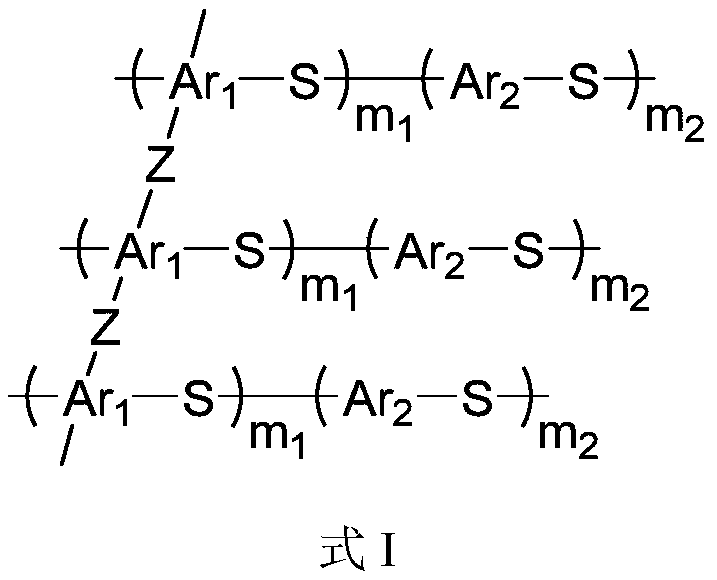

High-temperature-resistant corrosion-resistant two-dimensional polyarylene sulfide material with neutron absorption function, and preparation method thereof

A polyarylene sulfide and functional technology, which is applied in the field of two-dimensional polyarylene sulfide materials and their preparation, can solve the problems of lack of functionalization of the main chain structure and the lack of full use of special engineering plastic molecules, so as to enhance the ability to absorb neutrons. , the effect of strengthening the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

