Production device of chemically strengthened glass

A technology for strengthening glass and production equipment, which is applied in the field of chemically strengthened glass production equipment, which can solve problems such as heat loss, uneven temperature, and poor product performance monitoring, and achieve the goals of increasing service life, ensuring heat preservation effect, and perfect interchangeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

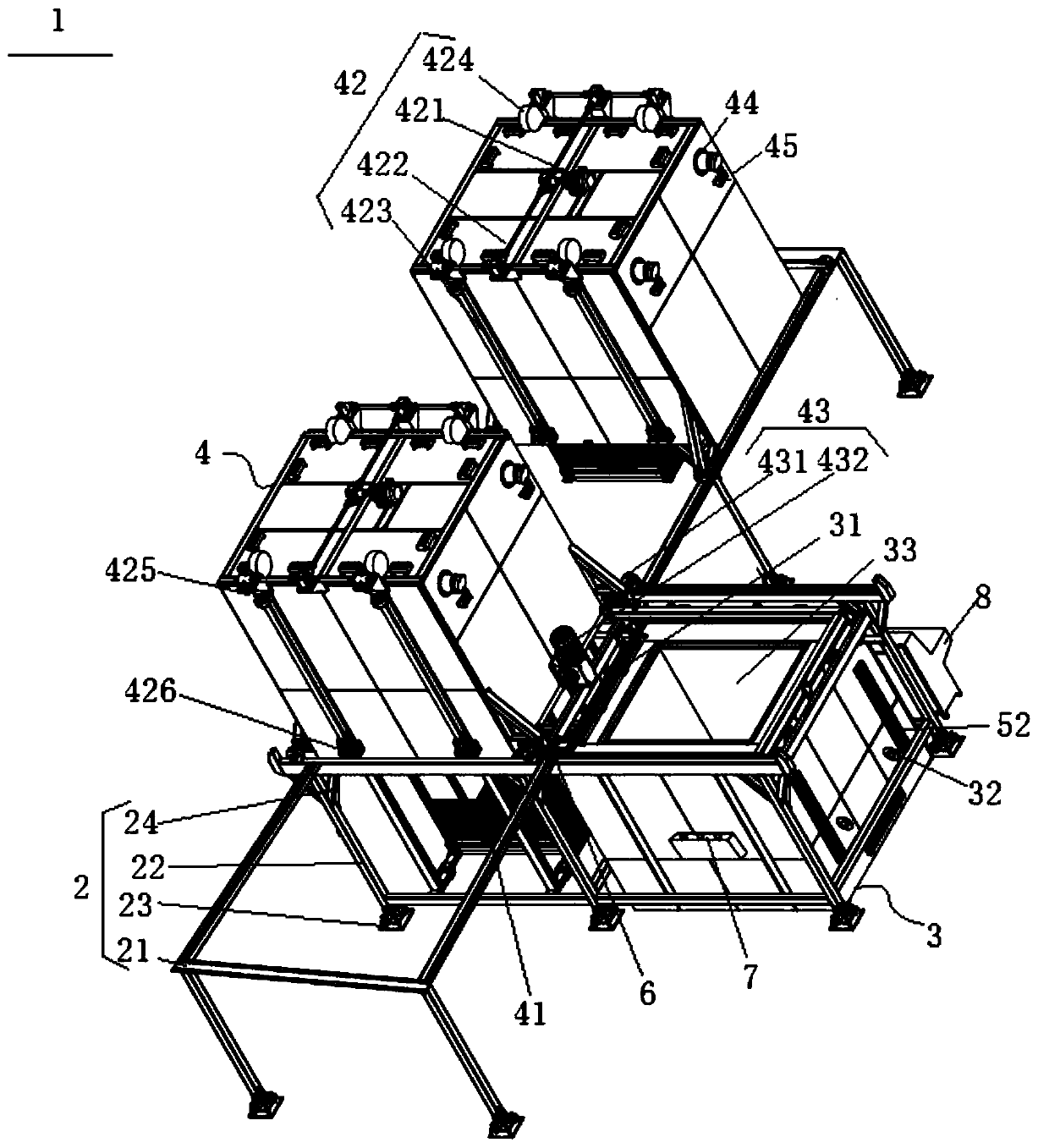

[0056] In an embodiment of the present invention, please refer to figure 1 , which shows a schematic structural view of a chemically strengthened glass production device 1 according to an embodiment of the present invention. The production device 1 of chemically strengthened glass is used for preheating and chemically strengthening glass. The production device 1 of chemically strengthened glass includes a support 2, a reaction box 3, a plurality of preheating boxes 4 and a plurality of heating devices 5, wherein:

[0057] The bracket 2 is mainly used to provide rigid support for multiple preheating boxes 4 . please refer again figure 1 The bracket 2 disclosed in this embodiment also includes an upper support frame 21, a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com