Cyclone desander for wellhead of oil field

A cyclone type and desander technology, applied in the field of desander, can solve the problems of high cost and long time, and achieve the effect of good sand removal effect, good sand removal effect and increased practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

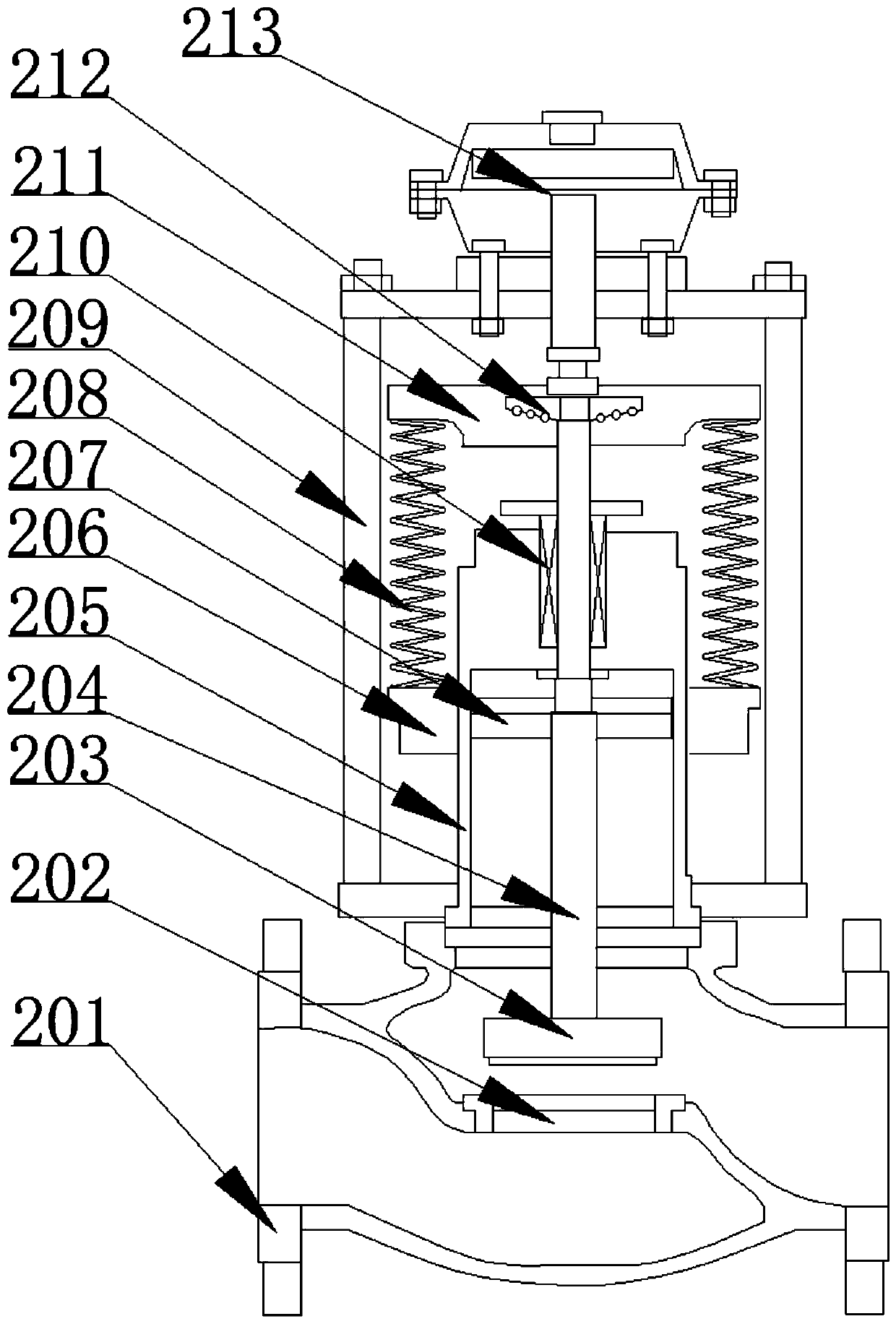

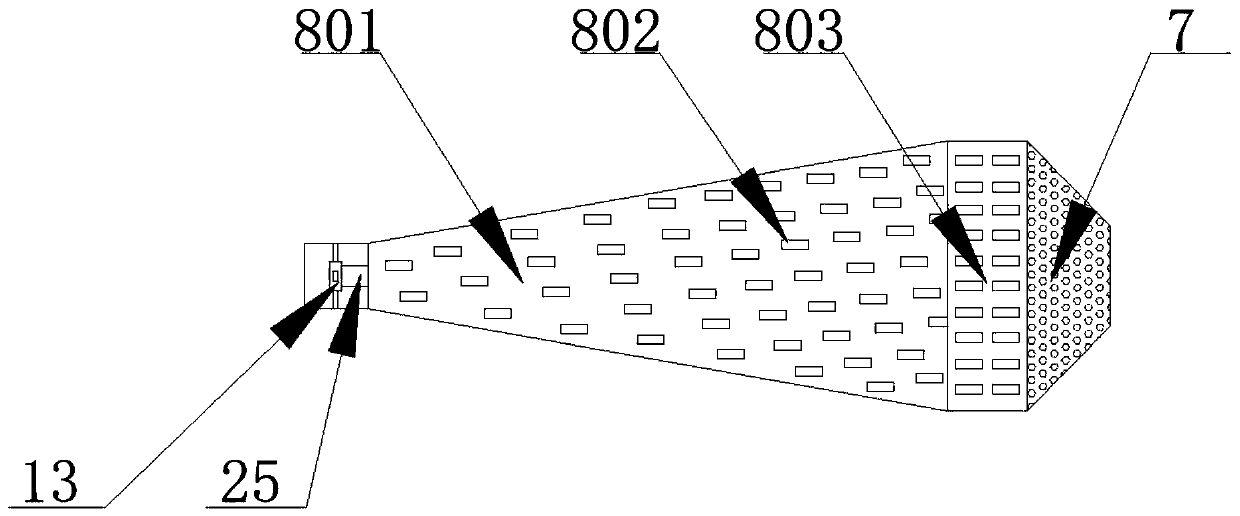

[0033] as attached Figure 1-4A cyclone desander for wellhead in an oil field is shown, which includes a bracket 1, a pressure regulating valve 2, a cylinder 3, a connecting screw 4, and a flange 5. The left end and the right end of the cylinder 3 have a liquid inlet and an outlet respectively. The liquid port, the pressure regulating valve 2, and the flange 5 are respectively fixedly installed on the liquid inlet and the liquid outlet of the cylinder 3 through the connecting screw 4. It is characterized in that: the connection between the pressure regulating valve 2, the flange 5 and the cylinder 3 A sealing ring 6 is provided, a connecting rod 14 is fixedly installed on the top of the bracket 1, and the top of the connecting rod 14 is fixedly installed under the flange 5, and the inside of the cylinder 3 is provided with a sand discharge cavity 9, and the inside of the cylinder 3 is fixed The sand discharge separation cylinder 8 is installed, the right end of the sand discha...

Embodiment 2

[0044] Concretely compared with embodiment 1: the appended reference manual Figure 7 As shown, one side of the cylinder 3 is provided with a liquid inlet, and the upper and lower ends of the cylinder 3 are respectively provided with a liquid outlet and a sand discharge port, and the sand discharge port of the cylinder 3 is provided with a communication hole 15, and the bottom of the cylinder 3 The end is preset with a screw, the screw at the bottom of the cylinder 3 has a matching connecting nut 16, the bottom of the cylinder 3 is fixedly installed with a connecting flange 17 through the connecting nut 16, and the bottom of the connecting flange 17 is fixedly installed with a valve 18 , the other end of the valve 18 is fixedly connected with a sand discharge flange 21, the sand discharge needle valve 20 is fixedly installed on both sides of the sand discharge flange 21, and the other end of the sand discharge needle valve 20 is provided with a sand discharge pressure gauge 19,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com