Fly ash sintering-expanded haydite, and energy-saving treatment method of fly ash

A treatment method and ceramsite technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of no added value, no return of benefits, and incomplete implementation, so as to save fuel costs, increase strength, and reduce weather conditions. The effect of gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

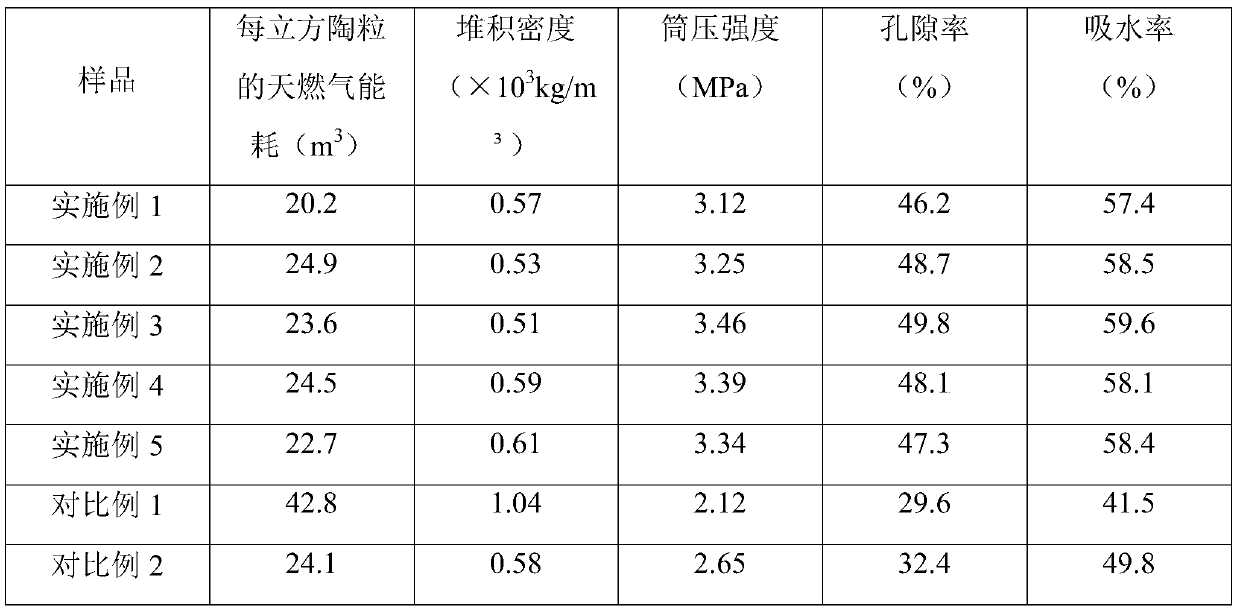

Examples

Embodiment 1

[0039] A kind of energy-saving treatment method of foundry dust removal of the present embodiment, comprises the following steps:

[0040] (1) Mix 40kg of clay and 45kg of dedusting ash, add 15kg of clear water and stir into mud;

[0041] (2) Extrude and granulate the mud to form raw meal balls, the size of the raw meal balls is set according to actual production needs, and the raw meal balls are heated from room temperature at a constant heating rate , the heating rate is 5°C / min, the first time the temperature is raised to 500°C, and the heat preservation treatment is 60 minutes, and the second heat treatment is continued to 1000°C, and the heat preservation is 60 minutes, and the high-temperature ceramsite sand after influx is cooled in the cooling pipeline. Cooling by air cooling, the generated hot air is collected and used to supplement the heat source in the front section to heat the heat source of raw meal balls, the cooled ceramsite enters the vibrating screen, the tem...

Embodiment 2

[0043] A kind of energy-saving treatment method of foundry dust removal of the present embodiment, comprises the following steps:

[0044] (1) Mix 50kg of shale and 32kg of dedusting ash, add 18kg of clear water and stir into mud;

[0045](2) Extrude and granulate the mud to form raw meal balls, the size of the raw meal balls is set according to actual production needs, and the raw meal balls are heated from room temperature at a constant heating rate , the heating rate is 6°C / min, the temperature is raised to 520°C for the first time, heat preservation treatment is 50 minutes, the temperature is raised to 1020°C for the second time, heat preservation is 50 minutes, and the high-temperature ceramsite sand after inflating is cooled in the cooling pipeline. Cooling by air cooling, the generated hot air is collected and used to supplement the heat source in the front section to heat the heat source of raw meal balls, the cooled ceramsite enters the vibrating screen, the temperatu...

Embodiment 3

[0047] A kind of energy-saving processing method of foundry dust removal ash of the present embodiment, comprises the following steps:

[0048] (1) Mix 30kg of sludge, 25kg of shale and 45kg of dedusting ash, add 20kg of clear water and stir into mud;

[0049] (2) Extrude and granulate the mud to form raw meal balls, the size of the raw meal balls is set according to actual production needs, and the raw meal balls are heated from room temperature at a constant heating rate , the heating rate is 7.5°C / min, the first time the temperature is raised to 550°C, the heat preservation treatment is 45min, the second heat treatment is continued to 1050°C, the heat preservation is 45min, and the high temperature ceramsite sand after inflow is cooled by the cooling pipeline. Cooling by air cooling, the generated hot air is collected and used to supplement the heat source in the front section to heat the heat source of raw meal balls, the cooled ceramsite enters the vibrating screen, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com