Nanoscale fish oil microcapsule as well as preparation method and application thereof

A microcapsule and nanoscale technology, which is applied to nanoscale fish oil microcapsules and a preparation method and application field thereof, can solve the problems of reducing the oxidation rate of omega-3 unsaturated fatty acids, long homogenization time, etc., and achieves breakthroughs in application barriers and increases Shelf life, easy to accept effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]This example is a method for preparing nano-scale fish oil microcapsules according to the present invention. The microwave catalytic homogenization method is used to prepare the nano Grade fish oil microcapsules; Described preparation method specifically comprises the steps:

[0040] (1) 1g of surfactant Tween 20 (Tween20) is mixed with fish oil in a mass ratio of 1:1, and then mixed with 8ml of water to obtain a mixture with a concentration of 0.2g / ml;

[0041] (2) Put the mixture described in step (1) into microwave catalysis equipment, then put the homogenizer made of plastic into the mixture described in step (1) from the microwave catalysis equipment upper end, then carry out microwave catalysis and homogenization quality, the microwave power of microwave catalytic equipment is 100Hz, the speed of homogenization is 9000r / min, the time of microwave catalysis and homogenization is 5min, and the mixed solution is obtained;

[0042] (3) freeze-drying the mixed solution...

experiment example 1

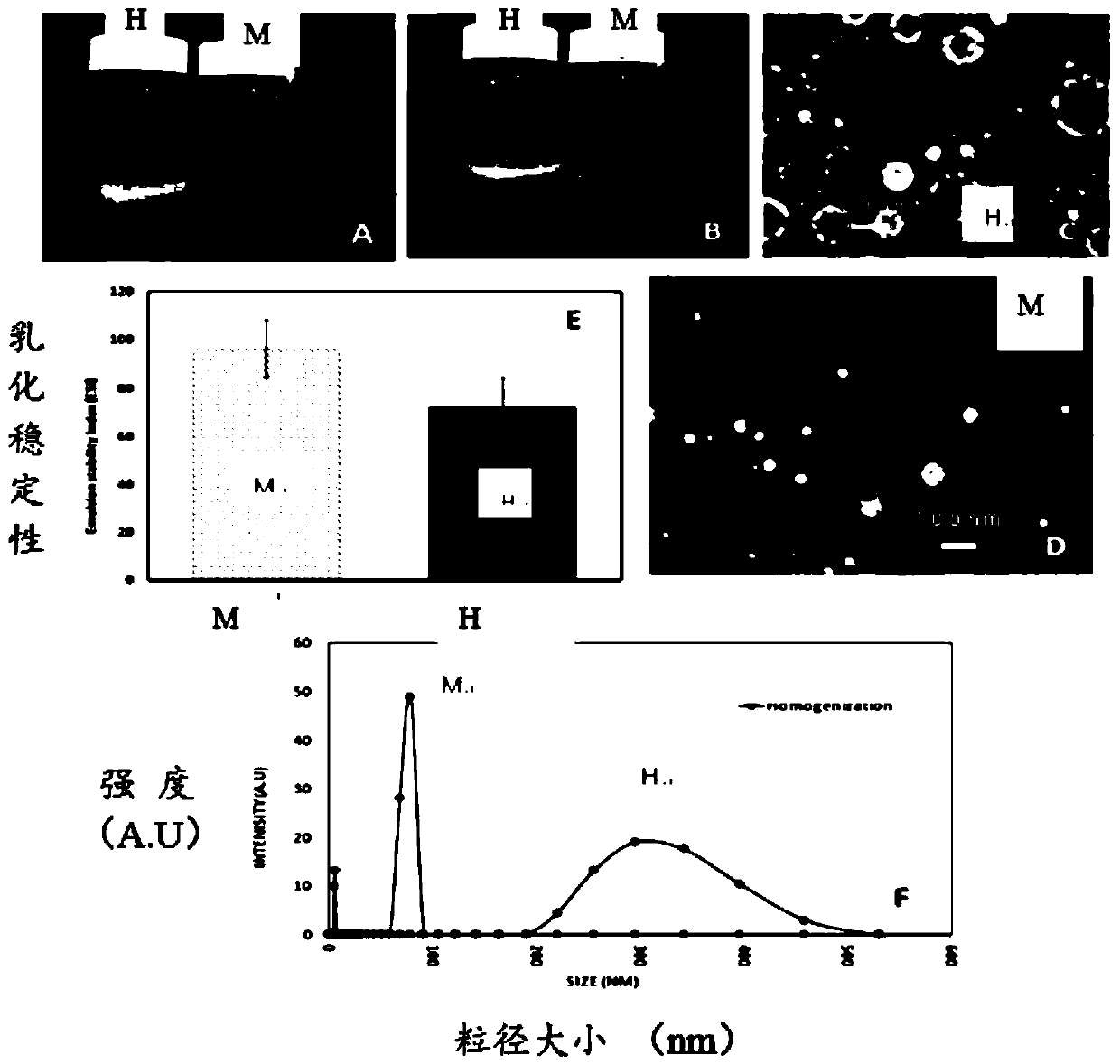

[0049] The fish oil microcapsules obtained by adopting the preparation method of Example 1 of the present invention and Comparative Example 1 are compared, and the comparison results are as follows: figure 1 shown.

[0050] (1), observe the fish oil microcapsules that adopt the preparation method of embodiment 1 of the present invention and comparative example 1 to obtain, and just prepare and obtain the result of immediate observation as follows figure 1 Shown in (A), the result observed after placing 48h after preparation is as follows figure 1 (B) shown.

[0051] Observation results: figure 1 (A) The appearance of the fish oil microcapsules prepared by the preparation method described in H Comparative Example 1, figure 1 M in (A) is the appearance of the nanoscale fish oil microcapsules prepared by the preparation method described in Example 1; figure 1 The appearance of the fish oil microcapsules prepared by the preparation method described in H Comparative Example 1 i...

experiment example 2

[0059] This experimental example is the detection of the content of omega-3 unsaturated fatty acids in fish oil microcapsules / nanoscale fish oil microcapsules. The detection method includes the following steps:

[0060] (1) Extract the fat in the fish oil microcapsules / nanoscale fish oil microcapsules, convert the fat into fatty acid methyl esters according to conventional methods, and then separate the fatty acid methyl esters;

[0061] (2) detect the content of fatty acid methyl ester described in step (1) in gas chromatography equipment, the content of described fatty acid methyl ester is the content of described omega-3 unsaturated fatty acid; The content of described fatty acid methyl ester The detection conditions in the gas chromatography equipment are: the surface of the capillary column is coated with cyanopropylpolysilylphenylsiloxane with a thickness of 0.25mm and a mass concentration of 70%, and the length of the capillary column is 50cm and the inner diameter is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com