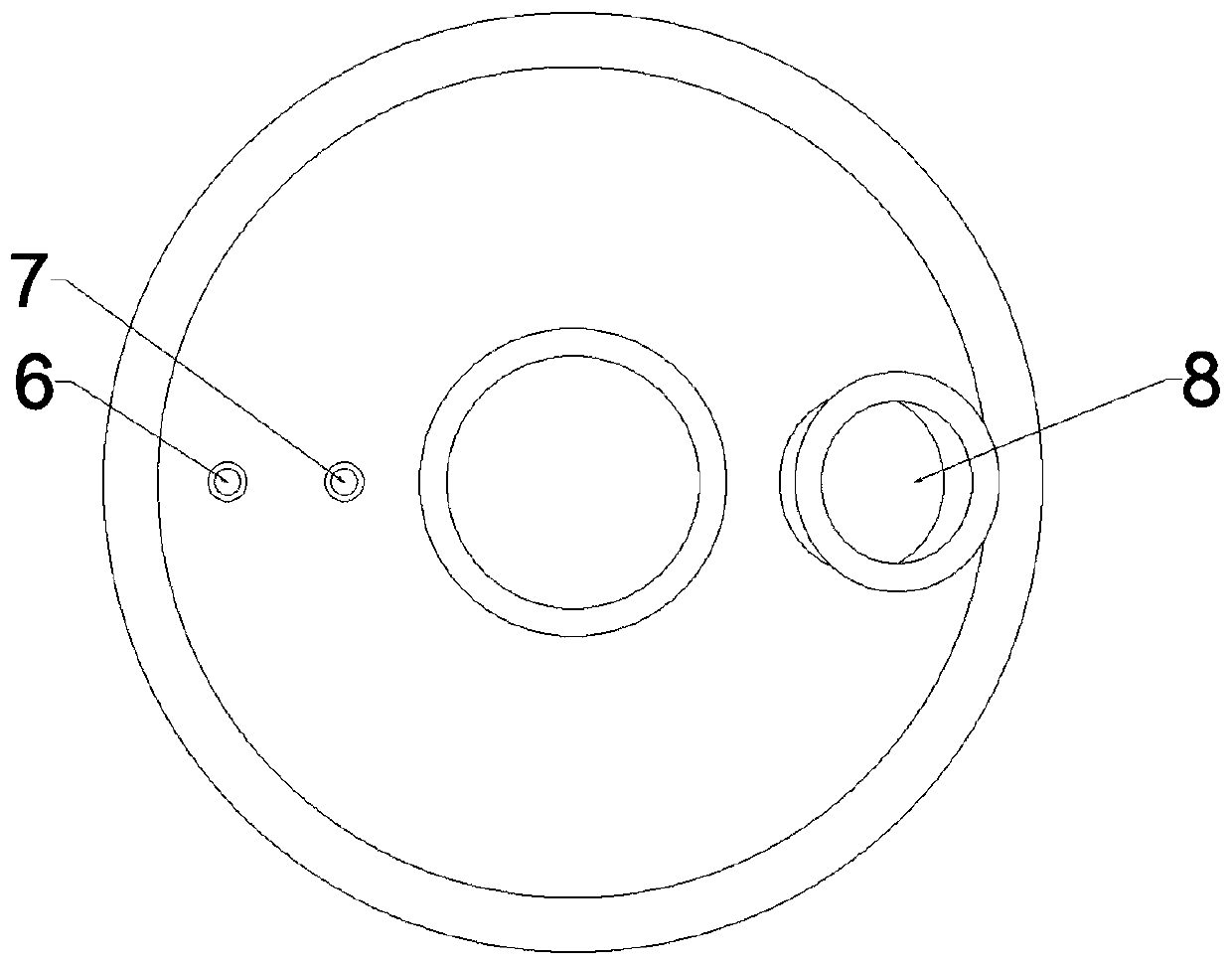

Method used

Image

Examples

Embodiment 1

[0050] Use the above-mentioned reaction device to process ZG C NR 50 strongly acidic cation exchange resin, the catalyst is Fe 2+ 、Cu 2 + 、Ce 3+ , Mn 2+ One or several in the solution, using H 2 SO 4 or HNO 3 Acidify the catalyst solution so that the catalyst is not easily oxidized before adding to the main body of the stirring tank, add 0.05~0.05mol / (L·g 干废树脂 ) of the acidifying catalyst solution to the acidifying catalyst feed port. Add 30% volume fraction of H 2 o 2 Solution 5~20ml / g 干废树脂 To the inlet of hydrogen peroxide, through the catalyst and H 2 o 2 The hydroxyl radicals (·OH) produced by the Fenton reaction oxidize and decompose the resin particles. The pH value in the reactor is controlled at 0-2, and the temperature is controlled at 60°C-99°C. After reacting for a certain period of time, the weight loss rate of the cation resin is 35% to 95%.

Embodiment 2

[0052] Adopt above-mentioned reaction device to process ZG A NR 170 strongly basic anion exchange resin, catalyst is Fe 2+ 、Cu 2 + 、Ce 3+ , Mn 2+ One or several kinds in the solution, add 0.1~0.3mol / (L·g 干废树脂 ) of H 2 SO 4 or HNO 3 Acidify the catalyst solution so that the catalyst is not easily oxidized before adding to the main body of the stirring tank, add 0.005~0.05mol / (L·g 干废树脂 ) of the acidifying catalyst solution to the acidifying catalyst feed port. Add 30% volume fraction of H 2 o 2 Solution 20~40ml / g 干树脂 To the inlet of hydrogen peroxide, through the catalyst and H 2 o 2 The hydroxyl radicals (·OH) produced by the Fenton reaction oxidize and decompose the resin particles. The pH value in the reactor is controlled at 0-1, and the temperature is controlled at 80°C-99°C. After reacting for a certain period of time, the weight loss rate of the anion resin is 20% to 60%.

Embodiment 3

[0054]The mixed resin of ZG C NR 50 strongly acidic cation exchange resin and ZG A NR 170 strongly basic anion exchange resin is treated by the above-mentioned reaction device, and the mass ratio is 1:1. The catalyst is Fe 2+ 、Cu 2+ 、Ce 3+ , Mn 2+ One or several kinds in the solution, add 0.05~0.2mol / (L·g 干废树脂 ) of H 2 SO 4 or HNO 3 Acidify the catalyst solution so that the catalyst is not easily oxidized before adding to the main body of the stirring tank, add 0.005~0.05mol / (L·g 干废树脂 ) of the acidifying catalyst solution to the acidifying catalyst feed port. Add 30% volume fraction of H 2 o 2 Solution 10~30ml / g 干废树脂 To the hydrogen peroxide inlet, through the catalyst and H 2 o 2 The hydroxyl radicals (·OH) produced by the Fenton reaction oxidize and decompose the resin particles. The pH value in the reactor is controlled at 0-1, and the temperature is controlled at 65°C-99°C. After reacting for a certain period of time, the weight loss rate of the mixed resin i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com