Miniaturized and circularly polarized patch antenna

A patch antenna and patch technology, applied in antennas, loop antennas, antenna coupling and other directions, can solve the problems of complex overall structure of the antenna, increase manufacturing costs, and are not adjustable, save manufacturing costs and R&D cycles, and improve antenna radiation. performance, resisting the effect of matching interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

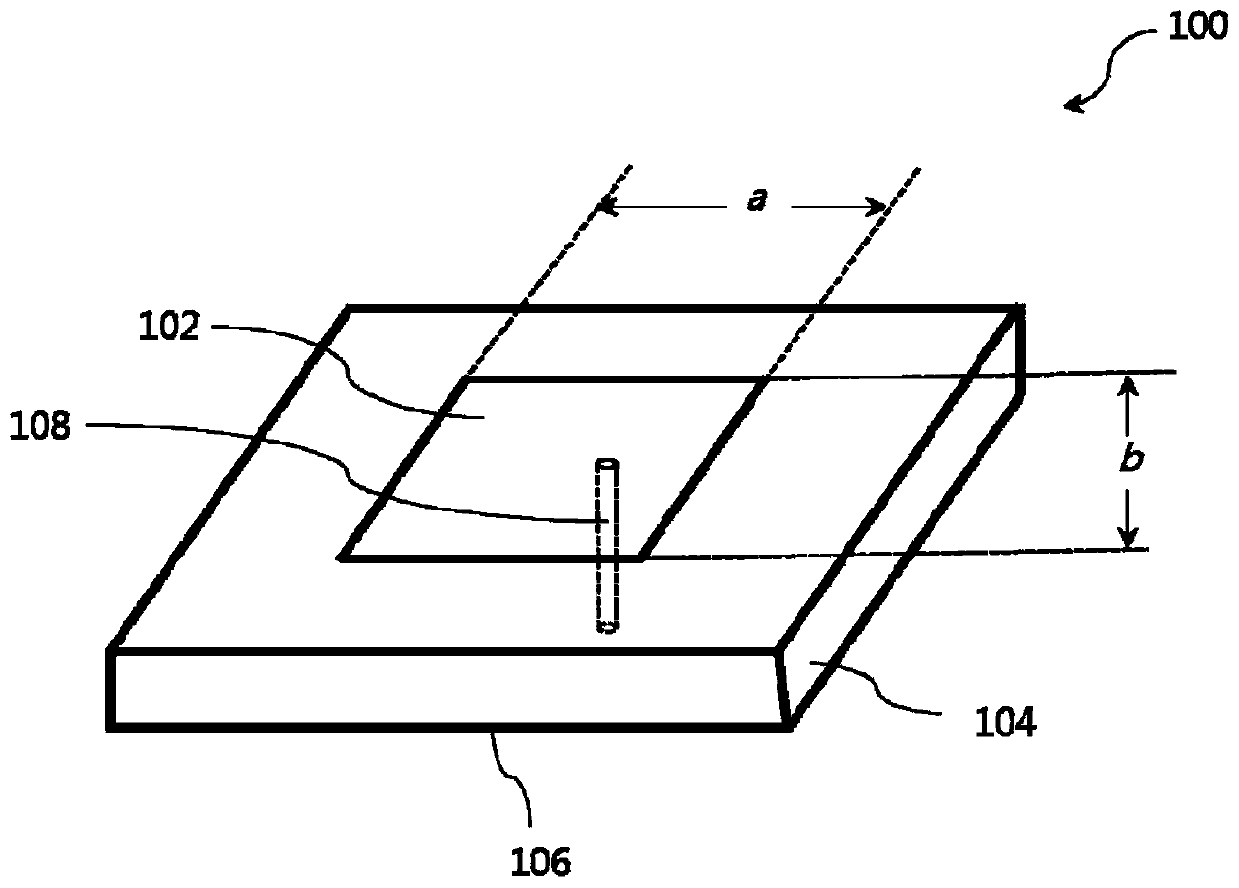

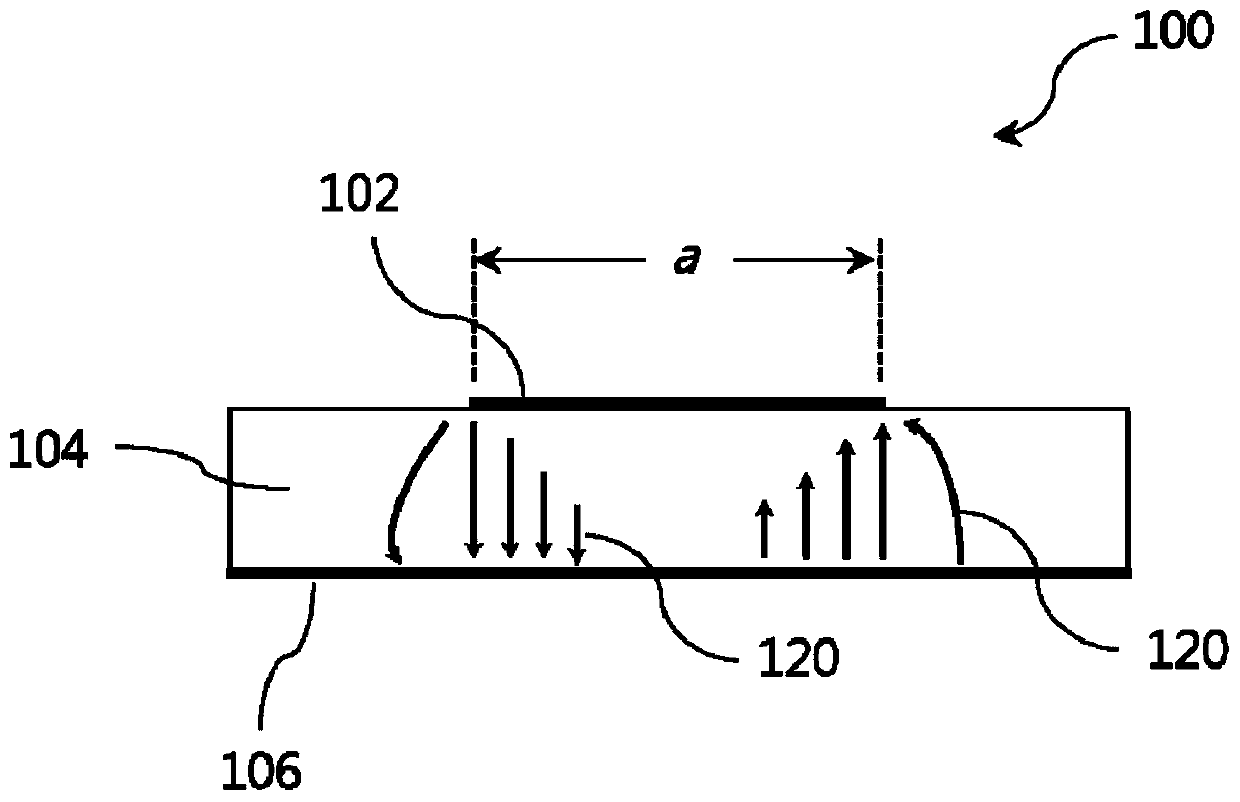

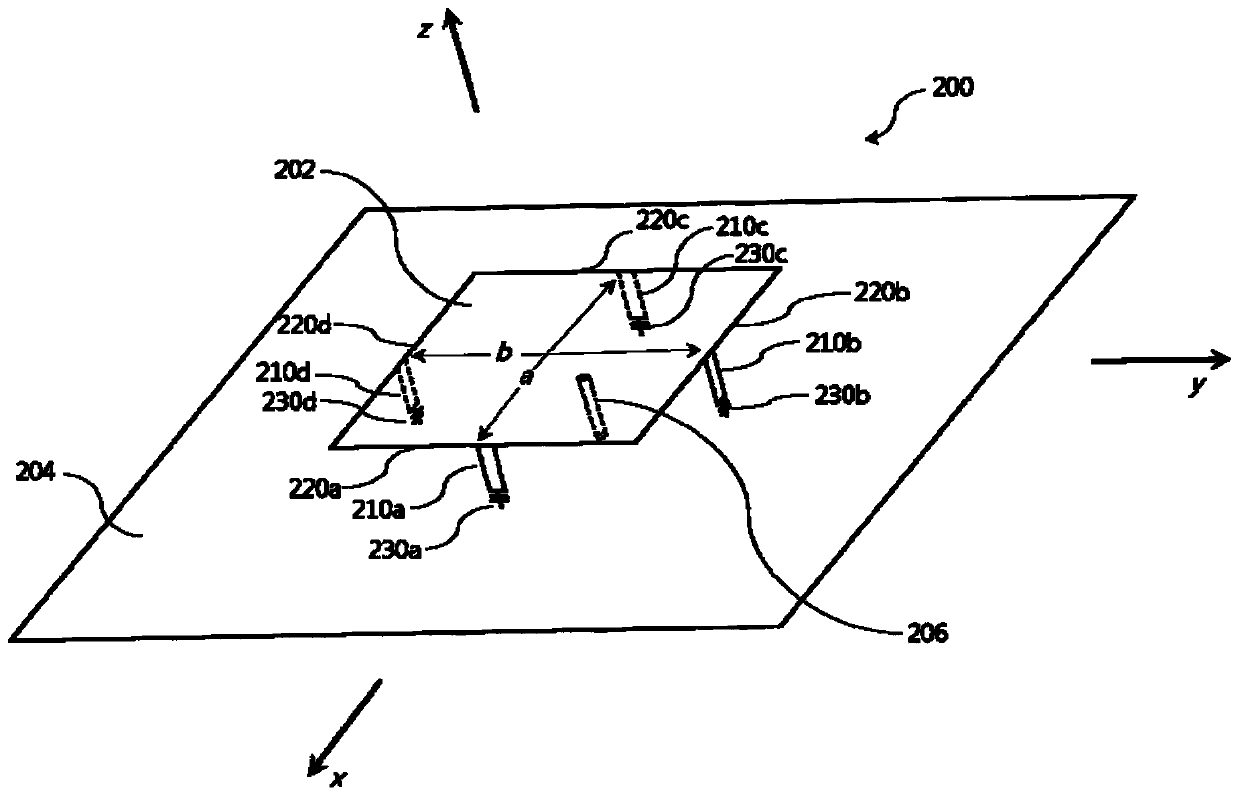

[0055] figure 2 It is a three-dimensional structural schematic diagram of the miniaturized and circularly polarized patch antenna in Embodiment 1 of the present invention.

[0056] Such as figure 2 As shown, a miniaturized and circularly polarized patch antenna 200 includes a rectangular patch 202, a ground plate 204 formed under the rectangular patch 202, and a first first side 220a electrically connected to the rectangular patch 202. The metal connecting wire 210a, the second metal connecting wire 210b electrically connected to the second side 220b of the rectangular patch 202, the third metal connecting wire 