Adjustable multi-stage supercharged water jet nozzle

A technology of water jet and nozzle, applied in the direction of spray device, spray device, liquid spray device, etc., can solve the problem of insufficient water pressure of water jet, and achieve the effects of easy wear, expansion of range, and improvement of power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

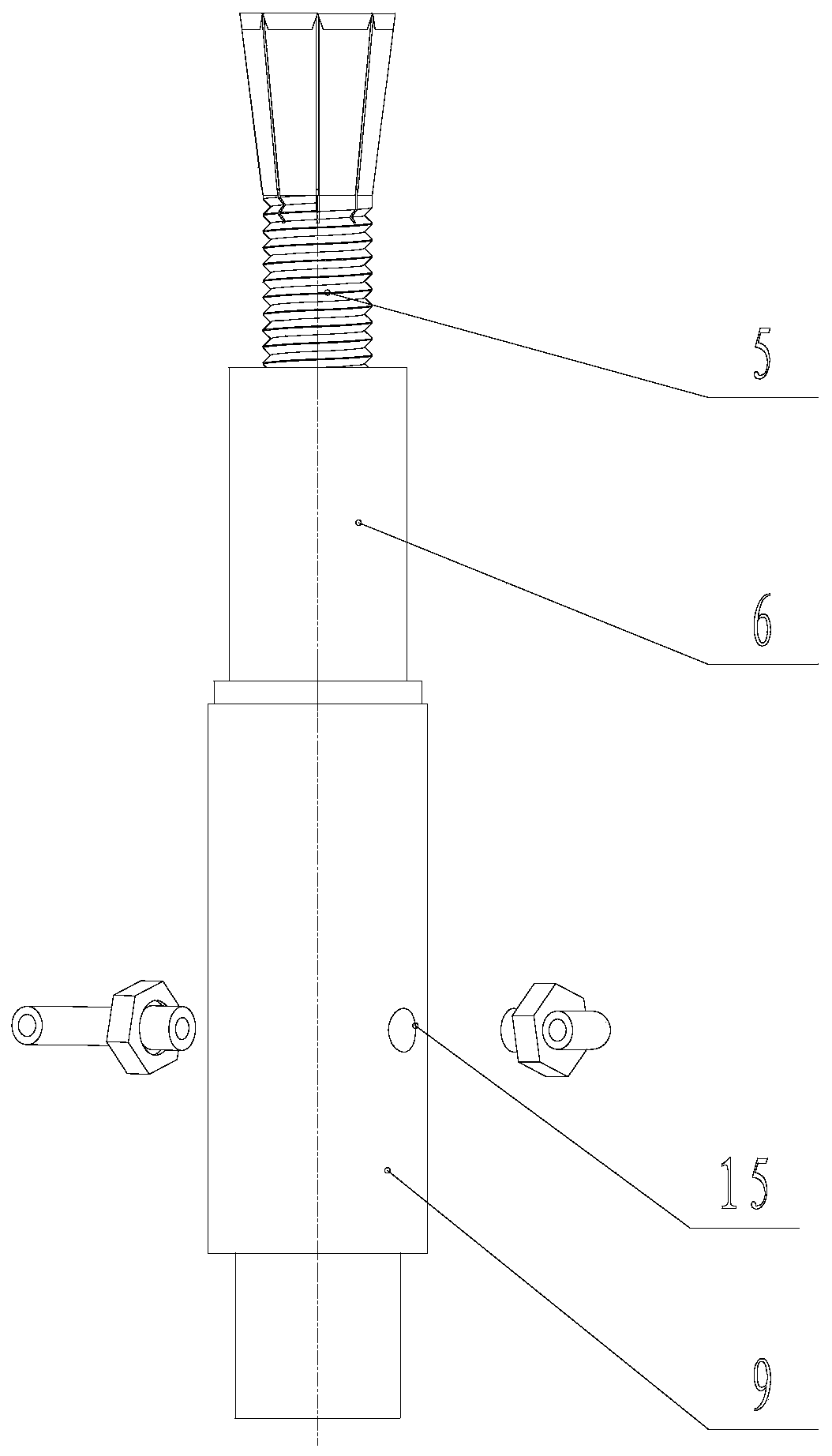

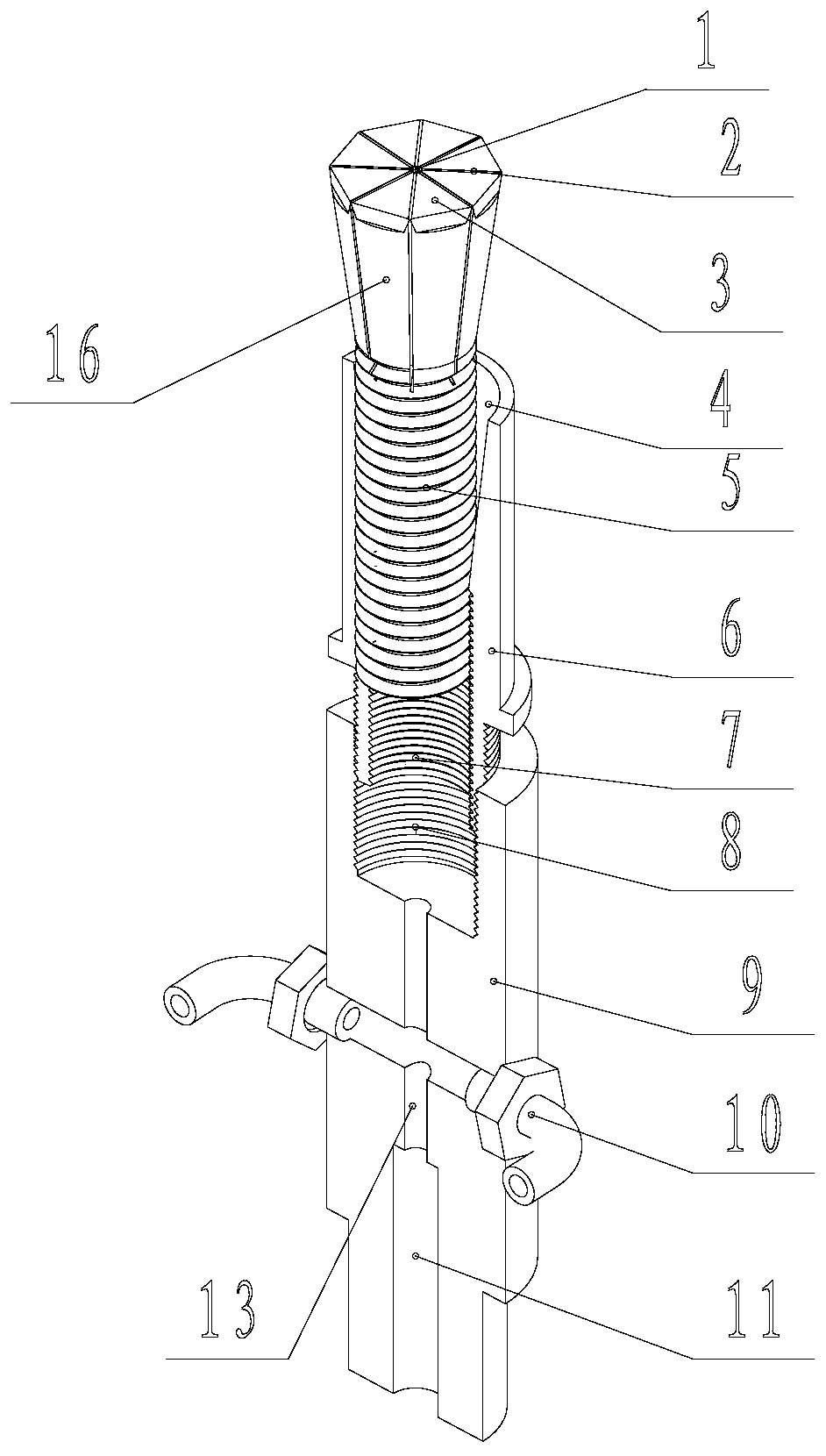

[0024] Figure 1~6 , including water jet nozzle 1, rubber sheet 2, nozzle core 3, inner cone surface of the inner cone sleeve 4, external thread part 5 at the tail end of the nozzle core, inner cone sleeve 6, internal thread 7 of the inner cone sleeve, Inner threads of the booster valve 8, booster valve body 9, high-pressure water pipe joint 10, booster valve main pipe hole 11, nozzle core adjustment and rotation outer corrugated surface 12, booster valve main tube connection hole 13, expansion and contraction groove 14, water Jet booster water pipe connection port 15, nozzle core outer cone surface 16, nozzle core water inlet hole 17, etc.

[0025] Such as Figure 1~6 As shown, the present invention is an adjustable multi-stage pressurized water jet nozzle, including a nozzle core 3 and an inner cone sleeve 6 threadedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com