Preparation method of instant powder tea

A production method and technology of instant tea, applied in tea, tea extraction, tea spices, etc., can solve the problems of insufficient clarification of tea soup, low aroma, poor cold solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

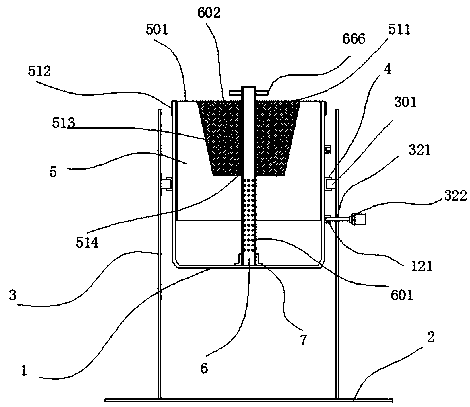

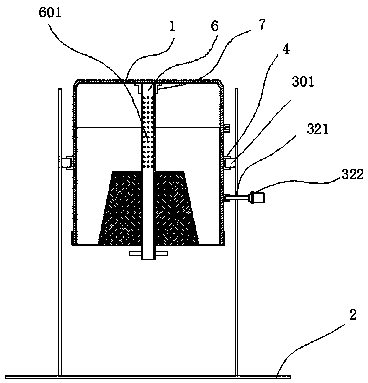

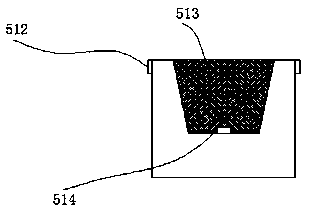

Image

Examples

Embodiment 1

[0050] 1) Select fresh tea leaves, put the selected tea leaves in a special container, and then inject water with a large flow rate. When the water is about to overflow, change it to a small flow rate of water, so that the water in the container overflows. After 2 hours of water injection, Then take out the tea leaves and dry them out, and keep the water in the container always in a state of replacement by maintaining a small flow of water, and remove the pesticide residues attached to the surface of the tea leaves;

[0051] 2) Take out the tea leaves after cleaning in step 1), and expose them to the sun until the water content is 12%;

[0052] 3) Put the tea leaves that have been dried in step 2) into a microwave de-enzyming machine for de-enzyming, and the de-enzyming time is 3 minutes; after de-enzyming, the water content in the tea leaves is 2.5%;

[0053] 4) After finishing, quickly put the tea into the cold storage for cooling, the cooling temperature is -30~, and the co...

Embodiment 2

[0063] 1) Select fresh tea leaves, put the selected tea leaves in a special container, and then inject water with a large flow rate. When the water is about to overflow, change it to a small flow rate of water, so that the water in the container overflows. After 2 hours of water injection, Then take out the tea leaves and dry them out, and keep the water in the container always in a state of replacement by maintaining a small flow of water, and remove the pesticide residues attached to the surface of the tea leaves;

[0064] 2) Take out the tea leaves after cleaning in step 1), and expose them to the sun until the water content is 11%;

[0065] 3) Put the tea leaves that have been dried in step 2) into a microwave de-enzyming machine for de-enzyming, and the de-enzyming time is 5 minutes; the water content in the de-enzymed tea leaves is 1.75%;

[0066] 4) After finishing, quickly put the tea into the cold storage for cooling, the cooling temperature is -45°C, and the cooling ...

Embodiment 3

[0076] 1) Select fresh tea leaves, put the selected tea leaves in a special container, and then inject water with a large flow rate, and when the water is about to overflow, change to a small flow rate of water, so that the water in the container overflows, and inject water for 1~2 hours Finally, the tea leaves are taken out and controlled to dry. By maintaining a small flow of water, the water in the container is always in a state of replacement, and the pesticide residues attached to the surface of the tea leaves are removed;

[0077] 2) Take out the tea leaves after cleaning in step 1), and expose them to the sun until the water content is less than 13%;

[0078] 3) Put the tea leaves that have been dried in step 2) into a microwave de-enzyming machine for 3-5 minutes; the main purpose of de-enzyming is to destroy and passivate the oxidase activity in fresh leaves through high temperature, and inhibit fresh leaves Enzymatic oxidation of tea polyphenols in the tea to prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com