Natural gas ethane recycling method with high carbon dioxide adaptability

A technology with high carbon dioxide and recovery methods, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the lack of adaptability of carbon dioxide content, reduce the energy consumption of the natural gas ethane recovery device system, and reduce the energy consumption of the ethane recovery device system. consumption increase etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

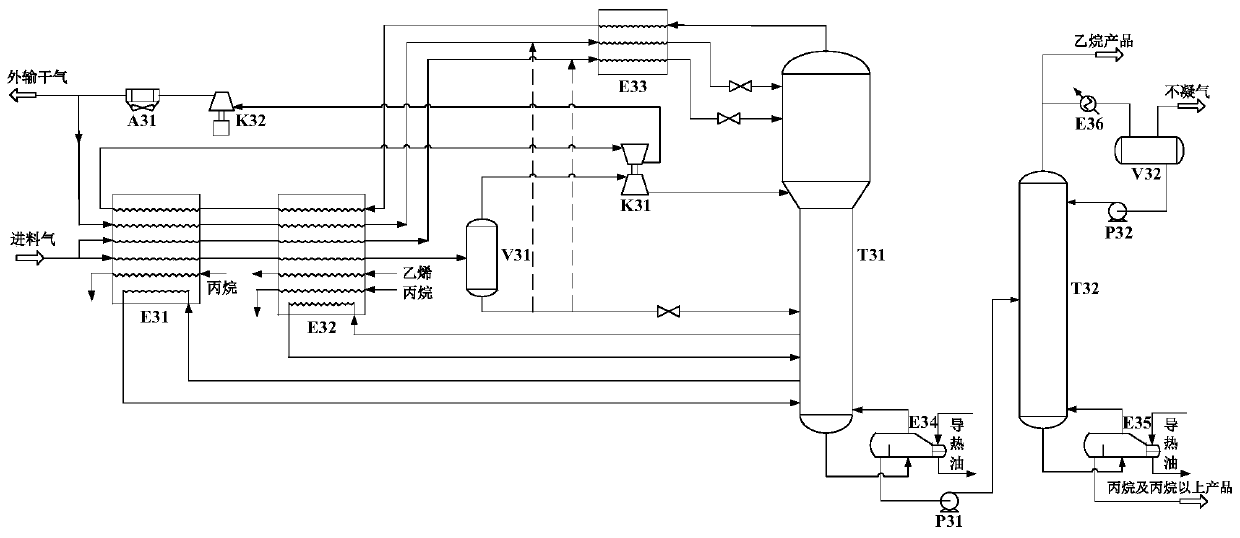

[0030] Such as image 3 As shown, the gas composition and working conditions of raw material gas (absolute pressure)

[0031] Raw gas processing scale: 500×10 4 m 3 / d

[0032] Raw gas pressure: 5.5MPa

[0033] Entry temperature: 38°C

[0034] Dry gas output pressure: ≥5.0MPa

[0035] The raw gas composition is shown in Table 1.

[0036] Table 1 Feed gas composition

[0037] components N 2

[0038] Such as image 3 As shown, the present invention discloses a natural gas ethane recovery method with high carbon dioxide adaptability. The raw material gas (5.5MPa, 38°C) entering the ethane recovery device is first divided into two parts, and enters the first cold box E31 and the second cold box simultaneously. The cold box E32 cools down, and after cooling, a part of the raw material gas enters the low-temperature separator V31, and the gas phase (5.46MPa, -58.0°C) is separated, and the gas-liquid mixture ( 2.65MPa, -87.04℃) into the middle and upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com