210c electrically connected to the third side 220c of the rectangular patch 202, and the third metal connecting wire 210c electrically connected to the rectangular patch 202 The fourth metal connection line 210d on the fourth side 220d of the patch 202, the first side 220a of the rectangular patch 202 is opposite to the third side 220c of the rectangular patch 202, t...

Embodiment 2

[0092] Figure 7 It is a three-dimensional schematic diagram of the miniaturized and circularly polarized patch antenna in Embodiment 2 of the present invention.

[0093] Please combine Figure 7 , and refer to figure 2 , Figure 7 A miniaturized and circularly polarized patch antenna 700 is shown, including a ground plane 704, a cross-shaped patch 702 formed above the ground plane, and a first metal connecting line 710a, a second metal connecting line 710b, a third Metal connection line 710c, fourth metal connection line 710d. The cross-shaped patch 702 can be composed of two rectangular patches that are orthogonal to each other to form a cross shape, or can be integrally formed, and its lengths are a and b respectively, wherein the length a corresponds to the first side and the second side of the cross-shaped patch 702 Three sides, the length b corresponds to the second side and the fourth side of the cross-shaped patch 702 . The first metal connection line 710a is ele...

Embodiment 3

[0098] Figure 8 It is a three-dimensional schematic diagram of the miniaturized and circularly polarized patch antenna in Embodiment 3 of the present invention.

[0099] Please combine Figure 8 , and refer to figure 2 , Figure 8 A miniaturized and circularly polarized patch antenna 800 is shown, including a ground plate 804, an oval patch 802, a first metal connection line 810a, a second metal connection line 810b, a third metal connection line 810c, a fourth Metal connection wire 810d. The lengths of the major axis and the minor axis of the elliptical patch 802 are a and b respectively, the two ends of the length a correspond to the first side and the third side of the elliptical patch 802, and the two ends of the length b correspond to the elliptical patch 802 the second and fourth sides of the The first metal connection line 810a is electrically connected to the first side of the oval patch 802, the second metal connection line 810b is electrically connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com