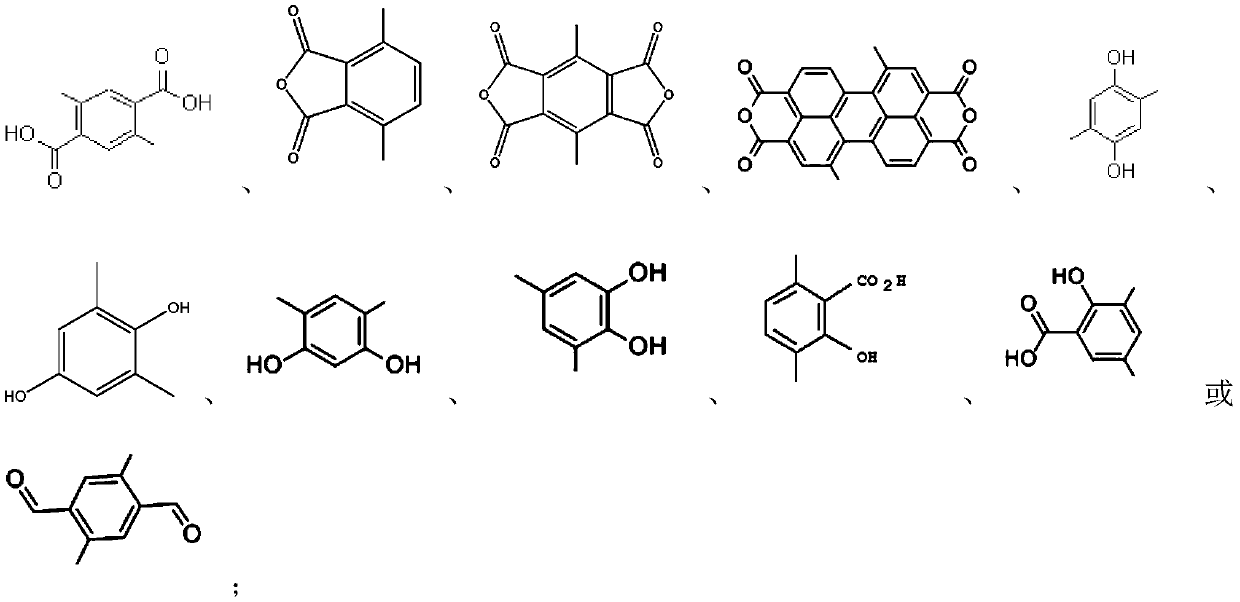

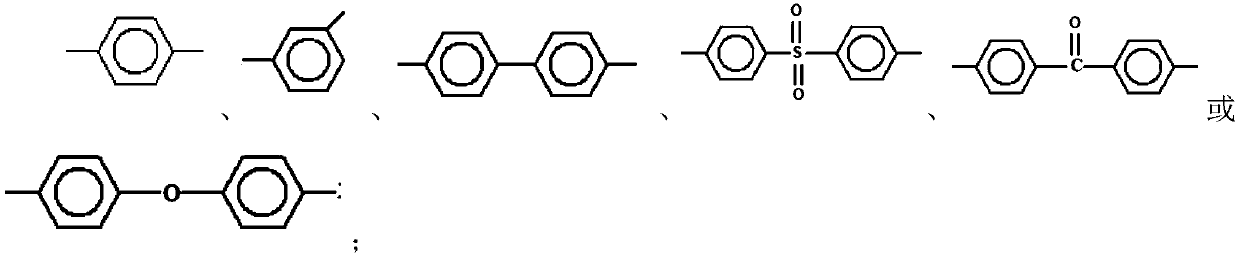

[0053] 1. Preparation of linear polyarylene sulfide (polyarylene sulfide containing active side groups) with active reactive side groups:

[0054] Add 2500ml NMP, 21gNaOH, 650g sodium sulfide, 50g trisodium EDTA, 58.76g 2,5-dichloroterephthalic acid into a 5L reactor Heated to 200°C under the protection of nitrogen, distilled 790ml of water, added 698.3g of p-dichlorobenzene, reacted at 220°C for 3 hours, the first stage reaction was completed; heated to 265°C for 3 hours, cooled to 120°C and slowly added deionized Water, filter, wash, dry at 110 DEG C for 24 hours, obtain white product 510g, productive rate is about: 92%, glass transition temperature is 95 DEG C, fusing point Tm=292 DEG C, intrinsic viscosity number: 0.36, melt index: 130g / 10min (molecular weight about 65,000).

[0055] 2. Preparation of two-dimensional polyarylene sulfide film raw material (polyarylene sulfide composite material with nuclear radiation protection function):

[0056] Disperse 105 g of poly...

Embodiment 2

[0058] 1. Preparation of linear polyarylene sulfide with reactive side groups:

[0059] Add 2500ml NMP, 21g NaOH, 650g sodium sulfide, 50g sodium citrate, 117.5g 2,5-dichloroterephthalic acid into a 5L reactor Heated to 200°C under the protection of nitrogen, distilled 790ml of water, added 661.5g of p-dichlorobenzene, reacted at 220°C for 3 hours, the first stage reaction was completed; raised the temperature to 265°C for 3 hours, cooled to 120°C and slowly added deionized Water, filter, wash, dry at 110 DEG C for 24 hours, obtain white product 520g, productive rate is about: 93%, glass transition temperature is 98 DEG C, fusing point Tm=296 DEG C, intrinsic viscosity number: 0.38, melting index: 125g / 10min (molecular weight about 68,000).

[0060] 2. Preparation of two-dimensional polyarylene sulfide film raw materials:

[0061] Disperse 105 g of polyarylene sulfide (PPSA) with 10% para-position (2,5) double pendant -COOH, which was dried in vacuum at 120°C for 4 hours, ...

Embodiment 3

[0063] 1. Preparation of linear polyarylene sulfide with reactive side groups:

[0064] Add 2500ml NMP, 21gNaOH, 650g sodium sulfide, 60g diethylenetriamine pentacarboxylate (DTPA), 44.75g 2,5-dichlorohydroquinone into a 5L reactor Heated to 200°C under the protection of nitrogen, distilled 790ml of water, added 698.3g of p-dichlorobenzene, reacted at 220°C for 3 hours, the first stage reaction was completed; raised the temperature to 265°C for 3 hours, cooled to 120°C and slowly added deionized Water, filter, wash, dry at 110 DEG C for 24 hours, obtain white product 510g, productive rate is about: 92%, glass transition temperature is 93 DEG C, fusing point Tm=292 DEG C, intrinsic viscosity number: 0.32, melt index: 145g / 10min (molecular weight about 60,000).

[0065] 2. Preparation of two-dimensional polyarylene sulfide film raw materials:

[0066] Disperse 112g of polyarylene sulfide (PPSA) with 5% para-(2,5) double pendant-OH groups after vacuum drying at 120°C for 4 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com