A method for rapidly preparing high-strength carbon foam

A carbon foam, high-strength technology, applied in chemical instruments and methods, carbon preparation/purification, ceramic products, etc., can solve the problems of wide application limitation, increase preparation cost, limit high-strength carbon foam, etc., and achieve a simple process route. , The effect of shortening the preparation cycle and lowering the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

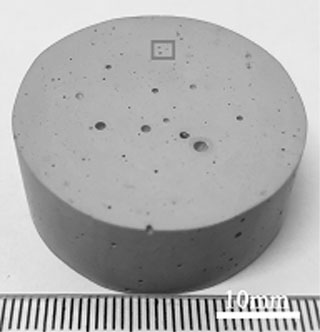

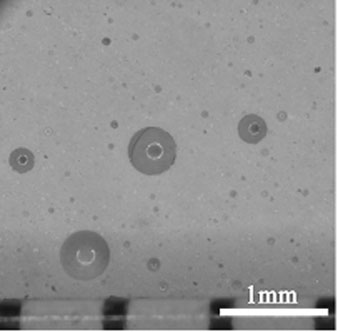

Embodiment 1

[0037] (1) To prepare carbon foam with a specific gravity of resin and quartz of 3:1, first prepare 15 g of thermosetting phenolic resin (viscosity: 16000~19000 MP / 25°C; residual carbon rate: 40~45%; purity: 99%), The particle size is 2000 mesh quartz powder 5 g (main component: SiO 2 , purity: 99%), the quartz powder was dried in a box-type resistance furnace at 100 °C for 1 h and used for later use;

[0038](2) Pour the phenolic resin into the mortar, slowly add the quartz powder, and keep stirring, stop stirring for more than 30 minutes, add a small amount of curing agent (benzenesulfonic acid), and continue stirring for 8-10 minutes until the slurry is mixed For a viscous state, pour the prepared mixed slurry into a prefabricated cylindrical mold;

[0039] (3) Put the prefabricated embryo body slurry in the air at room temperature, and let it stand for 24 hours until the embryo body slurry is solidified and shaped;

[0040] (4) Place the solidified foam embryo in a box-t...

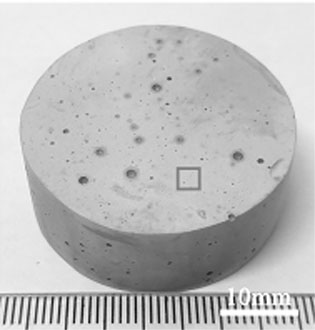

Embodiment 2

[0046] (1) To prepare carbon foam with a specific gravity of resin and quartz of 1:1, first prepare 10 g of thermosetting phenolic resin (viscosity: 16000~19000 MP / 25℃; residual carbon rate: 40~45%; purity: 99%), The particle size is 2000 mesh quartz powder 10 g (main component: SiO 2 , purity: 99%), the quartz powder was dried in a box-type resistance furnace at 100 °C for 1 h and used for later use;

[0047] (2) Pour the phenolic resin into the mortar, slowly add the quartz powder, and keep stirring, stop stirring for more than 30 minutes, add a small amount of curing agent (benzenesulfonic acid), and continue stirring for 8-10 minutes until the slurry is mixed For a viscous state, pour the prepared mixed slurry into a prefabricated cylindrical mold;

[0048] (3) Put the prefabricated embryo body slurry in the air at room temperature, and let it stand for 24 hours until the embryo body slurry is solidified and shaped;

[0049] (4) Place the solidified foam embryo in a box-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com